1ST TERM

1ST TERM

SCHEME OF WORK

WEEK TOPIC

1. Revision of second year work

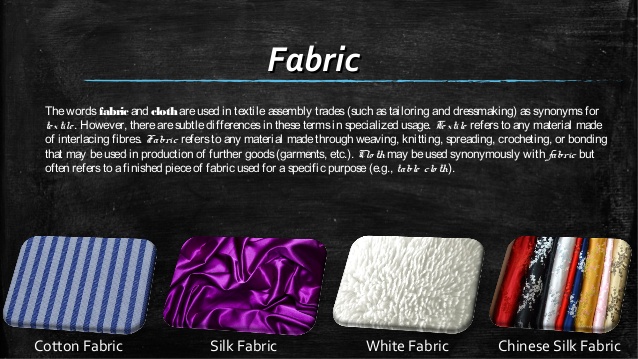

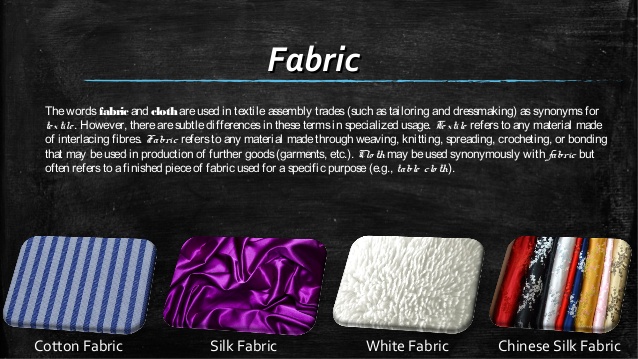

2. Introduction to Textiles study: (a) Basic textiles terms e.g. fibre, yarn, warp, weft, fabric. (b)Reasons for studying textiles. (c)General uses of textiles. (d) Weaving.

3. Classes and properties of fibres: (a) classification of fibres. (b) Properties of fibres. (c) Making of textile album.

4. Manufacture, Identification and uses of fabrics: (a) Manufacture of fabrics fibres. (b) Fabric identification methods. (c) Uses of fabrics.

5-6. Care of Different fabrics:

(a) Care of different fabrics.

(b) Factors to consider in laundering a fabric

(c) laundry agents and equipment. (d) Laundry processes.

7. Basic Elements in Design: (a) Basic elements of design. (b) Colour wheel and harmony. Making patterns using lines

8. Figure Types: (a) Different figure types (b) Figure problems or faults. (c) Ways of solving figure problems or faults.

9. The sewing machine: (a) Types of sewing machines (b) parts of the sewing machines and their functions. (c) Guidelines for choosing sewing machine.

10. The sewing machine: (e) How to use sewing machine. (f) Care of sewing machines.

11. Revision.

WEEK TOPIC

1. Revision of second year work

2. Introduction to Textiles study: (a) Basic textiles terms e.g. fibre, yarn, warp, weft, fabric. (b)Reasons for studying textiles. (c)General uses of textiles. (d) Weaving.

3. Classes and properties of fibres: (a) classification of fibres. (b) Properties of fibres. (c) Making of textile album.

4. Manufacture, Identification and uses of fabrics: (a) Manufacture of fabrics fibres. (b) Fabric identification methods. (c) Uses of fabrics.

5-6. Care of Different fabrics:

(a) Care of different fabrics.

(b) Factors to consider in laundering a fabric

(c) laundry agents and equipment. (d) Laundry processes.

7. Basic Elements in Design: (a) Basic elements of design. (b) Colour wheel and harmony. Making patterns using lines

8. Figure Types: (a) Different figure types (b) Figure problems or faults. (c) Ways of solving figure problems or faults.

9. The sewing machine: (a) Types of sewing machines (b) parts of the sewing machines and their functions. (c) Guidelines for choosing sewing machine.

10. The sewing machine: (e) How to use sewing machine. (f) Care of sewing machines.

11. Revision.

Week 1

TOPIC: Manufacture, Identification and uses of fabrics.

CONTENT: 1. Manufacture of fabrics fibre

ii.Fabric identification methods, Uses of fabrics.

Sub-Topic 1: Manufacture of fabrics fibre

Manufacturing process of cotton fibres:

Cotton fabrics are processed from the bolls by the following step:

1. Ginning: This is the process of separating or removing cotton fibres from the seeds. The hairs left on the seeds after ginning are called linters.

2. Baling: The ginned cotton is pressed into bales. The bales are sent to factory or mill.

3. Cleaning: The impurities in the cotton are removed in the mill.

4. Carding: At this stage, many shorter fibres are removed. The longer ones are formed into thick ropes. The ropes are called slivers.

5. Combing: This is the process of removing more short fibres.

6. Drawing: This is the process of twisting the ropes and making them ready for spinning.

7. Spinning: This is the process of making the twisted into yarn or thread.

8. Dyeing: The yarn can be bleached or dyed into different colours and woven into fabrics.

9. Weaving: the yarns are used to produce fabrics.

Cotton plant with cotton boll

[youtube]https://www.youtube.com/watch?v=orKBbm9lJ1s[/youtube]

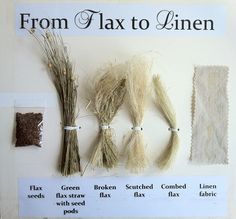

Manufacturing process of linen:

Linen is processed from the stem of flax plant by the following steps:

i. Retting: This is the process of softening the flax stems by letting them rot in ponds or special retting tanks. This separates the fibres from the stem.

ii. Breaking and scotching: These are mechanical treatments that break and remove the woody matter and impurities from the fibres.

iii. Combing: This is the process of passing the fibres through special series of combs to separate long fibres from short ones.

iv. Spinning: This is the process of drawing the fibres into slivers and twisting them for strength. Yarns are produced. The yarns are then woven into fabric.

v. The yarns can be dyed before weaving.

Flax plant

[youtube]https://www.youtube.com/watch?v=nspGz6xYzvg[/youtube]

[youtube]https://www.youtube.com/watch?v=-ZrZZefkohE[/youtube]

Manufacturing process for wool:

Wool fibres are processed into two forms:

1. Worsted yarn; This is made from long fibres.

2. Woolen yarn: This is made from short fibres.

The major steps for the manufacturing of both forms are:

i. Clipping: the fibres (fleece) from the sheep. This is cutting the hair. The fleece is then packed in bales and transported to the factories.

ii. Sorting: The process of grading and separating fibres according to length.

iii. Scouring: The process of washing the fibres in soapy alkaline water to remove dirt and grease.

iv. Carbonizing: The process of removing all vegetable matter from the fibres by treatment with acid heat and pressure.

v. Carding: This process separates the matted fibres.

vi. Spinning: This is the process of twisting the fibres into worsted or woolen yarns.

vii. Weaving: The process of making the wool fabrics from the yarn.

Sheep with wool/Shearing

[youtube]https://www.youtube.com/watch?v=9UqhGlOaXwY[/youtube]

Manufacturing process for silk:

A silk worm spins filaments (the fibres) for its cocoon. It then turns into pupa. The fibres are then held together by silk gum. Before the pupa changes into a moth, the cocoon is put into boiling water. This softens the gum.the silk fibre is then drawn from the cocoon. The raw silk is reeled up into skeins and packed into small bundles called books. Silk fibre is very fine or tiny to handle. Therefore, silk is processes by the following steps.

Throwing: this is the process of twisting silk fibres to form a strong yarn.

De-gumming: this is the process of removing the silk-gum from the yarn by boiling in soapy water.

Weaving: this is the process of constructing the yarn into silk fabric. Metallic salts in a process known as weighing. This makes the fabric heavier.

Oak silkworm cocoon

[youtube]https://www.youtube.com/watch?v=klZeS-g0UHo[/youtube]

Manufacturing process of Rayon:

1. The cellulose (wood pulp or cotton linters) is first purified.

2. The cellulose is then treated with the right chemicals. It is then changed into a thick liquid.

3. The liquid is then forced through a nozzle containing many fine holes called a spinneret. The rayon filament or fibres are produced.

4. The filaments are spun into yarns. The yarns are woven into fabric.

Spinneret with filament

[youtube]https://www.youtube.com/watch?v=YYWlevX7Kw0[/youtube]

Manufacturing procedure of acetate:

1. The cellulose is purified.

2. It is treated with acetic acid and acetic anhydride, then with water. Cellulose acetate is formed.

3. Cellulose acetate is dissolved in acetone to form a thick liquid.

4. The liquid is spun into filaments or fibres.

[youtube]https://www.youtube.com/watch?v=j8jR7mFsans[/youtube]

Manufacturing of nylon:

Nylon is made through a complex series of chemical processes, using coal or petroleum, water and air. It can be made into continuous filaments or short lengths (staple yarn)

[youtube]https://www.youtube.com/watch?v=HTh_5CWMSoQ[/youtube]

Fabric finishes

Fabric finishes are treatments given to fabrics after construction. These finishes help to improve the appearance and handle of the fabrics. They can also affect the care required by the fabric. These include:

1. Luster or sheen finishes: these give a glossy or lustrous appearance to fabrics. E.g. are,

a. Mercerization: treating cotton with caustic soda to make it lustrous.

b. Glazing; treating fabrics (e.g. cotton) with stiffening agents such as gums shiny or glazed surface.

2. Drip-dry finish; this is an easy-care finish. It helps to prevent creasing or wrinkling. Fabrics given drip-dry finish do not require ironing.

3. Crease-resistant finishes: these are given to fabrics that crease easily. They prevent creasing.

4. Shrink-resistant finishes: these control the amount of shrinkage which a fabric will undergo when washed.

5. Water-repellant finishes; these make fabrics resist wetting by water.

6. Flame- resistant finishes; these prevent fabrics from flaring and burning up quickly.

7. Moth-proof finishes; these prevent fabrics from being attacked by moth.

[youtube]https://www.youtube.com/watch?v=lnQMLF9u5eU[/youtube]

Evaluation:

1. Outline the steps in the manufacturing of:

i. Silk

ii. Cotton

2. list and explain 4 fabric finishes

Reading Assignment:

Popoola O.O. Home Economics New Concepts for JSS Book 3 Pages 1-14

CONTENT: 1. Manufacture of fabrics fibre

ii.Fabric identification methods, Uses of fabrics.

Sub-Topic 1: Manufacture of fabrics fibre

Manufacturing process of cotton fibres:

Cotton fabrics are processed from the bolls by the following step:

1. Ginning: This is the process of separating or removing cotton fibres from the seeds. The hairs left on the seeds after ginning are called linters.

2. Baling: The ginned cotton is pressed into bales. The bales are sent to factory or mill.

3. Cleaning: The impurities in the cotton are removed in the mill.

4. Carding: At this stage, many shorter fibres are removed. The longer ones are formed into thick ropes. The ropes are called slivers.

5. Combing: This is the process of removing more short fibres.

6. Drawing: This is the process of twisting the ropes and making them ready for spinning.

7. Spinning: This is the process of making the twisted into yarn or thread.

8. Dyeing: The yarn can be bleached or dyed into different colours and woven into fabrics.

9. Weaving: the yarns are used to produce fabrics.

Cotton plant with cotton boll

[youtube]https://www.youtube.com/watch?v=orKBbm9lJ1s[/youtube]

Manufacturing process of linen:

Linen is processed from the stem of flax plant by the following steps:

i. Retting: This is the process of softening the flax stems by letting them rot in ponds or special retting tanks. This separates the fibres from the stem.

ii. Breaking and scotching: These are mechanical treatments that break and remove the woody matter and impurities from the fibres.

iii. Combing: This is the process of passing the fibres through special series of combs to separate long fibres from short ones.

iv. Spinning: This is the process of drawing the fibres into slivers and twisting them for strength. Yarns are produced. The yarns are then woven into fabric.

v. The yarns can be dyed before weaving.

Flax plant

[youtube]https://www.youtube.com/watch?v=nspGz6xYzvg[/youtube]

[youtube]https://www.youtube.com/watch?v=-ZrZZefkohE[/youtube]

Manufacturing process for wool:

Wool fibres are processed into two forms:

1. Worsted yarn; This is made from long fibres.

2. Woolen yarn: This is made from short fibres.

The major steps for the manufacturing of both forms are:

i. Clipping: the fibres (fleece) from the sheep. This is cutting the hair. The fleece is then packed in bales and transported to the factories.

ii. Sorting: The process of grading and separating fibres according to length.

iii. Scouring: The process of washing the fibres in soapy alkaline water to remove dirt and grease.

iv. Carbonizing: The process of removing all vegetable matter from the fibres by treatment with acid heat and pressure.

v. Carding: This process separates the matted fibres.

vi. Spinning: This is the process of twisting the fibres into worsted or woolen yarns.

vii. Weaving: The process of making the wool fabrics from the yarn.

Sheep with wool/Shearing

[youtube]https://www.youtube.com/watch?v=9UqhGlOaXwY[/youtube]

Manufacturing process for silk:

A silk worm spins filaments (the fibres) for its cocoon. It then turns into pupa. The fibres are then held together by silk gum. Before the pupa changes into a moth, the cocoon is put into boiling water. This softens the gum.the silk fibre is then drawn from the cocoon. The raw silk is reeled up into skeins and packed into small bundles called books. Silk fibre is very fine or tiny to handle. Therefore, silk is processes by the following steps.

Throwing: this is the process of twisting silk fibres to form a strong yarn.

De-gumming: this is the process of removing the silk-gum from the yarn by boiling in soapy water.

Weaving: this is the process of constructing the yarn into silk fabric. Metallic salts in a process known as weighing. This makes the fabric heavier.

Oak silkworm cocoon

[youtube]https://www.youtube.com/watch?v=klZeS-g0UHo[/youtube]

Manufacturing process of Rayon:

1. The cellulose (wood pulp or cotton linters) is first purified.

2. The cellulose is then treated with the right chemicals. It is then changed into a thick liquid.

3. The liquid is then forced through a nozzle containing many fine holes called a spinneret. The rayon filament or fibres are produced.

4. The filaments are spun into yarns. The yarns are woven into fabric.

Spinneret with filament

[youtube]https://www.youtube.com/watch?v=YYWlevX7Kw0[/youtube]

Manufacturing procedure of acetate:

1. The cellulose is purified.

2. It is treated with acetic acid and acetic anhydride, then with water. Cellulose acetate is formed.

3. Cellulose acetate is dissolved in acetone to form a thick liquid.

4. The liquid is spun into filaments or fibres.

[youtube]https://www.youtube.com/watch?v=j8jR7mFsans[/youtube]

Manufacturing of nylon:

Nylon is made through a complex series of chemical processes, using coal or petroleum, water and air. It can be made into continuous filaments or short lengths (staple yarn)

[youtube]https://www.youtube.com/watch?v=HTh_5CWMSoQ[/youtube]

Fabric finishes

Fabric finishes are treatments given to fabrics after construction. These finishes help to improve the appearance and handle of the fabrics. They can also affect the care required by the fabric. These include:

1. Luster or sheen finishes: these give a glossy or lustrous appearance to fabrics. E.g. are,

a. Mercerization: treating cotton with caustic soda to make it lustrous.

b. Glazing; treating fabrics (e.g. cotton) with stiffening agents such as gums shiny or glazed surface.

2. Drip-dry finish; this is an easy-care finish. It helps to prevent creasing or wrinkling. Fabrics given drip-dry finish do not require ironing.

3. Crease-resistant finishes: these are given to fabrics that crease easily. They prevent creasing.

4. Shrink-resistant finishes: these control the amount of shrinkage which a fabric will undergo when washed.

5. Water-repellant finishes; these make fabrics resist wetting by water.

6. Flame- resistant finishes; these prevent fabrics from flaring and burning up quickly.

7. Moth-proof finishes; these prevent fabrics from being attacked by moth.

[youtube]https://www.youtube.com/watch?v=lnQMLF9u5eU[/youtube]

Evaluation:

1. Outline the steps in the manufacturing of:

i. Silk

ii. Cotton

2. list and explain 4 fabric finishes

Reading Assignment:

Popoola O.O. Home Economics New Concepts for JSS Book 3 Pages 1-14

Week 2

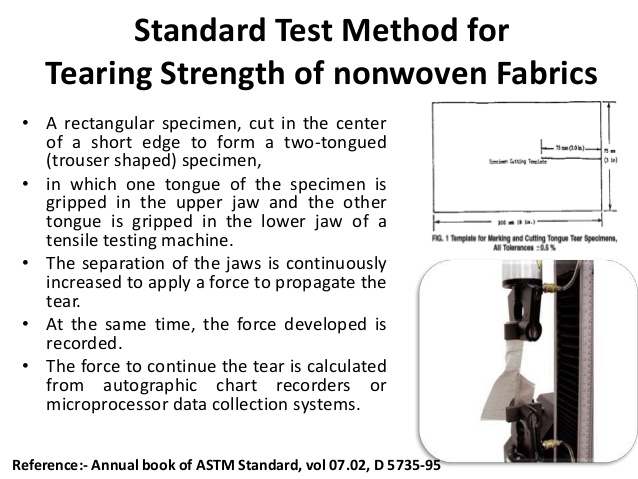

Sub-Topic 2: Fabric identification methods, Uses of fabrics.

Fabric identification methods:

Identification is the process of recognizing the different fabrics. Sometimes labels on fabrics give details of the type of fabrics and how to care for them. In some cases, the labels are not available. Also many fabrics resemble one another in appearance and feel. Thus it becomes necessary that one knows how to identify fabrics by using identification tests like the following:

The different identification tests are;

1. strength test

2. microscope test

3. burning tests

4. appearance and handling

Strength test: this is done to test both the wet and dry strength of fabrics.

Apparatus needed:

i. Two warp yarns of each fabric to be tested.

ii. A bowl of cold water.

Procedure:

i. Soak one of the yarns in a bowl of cold water.

ii. Bring it out of the water and pull with both hands.

iii. Repeat with the dry yarn. Find out if wet one is either stronger, weaker or the same as the dry one.

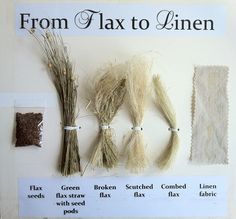

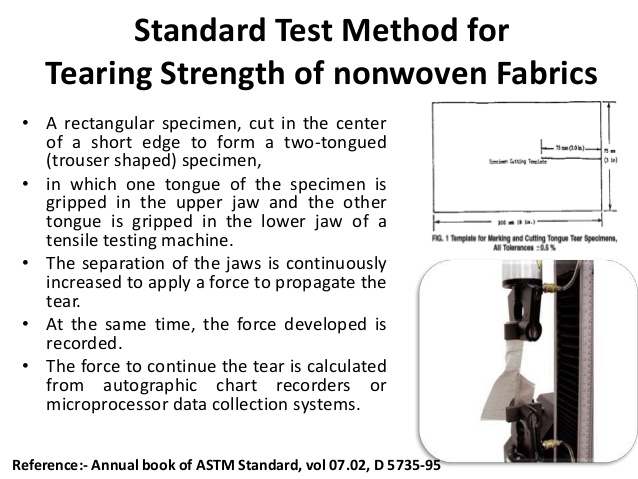

Microscopic test: this is a test to study the structure of the fabric under a microscope.

Apparatus needed:

i. Microscope

ii. High and low power lenses.

iii. A slide.

iv. Fabric yarns.

v. Cellotape

Procedure:

i. Mount the yarn on a slide.

ii. Examine under low power lenses. Repeat under high power lenses.

iii. Observations should centre on the shape of the fibre (flat or round) as well as markings on it.

Burning test: this is the process of holding yarns over a flame of a lighted candle, match or gas

burner.

Apparatus needed:

i. Bunsen burner stove or candle.

ii. Matches.

iii. Small pieces of different materials.

iv. A crucible.

Procedure:

i. Light the Bunsen burner, stove or candle.

ii. Hold the material or fabric over the flame and withdraw immediately.

Observations to be made are:

i. Whether the yarn

(a) burns

(b) continues to burn out the flame

(c) Shrinks form flame and melts.

(d) Melts and burns.

ii. The type of smell from the fumes.

iii. The nature of the ash.

Appearance and handling: this is the physical look and the feel of the material when touched by hand. Appearance and handling are not dependable tests, because many fabrics can have similar appearance and handling.

Identification tests of different fabrics:

1. Wool:

(a) Strength test: stronger when dry than wet

(b) Microscopic test: i. long and cylindrical appearance. ii. fibre covered with scale pointing in one direction.

(c) Burning test: i. smolders ii. Smells like burning hair or feathers. Iii. Leaves porous crushable carbon beads.

(d) Appearance and Handling: i. has lots of hair on its surface. ii. Warm and elastic quality. iii. Very little luster.

2. Silk:

(a) Strength test: weaker when wet than dry

(b) Burning test: i. smells like burning feather or hair ii. Shrivels and burns slowly

(c) Microscopic test: i. appears long, smooth and rod-like ii. Reflects light readily

(d) Appearance and Handling; i. smooth and shiny ii. Feels cool to touch

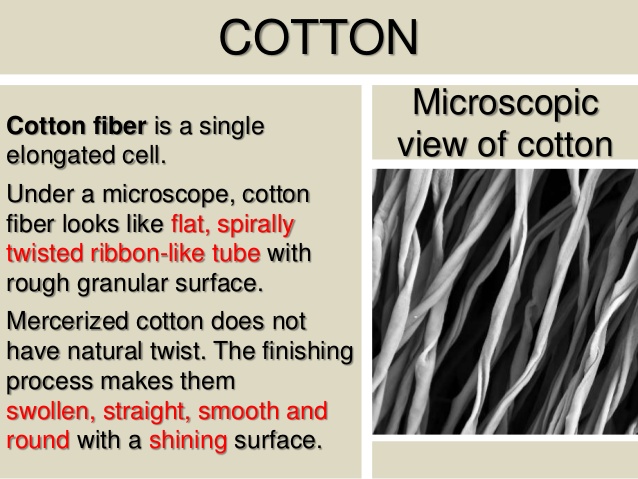

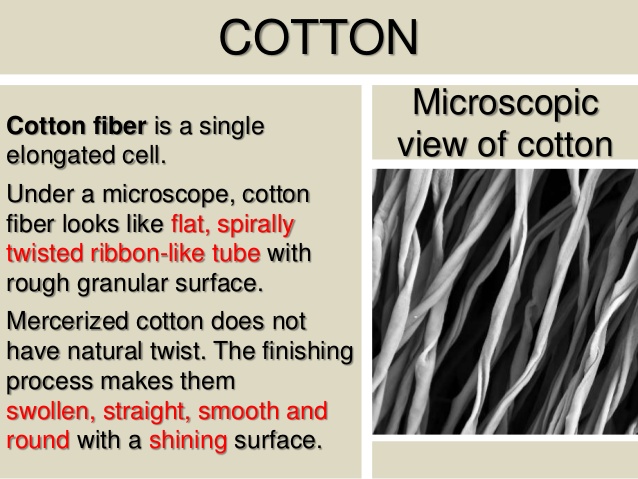

3. Cotton:

(a) Strength test; i. firm and strong when dry ii. Strong when wet

(b) Microscopic test: i. fibre has twists ii. Fibre has flat long appearance

(c) Burning test: i. burns easily, in and out of flame. ii. Smells like burning paper. iii. Leaves a grey powder.

(d) Appearance and Handling; i. smooth without luster, ii. Creases iii. cool to touch

4. Viscose Rayon;

(a) Strength test: stronger when dry than wet

(b) Microscopic test; resembles silk

(c) Burning test; i. burns readily ii. deposits white ashy spots

(d) Appearance and Handling: i. smooth ii creases badly

5. Acetate:

(a) Strength test: stronger when wet than dry

(b) Microscope test: similar to viscose rayon

(c) Burning test: i. burns slowly in and out of flame. ii. smells like acetic acid or vinegar.

6. Linen:

(a) Strength test: i. very strong naturally ii. stronger when wet than dry

(b) Microscopic test: smooth rounded appearance with nodes or swellings at regular intervals

(c) Burning test: i. burns easily in out of flame ii. leaves a feathery white ash iii. smells like burning paper.

(d) Appearance and Handling: i. cool smooth feel ii. Has luster iii. creases easily

7. Nylon:

(a) Strength test: no difference when wet or dry

(b) Microscope test: long thin fibre with clear central tube

(c) Burning test: i. shrinks from flame ii fumes smell like boiling celery iii. melts into white hard beads.

(d) Appearance and Handling: i. drapes easily ii. creases resistant iii. smooth surface

8. Polyester:

(a) Strength test: no difference

(b) Microscopic test: rod-like, smooth and cylindrical in appearance

(c) Burning test: i. melts and shrinks from flame ii. burns on in flame iii. forms hard beads

(d) Appearance and Handling: i. smooth and soft to touch ii. crease resistant

Uses of fabrics

Different fabrics are suitable for different purposes.

1. Cotton fabrics can be used for outer personal clothes, underwear, furnishings, bed sheets, pillow cases, tablecloth etc.

2. Linen can be used into different articles such as kitchen linen, like glass-cloth, tea-towels, table-covers, tray cover, serviette, suits, dresses, etc.

3. Wool can be used be used for under wears, sweaters, socks, suits, trousers, vests, baby wears, soft furniture, etc. they are particularly suitable for cold weathers and temperate countries.

4. Silk fabrics are used for making scarves, tiles, dresses, shirts, etc.

5. Viscose rayon is used for bed-sheets, bed-covers, home furnishings, table- cover, under wears, dresses, etc.

6. Acetate fabrics can be used for dresses, evening wears, lingerie, shirts, ties, umbrellas, rain wears, batting suits, etc.

7. Nylon is used for different types of garments e.g. under wears, night-wears, stockings, curtains, carpets, upholstery, etc.

8. Polyesters are used for varieties of dresses, bed sheets, pillow cases, home furnishings, etc.

Activities:

1. Visit a tailor’s workshop. Collect as many pieces of different kinds of fabrics as possible

2. Carry out the following tests, record your observations:

i. Appearance and Handling test

ii. Microscope test

iii. Strength test

iv. Burning test

3. Use the identified fabrics to make an album. Label specimens correctly.

Objective questions

1. Which of the following is not true:

A. Flax plant linen.

B. Sheep wool

C. Silk worm cotton

D. Silk worm silk

E. Cellulose acetate

2. Which of the following is suitable for bed linen in Nigeria?

A. Wool B. silk C. cotton D. linen E. viscose

3. Linen is suitable for A. kitchen linen B. blankets C. sweaters D. rugs E. carpets

4. Many fibres can be twisted to form A. yarn B. fabric C. cloth D. fashion E. textiles

5. Which of the following is made from petroleum? A. viscose B. nylon C. acetate D. rayon E. wool

6. One of the following will burn in flame giving a smell of burning paper

A. Cotton B. silk C. wool D. nylon E. polyester

7. Which of the following smolders when burnt and gives the smell of burning hair or feather? A. cotton and linen B. wool and silk C. nylon and silk D. nylon and cotton E. polyester and cotton.

8. The treatments given to fabrics after construction to improve their appearance are called fabric………………. A. grains B. finishes C. decorations D. neatening E. cleaning

9. Which of the following is an easy care finishing? A. luster B. sheen C. mercerization D. glazing E. drip-dry.

ASSIGNMENT

Popoola O.O. Workbook on Home Economics New Concepts for JSS Book 3 Unit 1 Page 3-5

Fabric identification methods:

Identification is the process of recognizing the different fabrics. Sometimes labels on fabrics give details of the type of fabrics and how to care for them. In some cases, the labels are not available. Also many fabrics resemble one another in appearance and feel. Thus it becomes necessary that one knows how to identify fabrics by using identification tests like the following:

The different identification tests are;

1. strength test

2. microscope test

3. burning tests

4. appearance and handling

Strength test: this is done to test both the wet and dry strength of fabrics.

Apparatus needed:

i. Two warp yarns of each fabric to be tested.

ii. A bowl of cold water.

Procedure:

i. Soak one of the yarns in a bowl of cold water.

ii. Bring it out of the water and pull with both hands.

iii. Repeat with the dry yarn. Find out if wet one is either stronger, weaker or the same as the dry one.

Microscopic test: this is a test to study the structure of the fabric under a microscope.

Apparatus needed:

i. Microscope

ii. High and low power lenses.

iii. A slide.

iv. Fabric yarns.

v. Cellotape

Procedure:

i. Mount the yarn on a slide.

ii. Examine under low power lenses. Repeat under high power lenses.

iii. Observations should centre on the shape of the fibre (flat or round) as well as markings on it.

Burning test: this is the process of holding yarns over a flame of a lighted candle, match or gas

burner.

Apparatus needed:

i. Bunsen burner stove or candle.

ii. Matches.

iii. Small pieces of different materials.

iv. A crucible.

Procedure:

i. Light the Bunsen burner, stove or candle.

ii. Hold the material or fabric over the flame and withdraw immediately.

Observations to be made are:

i. Whether the yarn

(a) burns

(b) continues to burn out the flame

(c) Shrinks form flame and melts.

(d) Melts and burns.

ii. The type of smell from the fumes.

iii. The nature of the ash.

Appearance and handling: this is the physical look and the feel of the material when touched by hand. Appearance and handling are not dependable tests, because many fabrics can have similar appearance and handling.

Identification tests of different fabrics:

1. Wool:

(a) Strength test: stronger when dry than wet

(b) Microscopic test: i. long and cylindrical appearance. ii. fibre covered with scale pointing in one direction.

(c) Burning test: i. smolders ii. Smells like burning hair or feathers. Iii. Leaves porous crushable carbon beads.

(d) Appearance and Handling: i. has lots of hair on its surface. ii. Warm and elastic quality. iii. Very little luster.

2. Silk:

(a) Strength test: weaker when wet than dry

(b) Burning test: i. smells like burning feather or hair ii. Shrivels and burns slowly

(c) Microscopic test: i. appears long, smooth and rod-like ii. Reflects light readily

(d) Appearance and Handling; i. smooth and shiny ii. Feels cool to touch

3. Cotton:

(a) Strength test; i. firm and strong when dry ii. Strong when wet

(b) Microscopic test: i. fibre has twists ii. Fibre has flat long appearance

(c) Burning test: i. burns easily, in and out of flame. ii. Smells like burning paper. iii. Leaves a grey powder.

(d) Appearance and Handling; i. smooth without luster, ii. Creases iii. cool to touch

4. Viscose Rayon;

(a) Strength test: stronger when dry than wet

(b) Microscopic test; resembles silk

(c) Burning test; i. burns readily ii. deposits white ashy spots

(d) Appearance and Handling: i. smooth ii creases badly

5. Acetate:

(a) Strength test: stronger when wet than dry

(b) Microscope test: similar to viscose rayon

(c) Burning test: i. burns slowly in and out of flame. ii. smells like acetic acid or vinegar.

6. Linen:

(a) Strength test: i. very strong naturally ii. stronger when wet than dry

(b) Microscopic test: smooth rounded appearance with nodes or swellings at regular intervals

(c) Burning test: i. burns easily in out of flame ii. leaves a feathery white ash iii. smells like burning paper.

(d) Appearance and Handling: i. cool smooth feel ii. Has luster iii. creases easily

7. Nylon:

(a) Strength test: no difference when wet or dry

(b) Microscope test: long thin fibre with clear central tube

(c) Burning test: i. shrinks from flame ii fumes smell like boiling celery iii. melts into white hard beads.

(d) Appearance and Handling: i. drapes easily ii. creases resistant iii. smooth surface

8. Polyester:

(a) Strength test: no difference

(b) Microscopic test: rod-like, smooth and cylindrical in appearance

(c) Burning test: i. melts and shrinks from flame ii. burns on in flame iii. forms hard beads

(d) Appearance and Handling: i. smooth and soft to touch ii. crease resistant

Uses of fabrics

Different fabrics are suitable for different purposes.

1. Cotton fabrics can be used for outer personal clothes, underwear, furnishings, bed sheets, pillow cases, tablecloth etc.

2. Linen can be used into different articles such as kitchen linen, like glass-cloth, tea-towels, table-covers, tray cover, serviette, suits, dresses, etc.

3. Wool can be used be used for under wears, sweaters, socks, suits, trousers, vests, baby wears, soft furniture, etc. they are particularly suitable for cold weathers and temperate countries.

4. Silk fabrics are used for making scarves, tiles, dresses, shirts, etc.

5. Viscose rayon is used for bed-sheets, bed-covers, home furnishings, table- cover, under wears, dresses, etc.

6. Acetate fabrics can be used for dresses, evening wears, lingerie, shirts, ties, umbrellas, rain wears, batting suits, etc.

7. Nylon is used for different types of garments e.g. under wears, night-wears, stockings, curtains, carpets, upholstery, etc.

8. Polyesters are used for varieties of dresses, bed sheets, pillow cases, home furnishings, etc.

Activities:

1. Visit a tailor’s workshop. Collect as many pieces of different kinds of fabrics as possible

2. Carry out the following tests, record your observations:

i. Appearance and Handling test

ii. Microscope test

iii. Strength test

iv. Burning test

3. Use the identified fabrics to make an album. Label specimens correctly.

Objective questions

1. Which of the following is not true:

A. Flax plant linen.

B. Sheep wool

C. Silk worm cotton

D. Silk worm silk

E. Cellulose acetate

2. Which of the following is suitable for bed linen in Nigeria?

A. Wool B. silk C. cotton D. linen E. viscose

3. Linen is suitable for A. kitchen linen B. blankets C. sweaters D. rugs E. carpets

4. Many fibres can be twisted to form A. yarn B. fabric C. cloth D. fashion E. textiles

5. Which of the following is made from petroleum? A. viscose B. nylon C. acetate D. rayon E. wool

6. One of the following will burn in flame giving a smell of burning paper

A. Cotton B. silk C. wool D. nylon E. polyester

7. Which of the following smolders when burnt and gives the smell of burning hair or feather? A. cotton and linen B. wool and silk C. nylon and silk D. nylon and cotton E. polyester and cotton.

8. The treatments given to fabrics after construction to improve their appearance are called fabric………………. A. grains B. finishes C. decorations D. neatening E. cleaning

9. Which of the following is an easy care finishing? A. luster B. sheen C. mercerization D. glazing E. drip-dry.

ASSIGNMENT

Popoola O.O. Workbook on Home Economics New Concepts for JSS Book 3 Unit 1 Page 3-5

Week 3

TOPIC: CARE OF DIFFERENT FABRICS

CONTENT: i. Care of different fabrics.

ii Factors to consider in laundering a fabric

Sub-Topic 1: Care of different fabrics.

Proper care, use and handling of different fabrics depend on the knowledge of their different properties or characteristics. Their ate different reasons why we should take care of our clothing.

Reasons for the care of clothing

1. To make the cloth last long.

2. To kill any disease-carrying germs in the fabric.

3. To keep the clothes looking clean or better.

4. To save money since clean clothes last long.

5. To ensure that whatever clothes you have will be available for wearing anytime.

Evaluation:

State five reasons for care of clothing

Reading Assignment:

Popoola O.O. Home Economics New Concepts for JSS Book 3 Pages 15-20

Sub-Topic 2: Factors to consider in laundering a fabric

Laundering is the process of washing and ironing clothes, sheets, etc. A laundry is a place where clothes, and sheets, etc. are washed and ironed.

i. Quantity of material to be washed: this will enable the person to assemble the required laundry agents and equipment.

ii. Water: Enough, good quality water is necessary. Soft water is best for laundry work.

iii. Weather conditions: dry weather is needed for drying the clothes. Weather conditions may not be considered when one is using a washing machine with a dryer.

iv. Space for drying clothes: wash a small quantity at a time where there is little or no space for drying.

v. Time of the day: laundry work should be carried out in the morning to allow enough time for airing and drying especially where security of materials is not guaranteed.

vi. Furnishings needed: starch, blue, etc, should be readily available if required during the laundry work.

vii. Type of fabrics to be laundered: this determines the laundry process to be used.

CONTENT: i. Care of different fabrics.

ii Factors to consider in laundering a fabric

Sub-Topic 1: Care of different fabrics.

Proper care, use and handling of different fabrics depend on the knowledge of their different properties or characteristics. Their ate different reasons why we should take care of our clothing.

Reasons for the care of clothing

1. To make the cloth last long.

2. To kill any disease-carrying germs in the fabric.

3. To keep the clothes looking clean or better.

4. To save money since clean clothes last long.

5. To ensure that whatever clothes you have will be available for wearing anytime.

Evaluation:

State five reasons for care of clothing

Reading Assignment:

Popoola O.O. Home Economics New Concepts for JSS Book 3 Pages 15-20

Sub-Topic 2: Factors to consider in laundering a fabric

Laundering is the process of washing and ironing clothes, sheets, etc. A laundry is a place where clothes, and sheets, etc. are washed and ironed.

i. Quantity of material to be washed: this will enable the person to assemble the required laundry agents and equipment.

ii. Water: Enough, good quality water is necessary. Soft water is best for laundry work.

iii. Weather conditions: dry weather is needed for drying the clothes. Weather conditions may not be considered when one is using a washing machine with a dryer.

iv. Space for drying clothes: wash a small quantity at a time where there is little or no space for drying.

v. Time of the day: laundry work should be carried out in the morning to allow enough time for airing and drying especially where security of materials is not guaranteed.

vi. Furnishings needed: starch, blue, etc, should be readily available if required during the laundry work.

vii. Type of fabrics to be laundered: this determines the laundry process to be used.

Week 4

TOPIC: CARE OF DIFFERENT FABRICS

CONTENT: i. laundry agents and equipment

ii. Laundry processes

Sub-Topic 1: LAUNDRY AGENTS AND EQUIPMENT

LAUNDRY AGENTS AND EQUIPMENT

Laundry agents are substances with cleansing properties for washing clothes.

1. Water: this is a very important cleaning agent in laundry

Uses:

i. Water is used for soaking clothes and household articles before washing.

ii. It cleanses articles with non-greasy dirt to a certain extent. For instance, sugar dissolves in water.

iii. Hot water will melt and soften grease.

iv. It is used for rinsing washed articles.

v. It is used to dampen articles before ironing.

2. Detergents: a detergent is any substance that cleanses or aids the removal of dirt. soaps and synthetic/soapless detergents are all detergents. soap is made by the reaction between fats/oil of animal/vegetable origin, and alkalis. Synthetic detergents are made from mineral oil or petroleum products.

Uses:

i. Detergents are used to lower the surface tension of water.

ii. Enable the water to wet the dirty articles/fabrics.

iii. Break up grease-held dirt in the fabric into tiny particles.

iv. Remove dirt from the fabric.

3. Bleaches:

Uses:

i. Make white cotton and linen fabrics whiter.

ii. Remove certain stains.

iii. Kill disease carrying germs in fabrics.

4. Stiffening agents: these include different types of laundry starch, as, hot water starch, cool water starch, spray or aerosol starches, gum Arabic, glue.

Uses:

i. To stiffen cotton and linen fabrics.

ii. To give the fabrics a smooth surface.

iii. To give the fabrics a fresh look.

iv. To make fabrics keep clean for longer period.

Note: A starch article keeps clean longer than unstarched articles. This is because dirt cannot adhere easily to the smooth surface.

5. Stain removers: a stain is a spot or a mark made on a fabric which gives a colour that is different from the rest of the surface of the fabric. There are different types of stains e.g. vegetable, animal and grease stains. Each type of stain requires a specific remover, as follows:

Stains removers stains

i. Methylated spirit greasy stains lipstick

ii. Lemon juice iron mould (rust), ink

iii. Bleach mildew

iv. Kerosene palm oil, tar

v. Turpentine shoe polsh

vi. Ammonia perspiration

vii. Celycerine chocolate, coffee, tea

viii. Enzyme detergent blood

6. Laundry blue: this is used during the last rinse to improve the appearance of faded white material or materials with a blue background.

Laundry Equipment:

Laundry equipment is classified into groups:

1. Equipment for washing: these include:

i. Galvanized or plastic buckets and basins.

ii. Laundry sinks or tubes.

iii. Washing machines.

iv. Laundry brushes

2. Equipment for boiling:

i. Stainless steel pots.

ii. Tongs for turning clothes while boiling.

3. Equipment for drying:

i. Wooden or plastic pegs.

ii. Clothes lines.

iii. Hangers both for indoors and outdoors.

4. Equipment for finishing:

i. Press irons e.g. box and flat, electric and steam irons.

ii. Ironing boards.

iii. Ironing pads

Evaluation:

1. Give five factors to consider when laundering clothes

2. i. define the term laundering.

iii. List four laundry agents and their uses.

iv. State three laundry agents and uses.

v. State three pieces of laundry equipment.

Sub-Topic ii: Laundry processes.

Laundry processes are the steps to be followed when laundering personal or family clothes. They include the following:

1. Sorting: this is grouping the materials according to

a. Colour

b. Types e.g. cotton, wool, polyester etc.

c. Degree of dirt, and highly soiled fabrics.

d. Colour-fast and non-colour fasts.

2. Mending: this is sewing or stitching split seams or tears and fastening loose buttons and hooks before washing.

3. Stain removal: removal all stains accordingly before washing.

4. Soak or steeping: this is leaving the materials in water for some time to loosen surface dirt.

5. Washing: washing is removing dirt from clothes with the aid of water and soap using any of the following methods:

a. Washing by rubbing

b. Washing by kneading and squeezing

c. Washing by squeezing alone

d. Using a washing machine if available.

6. Boiling: is used when necessary. It helps to whiten and disinfect clothes. Cotton and linen materials could be boiled e.g. babies’ napkins, handkerchiefs, white bed sheets, etc.

7. Rinsing: rinsing is the process by which dirty lather is washed off the clothes.

8. Blueing and stiffening: blue or stiffening agent could be added to the rinsed clothes if desired.

9. Drying: drying is the complete removal of water from rinsed clothes. It could be by:

i. Exposure to sunshine

ii. Exposure under a shady but breezy place.

iii. Using an electric dryer.

10. Ironing: ironing is pressing dried clothes with a hot iron in order to regain their original appearance. for best results, clothes should be ironed while slightly damp or if they are very dry.

11. Airing: airing is hanging out ironed clothes in the open for a short time before storage. it helps to dry out the steam left in between the threads of the clothes after ironing.

12. Folding and storage: aired clothes could be:

a. Folded and stored in a box or drawers

b. By hanging in a wardrobe.

[youtube]https://www.youtube.com/watch?v=CK6AXpyMiwA[/youtube]

Objective Test:

1. This can damage fabrics (a) ironing (b) water (c) dirt (d) starch (e) soap

2. Substances which aid the removal of dirt from fabric articles are called laundry (a) agents (b) agencies (c) troughs (d) buckets (e) supports

3. Which of the following is correct for ironing linen and cotton?

(a) Very hot iron (b) hot iron (c) moderately hot iron (d) cool iron (e) medium iron

4. Wool should be washed with……………water

(a) Boiling (b) very hot (c) hot (d) warm (e) cold

5. Prolonged exposure of wool to direct heat or sunlight

(a) Strengthens it (b) brightens it (c) protects it (d) saves it (e) destroys it.

CONTENT: i. laundry agents and equipment

ii. Laundry processes

Sub-Topic 1: LAUNDRY AGENTS AND EQUIPMENT

LAUNDRY AGENTS AND EQUIPMENT

Laundry agents are substances with cleansing properties for washing clothes.

1. Water: this is a very important cleaning agent in laundry

Uses:

i. Water is used for soaking clothes and household articles before washing.

ii. It cleanses articles with non-greasy dirt to a certain extent. For instance, sugar dissolves in water.

iii. Hot water will melt and soften grease.

iv. It is used for rinsing washed articles.

v. It is used to dampen articles before ironing.

2. Detergents: a detergent is any substance that cleanses or aids the removal of dirt. soaps and synthetic/soapless detergents are all detergents. soap is made by the reaction between fats/oil of animal/vegetable origin, and alkalis. Synthetic detergents are made from mineral oil or petroleum products.

Uses:

i. Detergents are used to lower the surface tension of water.

ii. Enable the water to wet the dirty articles/fabrics.

iii. Break up grease-held dirt in the fabric into tiny particles.

iv. Remove dirt from the fabric.

3. Bleaches:

Uses:

i. Make white cotton and linen fabrics whiter.

ii. Remove certain stains.

iii. Kill disease carrying germs in fabrics.

4. Stiffening agents: these include different types of laundry starch, as, hot water starch, cool water starch, spray or aerosol starches, gum Arabic, glue.

Uses:

i. To stiffen cotton and linen fabrics.

ii. To give the fabrics a smooth surface.

iii. To give the fabrics a fresh look.

iv. To make fabrics keep clean for longer period.

Note: A starch article keeps clean longer than unstarched articles. This is because dirt cannot adhere easily to the smooth surface.

5. Stain removers: a stain is a spot or a mark made on a fabric which gives a colour that is different from the rest of the surface of the fabric. There are different types of stains e.g. vegetable, animal and grease stains. Each type of stain requires a specific remover, as follows:

Stains removers stains

i. Methylated spirit greasy stains lipstick

ii. Lemon juice iron mould (rust), ink

iii. Bleach mildew

iv. Kerosene palm oil, tar

v. Turpentine shoe polsh

vi. Ammonia perspiration

vii. Celycerine chocolate, coffee, tea

viii. Enzyme detergent blood

6. Laundry blue: this is used during the last rinse to improve the appearance of faded white material or materials with a blue background.

Laundry Equipment:

Laundry equipment is classified into groups:

1. Equipment for washing: these include:

i. Galvanized or plastic buckets and basins.

ii. Laundry sinks or tubes.

iii. Washing machines.

iv. Laundry brushes

2. Equipment for boiling:

i. Stainless steel pots.

ii. Tongs for turning clothes while boiling.

3. Equipment for drying:

i. Wooden or plastic pegs.

ii. Clothes lines.

iii. Hangers both for indoors and outdoors.

4. Equipment for finishing:

i. Press irons e.g. box and flat, electric and steam irons.

ii. Ironing boards.

iii. Ironing pads

Evaluation:

1. Give five factors to consider when laundering clothes

2. i. define the term laundering.

iii. List four laundry agents and their uses.

iv. State three laundry agents and uses.

v. State three pieces of laundry equipment.

Sub-Topic ii: Laundry processes.

Laundry processes are the steps to be followed when laundering personal or family clothes. They include the following:

1. Sorting: this is grouping the materials according to

a. Colour

b. Types e.g. cotton, wool, polyester etc.

c. Degree of dirt, and highly soiled fabrics.

d. Colour-fast and non-colour fasts.

2. Mending: this is sewing or stitching split seams or tears and fastening loose buttons and hooks before washing.

3. Stain removal: removal all stains accordingly before washing.

4. Soak or steeping: this is leaving the materials in water for some time to loosen surface dirt.

5. Washing: washing is removing dirt from clothes with the aid of water and soap using any of the following methods:

a. Washing by rubbing

b. Washing by kneading and squeezing

c. Washing by squeezing alone

d. Using a washing machine if available.

6. Boiling: is used when necessary. It helps to whiten and disinfect clothes. Cotton and linen materials could be boiled e.g. babies’ napkins, handkerchiefs, white bed sheets, etc.

7. Rinsing: rinsing is the process by which dirty lather is washed off the clothes.

8. Blueing and stiffening: blue or stiffening agent could be added to the rinsed clothes if desired.

9. Drying: drying is the complete removal of water from rinsed clothes. It could be by:

i. Exposure to sunshine

ii. Exposure under a shady but breezy place.

iii. Using an electric dryer.

10. Ironing: ironing is pressing dried clothes with a hot iron in order to regain their original appearance. for best results, clothes should be ironed while slightly damp or if they are very dry.

11. Airing: airing is hanging out ironed clothes in the open for a short time before storage. it helps to dry out the steam left in between the threads of the clothes after ironing.

12. Folding and storage: aired clothes could be:

a. Folded and stored in a box or drawers

b. By hanging in a wardrobe.

[youtube]https://www.youtube.com/watch?v=CK6AXpyMiwA[/youtube]

Objective Test:

1. This can damage fabrics (a) ironing (b) water (c) dirt (d) starch (e) soap

2. Substances which aid the removal of dirt from fabric articles are called laundry (a) agents (b) agencies (c) troughs (d) buckets (e) supports

3. Which of the following is correct for ironing linen and cotton?

(a) Very hot iron (b) hot iron (c) moderately hot iron (d) cool iron (e) medium iron

4. Wool should be washed with……………water

(a) Boiling (b) very hot (c) hot (d) warm (e) cold

5. Prolonged exposure of wool to direct heat or sunlight

(a) Strengthens it (b) brightens it (c) protects it (d) saves it (e) destroys it.

Week 5

TOPIC: BASIC ELEMENTS IN DESIGN

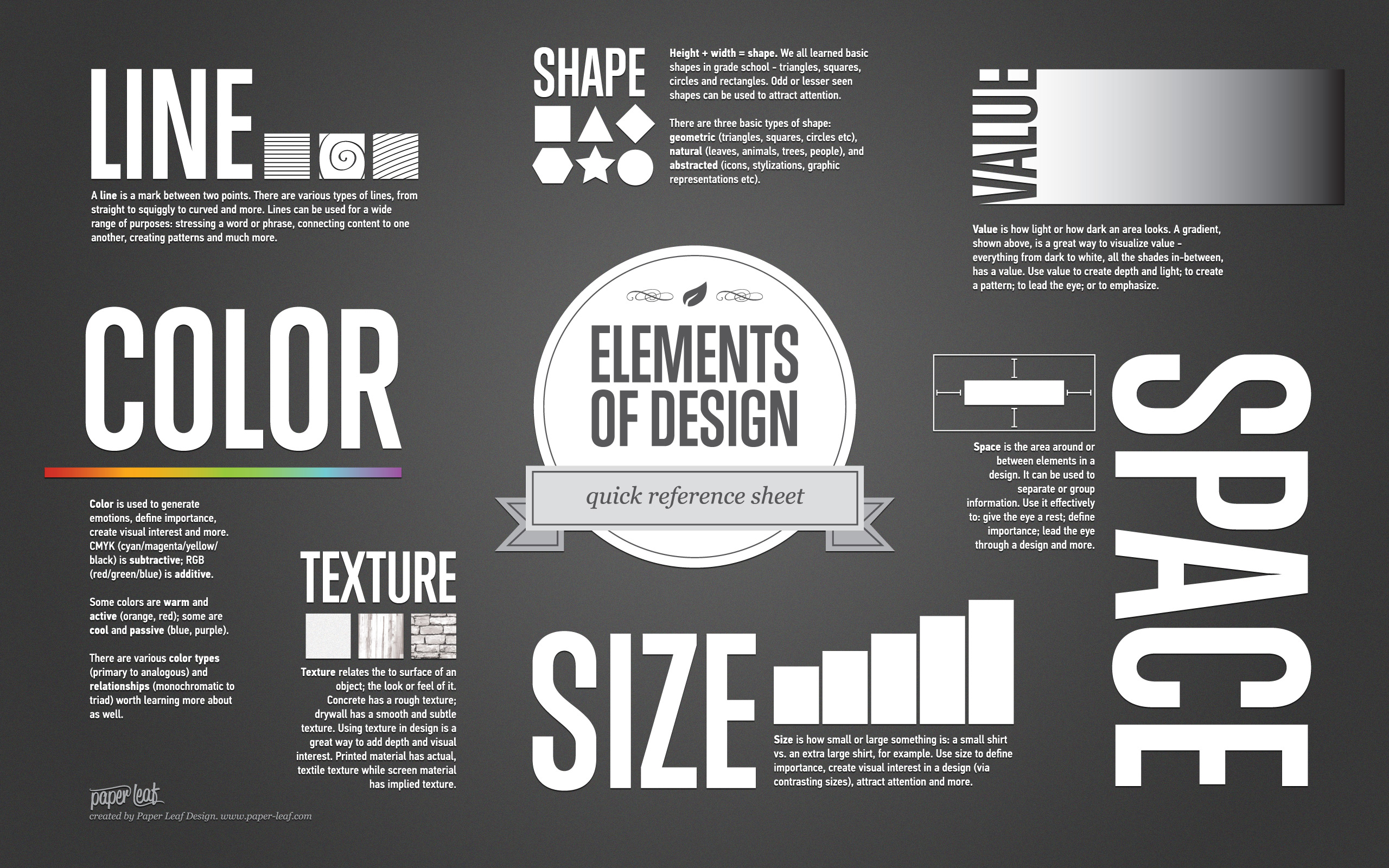

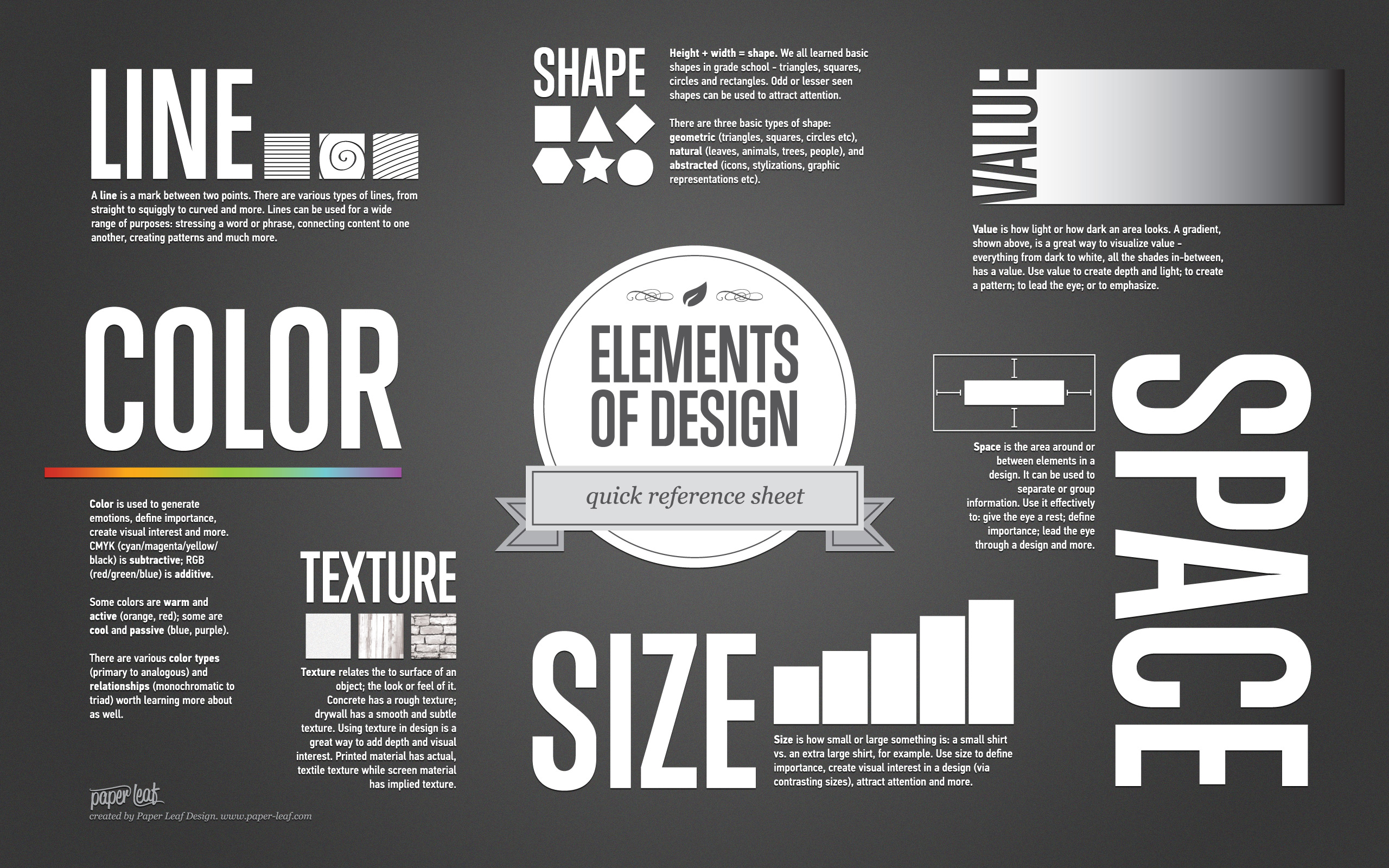

Content: 1. Basic element in design, color wheel and harmony.

2. Making patterns using lines.

A good understanding of the basic elements of designs in clothing decisions is very essential as they affect the way you appear to yourself and others when you dress up.

Sub –Topic 1: Basic element in design, color wheel and harmony.

They basic elements of design are

(1) Line: This refers to the outline of an object or to obvious lines within it

(2) Shape: This refers to the form of a solid object which is created when lines are combined. The outline of a garment is its shape

(3) Space: This refers to the three dimensional area that is to be designed.

It is the entire area within a garment. Garment lines break up this total space .pockets seam buttons and trim divide a garment into different shapes

(4) Texture: This is the way the surface of a fabric looks and feels

(5) Color: This is one of the most important elements.

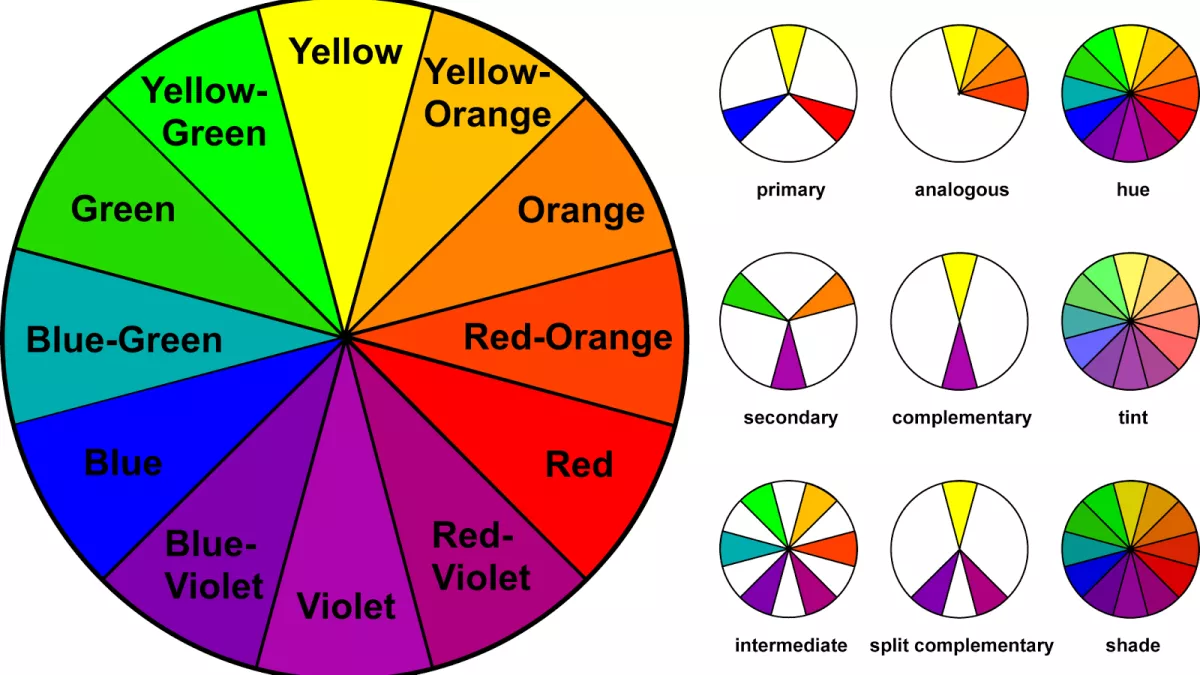

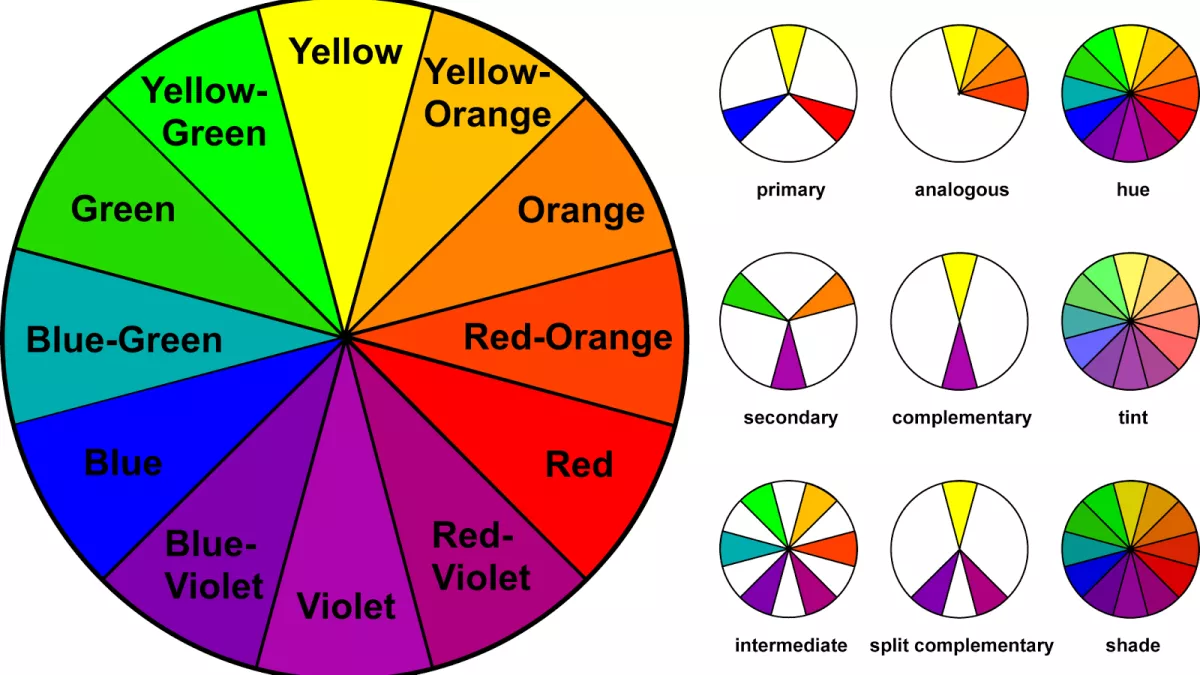

COLOUR WHEEL.

This is an arrangement of colours in a circle, like the face of a round clock, to show how they are related.

(1) THE PRIMARY COLOURS: Red, yellow and blue.

(2) THE SECONDARY COLOURS: Orange, green and purple or violet.

(3)TERTIARY OR INTERMEDIATE COLOURS: These are six. And each is a blend of the primary and secondary colours. They include Red violet, Blue violet, Blue green, Yellow green, Yellow orange, and Red orange

(4)WARM COLOURS: These are red yellow orange, yellow _orange, red orange e.t.c.

(5)COOL COLOURS: These are blue green purple, blue –purple, blue-green e.t.c.

Colour wheel.

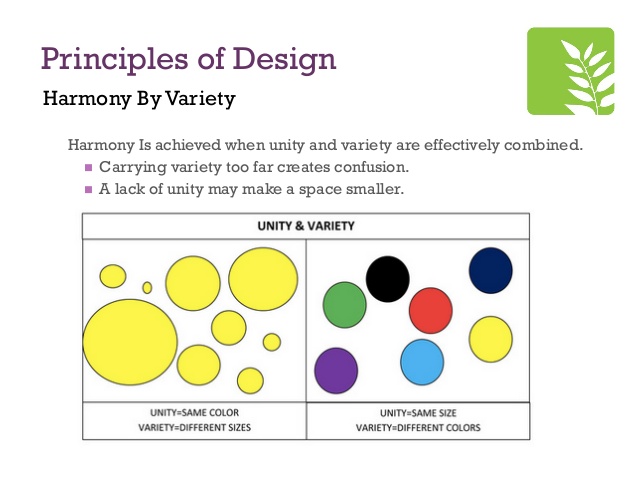

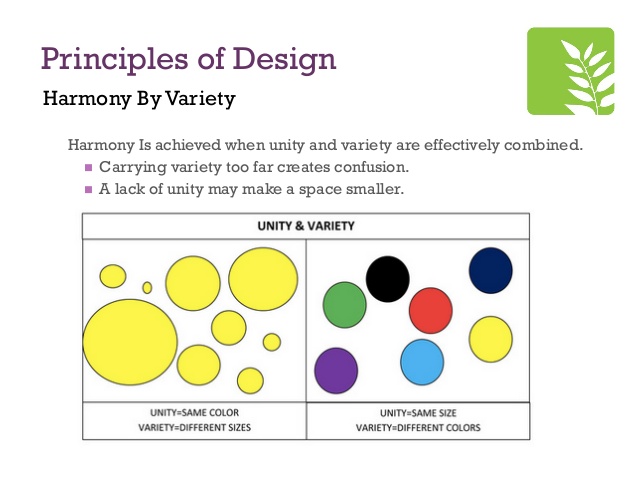

HARMONY: This is an effect achieved when all the parts of the garment blend together to produce a pleasing effect.

MAKING PATTERNS USING LINES

Line is another element in design. There are different types of lines and each has different types of effects on the figure.

These lines include;

(A) VERTICAL LINES;

These can add height .They make a short and stout person appear slimmer and taller.

(b) HORIZONTAL LINES

These tend to add to the appearance of width and reduce height

(C) DIAGONAL LINES

These should appear from left to right when looking at a garment. They take the eye downward in a slimming line.

(D) CURVED LINES

These create soft lines, that are usually flattering.

EVALUATION:

1. List the primary, secondary, and tertiary colours .

2. Draw a colour wheel.

3. State three types of lines in clothing designs.

4. Use the three types of lines to draw three different designs.

Objective Test:

1 ……..refers to the outline of an object

A Shape

B Proportion

C Line

D Texture

E Form

2. ________ refers to the form of a solid object.

(a) Texture (b) Feeling (c) Form (d) Proportion (e) Shape

3. The three- dimensional area that is to be designed is_________.

(a) texture (b) shape (c) size (d) space (e) proportion

4. The way the surface of a fabric looks and feels is

(a) colour (b) filling (c) shape (d) space (e) texture

5. ¬_______ is the lightness or darkness of a colour.

(a) Hue (b) Value (c) Tint (d) Harmony (e) Intensity

6. Red, Yellow and Blue are _______ colours.

(a) Primary (b) secondary (c) tertiary (d) lower (e) no option

7. Which of these lines add heights (a) Vertical (b) horizontal (c) diagonal (d) curved (e) wide

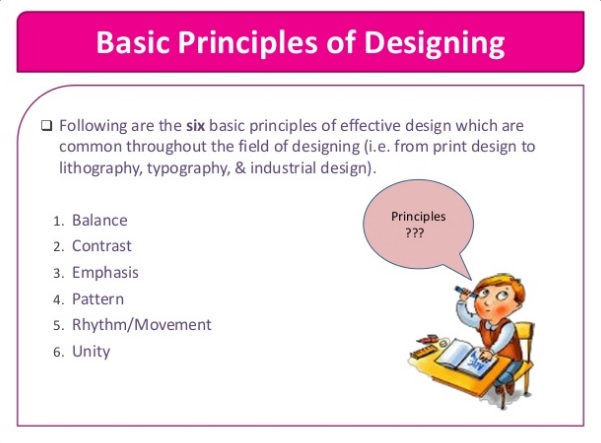

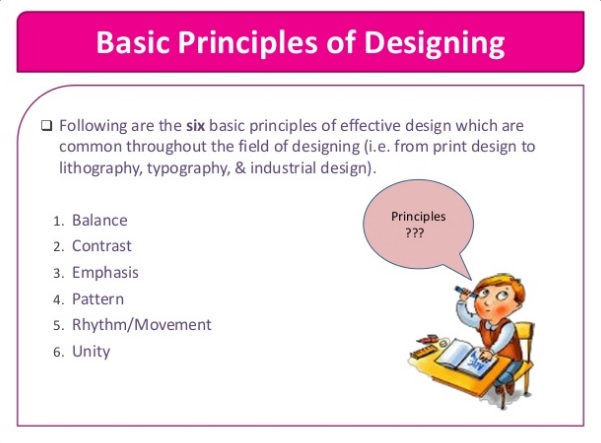

8. Which of these are principles of design?

(a) Proportion, balance and emphasis

(b) Proportion, colour and line

(c) Colour, line and balance

(d) Emphasis, proportion and colour

(e) Shape, line and form

9. White colour symbolizes ________. (a) peace (b) harmony (c) restlessness (d) turmoil (e) love

10. Black colour usually symbolizes ______.

(a) Mourning (b) Joy (c) Dancing (d) Favour (e) Good luck

Content: 1. Basic element in design, color wheel and harmony.

2. Making patterns using lines.

A good understanding of the basic elements of designs in clothing decisions is very essential as they affect the way you appear to yourself and others when you dress up.

Sub –Topic 1: Basic element in design, color wheel and harmony.

They basic elements of design are

(1) Line: This refers to the outline of an object or to obvious lines within it

(2) Shape: This refers to the form of a solid object which is created when lines are combined. The outline of a garment is its shape

(3) Space: This refers to the three dimensional area that is to be designed.

It is the entire area within a garment. Garment lines break up this total space .pockets seam buttons and trim divide a garment into different shapes

(4) Texture: This is the way the surface of a fabric looks and feels

(5) Color: This is one of the most important elements.

COLOUR WHEEL.

This is an arrangement of colours in a circle, like the face of a round clock, to show how they are related.

(1) THE PRIMARY COLOURS: Red, yellow and blue.

(2) THE SECONDARY COLOURS: Orange, green and purple or violet.

(3)TERTIARY OR INTERMEDIATE COLOURS: These are six. And each is a blend of the primary and secondary colours. They include Red violet, Blue violet, Blue green, Yellow green, Yellow orange, and Red orange

(4)WARM COLOURS: These are red yellow orange, yellow _orange, red orange e.t.c.

(5)COOL COLOURS: These are blue green purple, blue –purple, blue-green e.t.c.

Colour wheel.

HARMONY: This is an effect achieved when all the parts of the garment blend together to produce a pleasing effect.

MAKING PATTERNS USING LINES

Line is another element in design. There are different types of lines and each has different types of effects on the figure.

These lines include;

(A) VERTICAL LINES;

These can add height .They make a short and stout person appear slimmer and taller.

(b) HORIZONTAL LINES

These tend to add to the appearance of width and reduce height

(C) DIAGONAL LINES

These should appear from left to right when looking at a garment. They take the eye downward in a slimming line.

(D) CURVED LINES

These create soft lines, that are usually flattering.

EVALUATION:

1. List the primary, secondary, and tertiary colours .

2. Draw a colour wheel.

3. State three types of lines in clothing designs.

4. Use the three types of lines to draw three different designs.

Objective Test:

1 ……..refers to the outline of an object

A Shape

B Proportion

C Line

D Texture

E Form

2. ________ refers to the form of a solid object.

(a) Texture (b) Feeling (c) Form (d) Proportion (e) Shape

3. The three- dimensional area that is to be designed is_________.

(a) texture (b) shape (c) size (d) space (e) proportion

4. The way the surface of a fabric looks and feels is

(a) colour (b) filling (c) shape (d) space (e) texture

5. ¬_______ is the lightness or darkness of a colour.

(a) Hue (b) Value (c) Tint (d) Harmony (e) Intensity

6. Red, Yellow and Blue are _______ colours.

(a) Primary (b) secondary (c) tertiary (d) lower (e) no option

7. Which of these lines add heights (a) Vertical (b) horizontal (c) diagonal (d) curved (e) wide

8. Which of these are principles of design?

(a) Proportion, balance and emphasis

(b) Proportion, colour and line

(c) Colour, line and balance

(d) Emphasis, proportion and colour

(e) Shape, line and form

9. White colour symbolizes ________. (a) peace (b) harmony (c) restlessness (d) turmoil (e) love

10. Black colour usually symbolizes ______.

(a) Mourning (b) Joy (c) Dancing (d) Favour (e) Good luck

Week 7

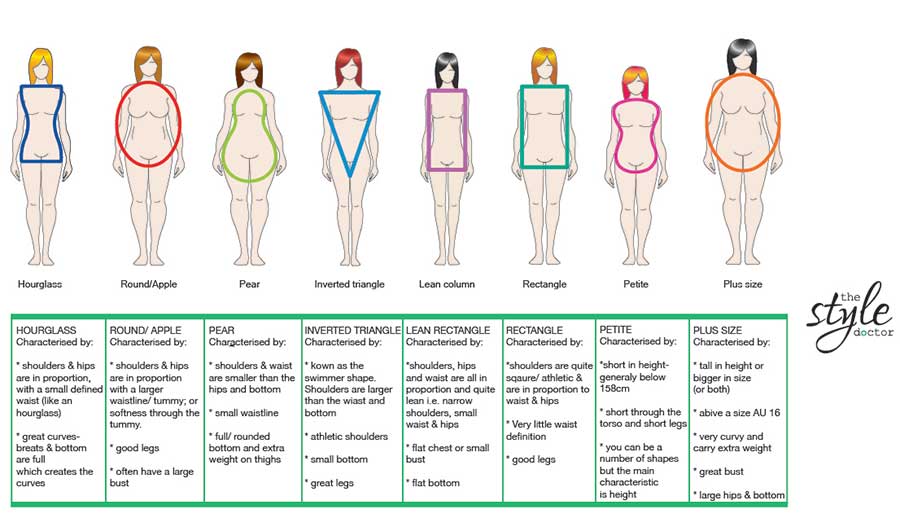

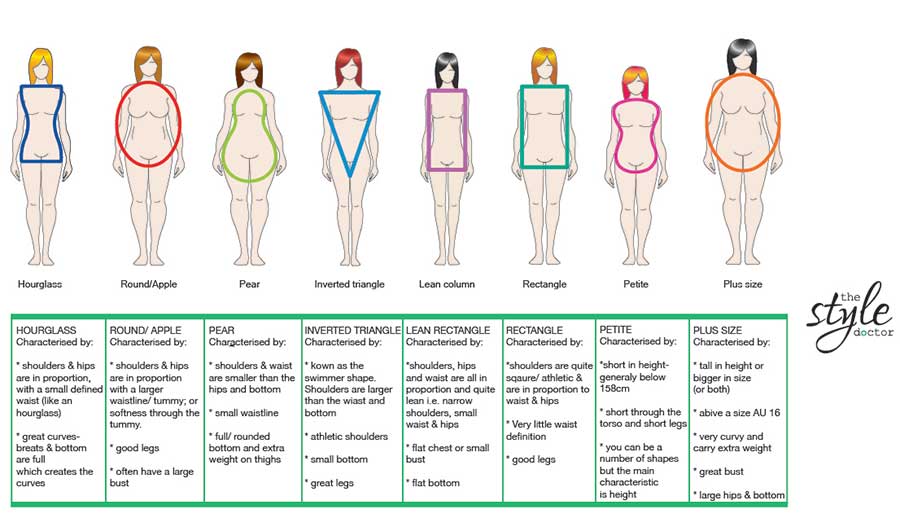

TOPIC: FIGURE TYPES

CONTENT: 1. Different figure types, figure problems or faults

2. Ways of solving figure problems or faults

SUB-TOPIC 1: DIFFERENT FIGURE TYPES, FIGURE PROBLEMS OR FAULTS.

The dress you wear tells people a lot about the type of person you are. It also gives you self confidence. You will also be addressed the way you dress well.

Figure in clothing construction means the body outline or shape of a person. No two persons are exactly alike. Therefore, different people have different figure types. There are also figure faults or problems. These faults can be concealed with suitable styles, colours and patterns of clothes.

There are nine (9) basic figure types, which are based on two measurements.

i. Heights

ii. Nape to waist

Figure Types

1. Girls

2. Chubby

3. Young/ Juniors/Teen

4. Junior Petite

5. Junior

6. Miss petite

7. Misses

8. Half size

9. Women

COMMON FIGURE FAULTS OR PROBLEMS:

Styles of dresses which look beautiful on one person may be ugly on another. This is because people have different figure faults, such as:

1. Very long/Very short Necks

2. Big burst or Flat chest

3. Very short or Very tall figure

4. Tall and Thin

5. Tall and Heavy

6. Short and Slender

7. Short and Plump

8. Heavy Hip

9. Small Burst

10. Short waist

11. Long waist

12. Narrow shoulder

13. Prominent Abdomen

In each case a person can choose those styles, patterns or designs and colours that help to enhance her good features and hide the defects(i.e. Problems)

EVALUATION:

1. Enumerate 5 figure faults that you have learnt.

2. Outline briefly how your dressing speaks about your personality.

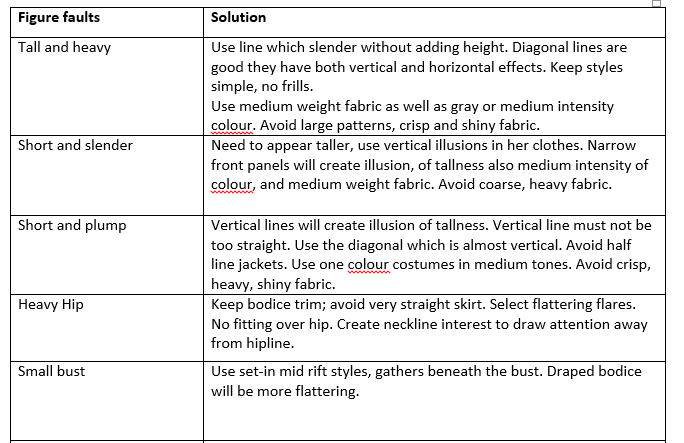

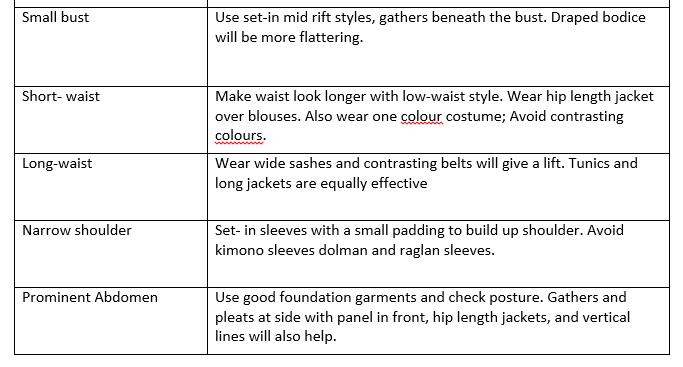

SUB – TOPIC 2: WAYS OF SOLVING FIGURE PROBLEMS OR FAULTS.

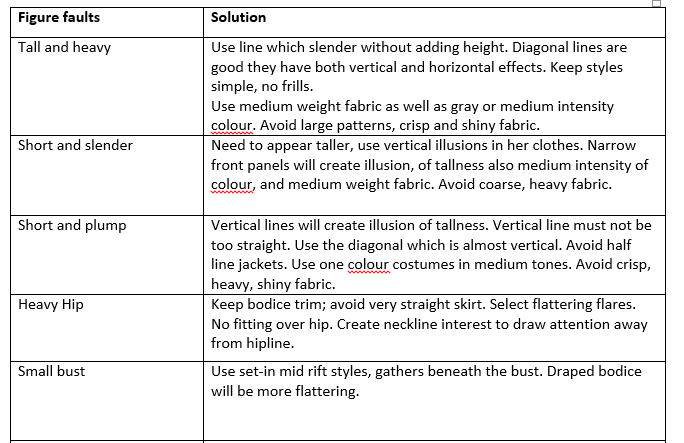

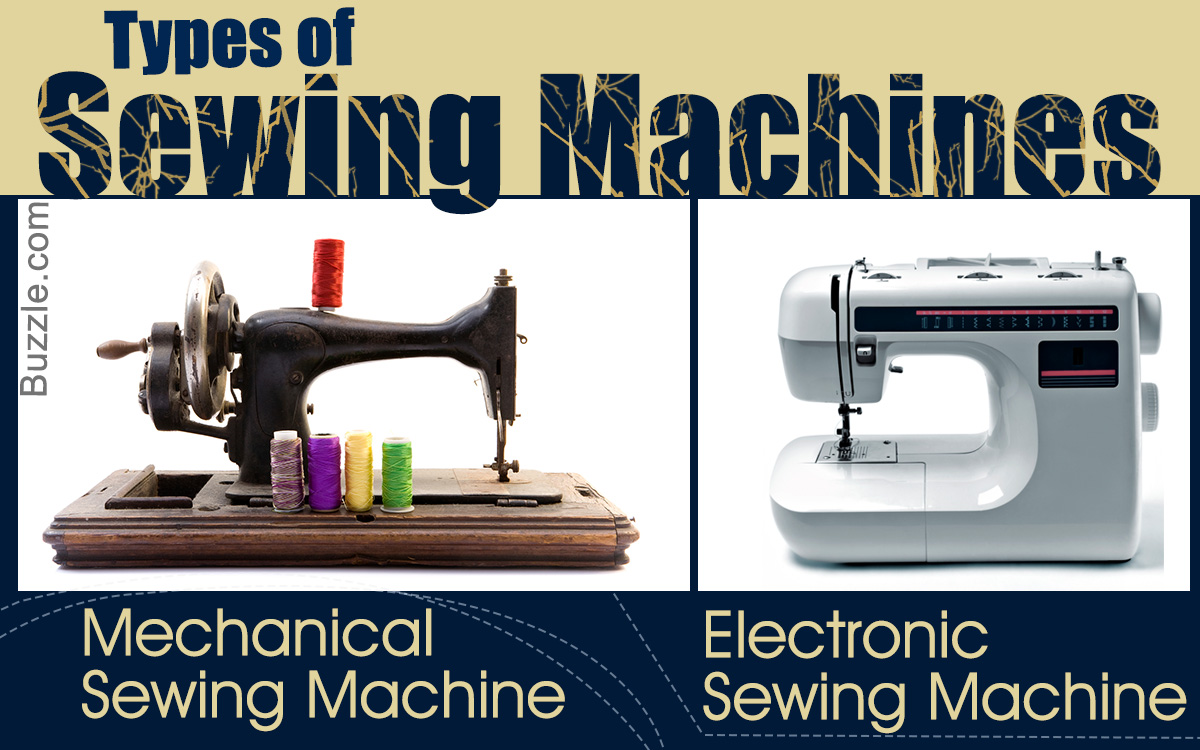

Figure faults Solution

Tall and heavy - Use line which slender without adding height. Diagonal lines are good they have both vertical and horizontal effects. Keep styles simple, no frills.

Use medium weight fabric as well as gray or medium intensity colour. Avoid large patterns, crisp and shiny fabric.

Short and slender - Need to appear taller, use vertical illusions in her clothes. Narrow front panels will create illusion, of tallness also medium intensity of colour, and medium weight fabric. Avoid coarse, heavy fabric.

Short and plump - Vertical lines will create illusion of tallness. Vertical line must not be too straight. Use the diagonal which is almost vertical. Avoid half line jackets. Use one colour costumes in medium tones. Avoid crisp, heavy, shiny fabric.

Heavy Hip - Keep bodice trim; avoid very straight skirt. Select flattering flares. No fitting over hip. Create neckline interest to draw attention away from hipline.

Small bust - Use set-in mid rift styles, gathers beneath the bust. Draped bodice will be more flattering.

Short- waist - Make waist look longer with low-waist style. Wear hip length jacket over blouses. Also wear one colour costume; Avoid contrasting colours.

Long-waist - Wear wide sashes and contrasting belts will give a lift. Tunics and long jackets are equally effective

Narrow shoulder - Set- in sleeves with a small padding to build up shoulder. Avoid kimono sleeves dolman and raglan sleeves.

Prominent Abdomen - Use good foundation garments and check posture. Gathers and pleats at side with panel in front, hip length jackets, and vertical lines will also help.

EVALUATION:

1. State any three styles that are suitable for ;

i. A tall and slender figure.

ii. A short and plump figure.

2. State any three styles that are not suitable for:

i. A figure with large bust.

ii. A figure with large hips.

ASSIGNMENT:

1. Those additional things we wear in order to supplement our clothes are called----- (a) dresses (b) garments (c) accessories (d) pins (e) scarves.

2. The body outline or shape of a person is her ----- (a) body (b) figure (c) style (d) dress (e) outfit.

3. Different people have ----- (a) the same figure (b) similar figures (c) one figure (d) different figure (e) like figures.

4. Dark and cool colours make a person look ----- (a) bigger (b) fatter(c) smaller (d) heavy (e) happy.

5. Warm and light colours make a person ------- (a) smaller (b) unhappy (c) happy (d) warm (e) bigger.

6. Slim figures look fuller in------ (a) dark colours (b) cool colours (c) light colours (d) black (e) brown.

7. Which of the following make a short person appear taller?(a) horizontal lines (b) vertical lines (c) diagonal lines (d)curved lines (e)all of the above.

8. Fat people should avoid ----- (a) vertical lines (b) horizontal lines (c) cool colours (d) dark colour (e)tiny patterns.

9. Figure faults includes the following ,except……………..(a) big bust (b) flat hip (c) broad shoulders (d) flat nose

10. Someone with large or big bust should wear all except ………((A)open collars (B)straight lapel (C)very high neckline (D)vertical lines (E)tailor straight bodice.

CONTENT: 1. Different figure types, figure problems or faults

2. Ways of solving figure problems or faults

SUB-TOPIC 1: DIFFERENT FIGURE TYPES, FIGURE PROBLEMS OR FAULTS.

The dress you wear tells people a lot about the type of person you are. It also gives you self confidence. You will also be addressed the way you dress well.

Figure in clothing construction means the body outline or shape of a person. No two persons are exactly alike. Therefore, different people have different figure types. There are also figure faults or problems. These faults can be concealed with suitable styles, colours and patterns of clothes.

There are nine (9) basic figure types, which are based on two measurements.

i. Heights

ii. Nape to waist

Figure Types

1. Girls

2. Chubby

3. Young/ Juniors/Teen

4. Junior Petite

5. Junior

6. Miss petite

7. Misses

8. Half size

9. Women

COMMON FIGURE FAULTS OR PROBLEMS:

Styles of dresses which look beautiful on one person may be ugly on another. This is because people have different figure faults, such as:

1. Very long/Very short Necks

2. Big burst or Flat chest

3. Very short or Very tall figure

4. Tall and Thin

5. Tall and Heavy

6. Short and Slender

7. Short and Plump

8. Heavy Hip

9. Small Burst

10. Short waist

11. Long waist

12. Narrow shoulder

13. Prominent Abdomen

In each case a person can choose those styles, patterns or designs and colours that help to enhance her good features and hide the defects(i.e. Problems)

EVALUATION:

1. Enumerate 5 figure faults that you have learnt.

2. Outline briefly how your dressing speaks about your personality.

SUB – TOPIC 2: WAYS OF SOLVING FIGURE PROBLEMS OR FAULTS.

Figure faults Solution

Tall and heavy - Use line which slender without adding height. Diagonal lines are good they have both vertical and horizontal effects. Keep styles simple, no frills.

Use medium weight fabric as well as gray or medium intensity colour. Avoid large patterns, crisp and shiny fabric.

Short and slender - Need to appear taller, use vertical illusions in her clothes. Narrow front panels will create illusion, of tallness also medium intensity of colour, and medium weight fabric. Avoid coarse, heavy fabric.

Short and plump - Vertical lines will create illusion of tallness. Vertical line must not be too straight. Use the diagonal which is almost vertical. Avoid half line jackets. Use one colour costumes in medium tones. Avoid crisp, heavy, shiny fabric.

Heavy Hip - Keep bodice trim; avoid very straight skirt. Select flattering flares. No fitting over hip. Create neckline interest to draw attention away from hipline.

Small bust - Use set-in mid rift styles, gathers beneath the bust. Draped bodice will be more flattering.

Short- waist - Make waist look longer with low-waist style. Wear hip length jacket over blouses. Also wear one colour costume; Avoid contrasting colours.

Long-waist - Wear wide sashes and contrasting belts will give a lift. Tunics and long jackets are equally effective

Narrow shoulder - Set- in sleeves with a small padding to build up shoulder. Avoid kimono sleeves dolman and raglan sleeves.

Prominent Abdomen - Use good foundation garments and check posture. Gathers and pleats at side with panel in front, hip length jackets, and vertical lines will also help.

EVALUATION:

1. State any three styles that are suitable for ;

i. A tall and slender figure.

ii. A short and plump figure.

2. State any three styles that are not suitable for:

i. A figure with large bust.

ii. A figure with large hips.

ASSIGNMENT:

1. Those additional things we wear in order to supplement our clothes are called----- (a) dresses (b) garments (c) accessories (d) pins (e) scarves.

2. The body outline or shape of a person is her ----- (a) body (b) figure (c) style (d) dress (e) outfit.

3. Different people have ----- (a) the same figure (b) similar figures (c) one figure (d) different figure (e) like figures.

4. Dark and cool colours make a person look ----- (a) bigger (b) fatter(c) smaller (d) heavy (e) happy.

5. Warm and light colours make a person ------- (a) smaller (b) unhappy (c) happy (d) warm (e) bigger.

6. Slim figures look fuller in------ (a) dark colours (b) cool colours (c) light colours (d) black (e) brown.

7. Which of the following make a short person appear taller?(a) horizontal lines (b) vertical lines (c) diagonal lines (d)curved lines (e)all of the above.

8. Fat people should avoid ----- (a) vertical lines (b) horizontal lines (c) cool colours (d) dark colour (e)tiny patterns.

9. Figure faults includes the following ,except……………..(a) big bust (b) flat hip (c) broad shoulders (d) flat nose

10. Someone with large or big bust should wear all except ………((A)open collars (B)straight lapel (C)very high neckline (D)vertical lines (E)tailor straight bodice.

Week 8

TOPIC: THE SEWING MACHINE

CONTENT 1: Types of Sewing Machine and Different Parts of Sewing Machines and Their Functions.

2. Guidelines for choosing a Sewing Machine

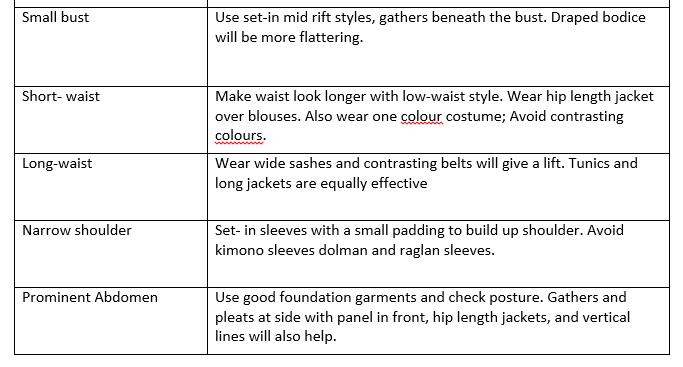

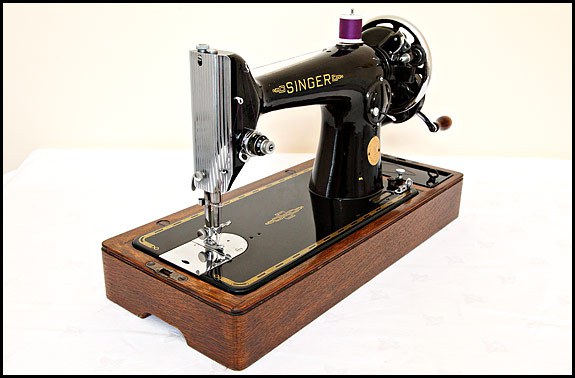

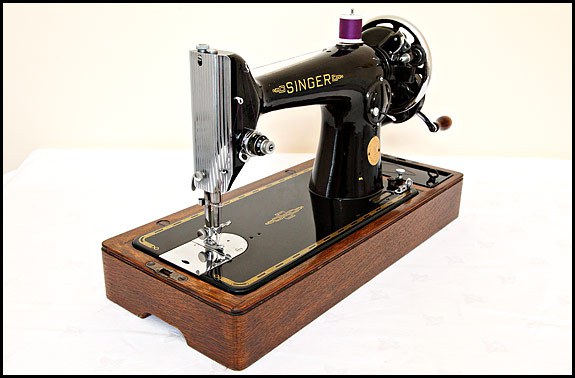

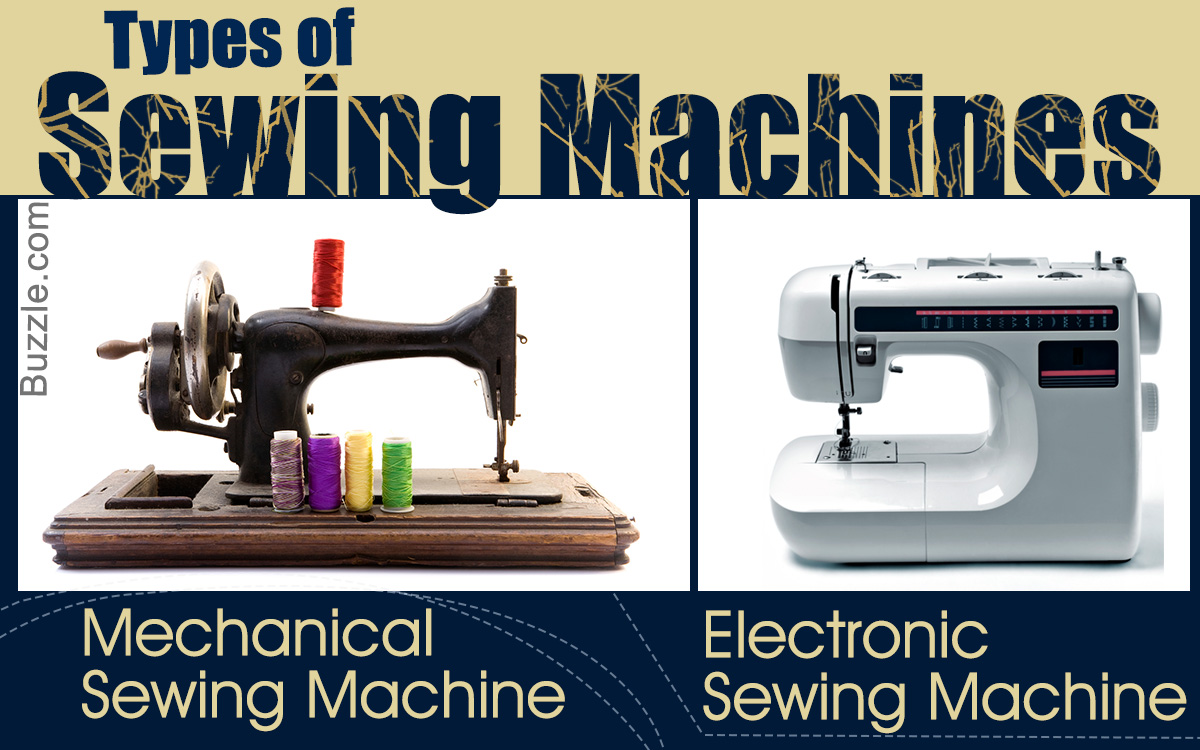

SUB-TOPIC 1: TYPES OF SEWING MACHINE AND DIFFERENT PARTS OF SEWING MACHINES AND THEIR FUNCTIONS.

The sewing machine is major sewing equipment. It is very important in successful sewing. It is also an expensive and complicated piece of equipment. It is therefore very important that one chooses it carefully and wisely. It is also important that it is handled carefully. And in order to do these, you must understand its various parts, and be able to maintain and operate it properly

Types of Sewing Machines

There are various types and makes of sewing machines. However, all sewing machines are basically similar. They may differ in types and number of kinds of stitches they make. They can also differ in the way they can be operated. The following are common types.

1. Hand sewing machine: this is simple. It is operated just with hand. It requires to be placed on a table.

2. Treadle sewing machine: this is operated with the feet. The worker has both hands free for guiding the work. It normally has a special stand.

3. Electric sewing machine: this is operated with the aid of electric motor. Some hands and treadle machines can easily be converted to electric sewing machine by using the electric motor.

Some machines make just straight stitches. Others make both straight and zigzag stitches.

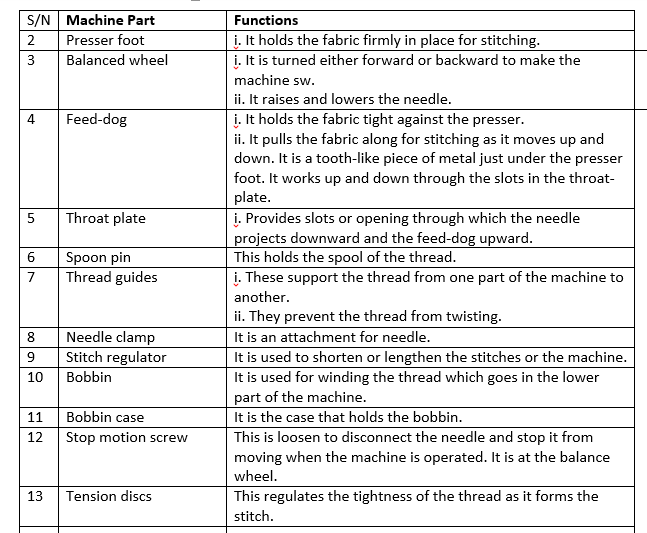

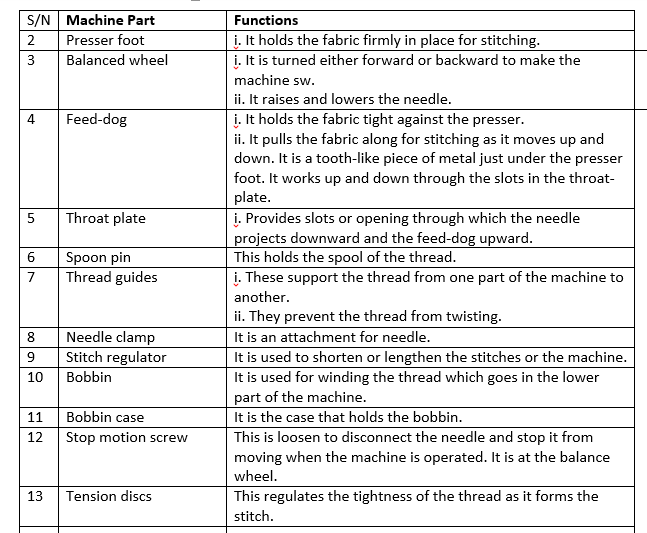

Table: Parts of a sewing machine

EVALUATION:

1. Enumerate 5 parts of a sewing machine and the function it does.

2. What function does the tension disc perform?

3. List 2 functions of the feed-dog.

4. State 5 procedures of operating a sewing machine.

SUB-TOPIC 2: GUIDELINES FOR CHOOSING A SEWING MACHINE:

1. Compare similar types of sewing machines by different manufacturers.

2. Compare their servicing arrangements, parts, prices and any other necessary information.

3. Consider the weight of the machine. Very heavy ones may be too difficult to carry about.

4. Consider the money available. Buy the best your money can afford.

5. Before paying for the machine, check to ensure that you have the instructional manual or handbook, all the accessories and spare parts that accompany the machine.

6. Before carrying away the machine, it is necessary to have the dealer demonstrate to you how it should be operated. Then try it out yourself.

EVALUATION:

1. State five guidelines for selecting a sewing machine.

ASSIGNMENT:

Work book on Home economics for Nigerian junior secondary sch. Bk 3 pgs 12-14, by Popoola o.o.

CONTENT 1: Types of Sewing Machine and Different Parts of Sewing Machines and Their Functions.

2. Guidelines for choosing a Sewing Machine

SUB-TOPIC 1: TYPES OF SEWING MACHINE AND DIFFERENT PARTS OF SEWING MACHINES AND THEIR FUNCTIONS.

The sewing machine is major sewing equipment. It is very important in successful sewing. It is also an expensive and complicated piece of equipment. It is therefore very important that one chooses it carefully and wisely. It is also important that it is handled carefully. And in order to do these, you must understand its various parts, and be able to maintain and operate it properly

Types of Sewing Machines

There are various types and makes of sewing machines. However, all sewing machines are basically similar. They may differ in types and number of kinds of stitches they make. They can also differ in the way they can be operated. The following are common types.

1. Hand sewing machine: this is simple. It is operated just with hand. It requires to be placed on a table.

2. Treadle sewing machine: this is operated with the feet. The worker has both hands free for guiding the work. It normally has a special stand.

3. Electric sewing machine: this is operated with the aid of electric motor. Some hands and treadle machines can easily be converted to electric sewing machine by using the electric motor.

Some machines make just straight stitches. Others make both straight and zigzag stitches.

Table: Parts of a sewing machine

EVALUATION:

1. Enumerate 5 parts of a sewing machine and the function it does.

2. What function does the tension disc perform?

3. List 2 functions of the feed-dog.

4. State 5 procedures of operating a sewing machine.

SUB-TOPIC 2: GUIDELINES FOR CHOOSING A SEWING MACHINE:

1. Compare similar types of sewing machines by different manufacturers.

2. Compare their servicing arrangements, parts, prices and any other necessary information.

3. Consider the weight of the machine. Very heavy ones may be too difficult to carry about.

4. Consider the money available. Buy the best your money can afford.

5. Before paying for the machine, check to ensure that you have the instructional manual or handbook, all the accessories and spare parts that accompany the machine.

6. Before carrying away the machine, it is necessary to have the dealer demonstrate to you how it should be operated. Then try it out yourself.

EVALUATION:

1. State five guidelines for selecting a sewing machine.

ASSIGNMENT:

Work book on Home economics for Nigerian junior secondary sch. Bk 3 pgs 12-14, by Popoola o.o.

Week 9

TOPIC: THE SEWING MACHINE.

CONTENT: 1. How to Use A Sewing Machine.

2. Care of sewing machine.

SUB TOPIC 1: HOW TO USE A SEWING MACHINE.

PROCEDURES FOR OPERATING SEWING MACHINE.

1. Set the machine in a good light in such a way that no shadow is thrown across the work.

2. Sit a comfortable height and square to the machine.

3. Lean forward and rest your arms just below the elbows on the table top.

4. Place the work in the machine so that the bulk of the materials is at the left-hand side where there is room for it.

5. Push both threads towards the back of the needle.

6. Lower the needle into the position required.

7. Lower the presser foot and begin to sew.

8. Use the sides of the presser foot as a guide to sew straight and watch the foot, not the needle.

9. To turn a corner, stop at the corner with the needle firmly in the fabric; raise the foot and turn the materials round, lower the foot and continue sewing.

10. To remove work from the machine:

i. Raise the presser foot.

ii. Draw thread from the machine gently by pulling above the needle so that it does not bend or break the needle.

iii. Draw the fabric out and cut through the two threads (the needle thread and the bobbin thread) leaving 10 cm of thread on each side.

To end the work, bring the two threads together and thread into a needle and make a couple of stitches forward and backward.

[youtube]https://www.youtube.com/watch?v=IGITrkYdjJs[/youtube]

[youtube]https://www.youtube.com/watch?v=i4v_k7cETis[/youtube]

EVALUATION

1. List five procedures for operating a sewing machine.

SUB-TOPIC 2:-CARE OF A SEWING MACHINE.

A sewing machine can be properly cared for in the following ways:-

1. Study the machine handbook (instruction manual) by the manufacturer before operating the machine.

2. Be sure all the parts are correctly fitted.

3. Unplug electric sewing machine before cleaning.

4. See that the machine is free from dust and fault.

5. Remove the throat plate and slide plate to expose all lint and dust clean thoroughly.

6. Oil regularly; dropping oil only as directed in the instruction.

7. Run the machine without threading or inserting any cloth for a short time.

8. Clean all parts of the machine and replace all parts after cleaning.

9. Keep a small fabric between the presser foot and the feet dog. Lower the needle into the machine, and lower the presser foot.

10. Avoid dropping the machine on the ground. Carry it carefully.

11. Let it have a permanent place to avoid damage.

12. Cover the sewing machine when not in use.

13. Make sure the instruction book is well looked after.

[youtube]https://www.youtube.com/watch?v=FmfWu83I0ZI[/youtube]

EVALUATION

Essay Test:

1. How can you determine if a machine is in a perfect condition?

2. List eight ways of caring for the sewing machine.

Objective Test:

1. A treadle machine is operated with ……..((A)motor (B)hand (C)foot (D)electric motor (E)two hands

2. The part of the sewing machine that raises and lowers the needle is ………(A)presser foot (B)balance wheel (C)head (D)feed dog (E)bobbin

3. Which of this regulates the tightness of the thread during stitching ……(A)bobbin (B)bobbin case

4. (C)needle (D)tension discs (E)motion screw

5. Which of the following holds the threaded bobbin in position ready for sewing ……….((A)bobbin winder (B)bobbin (C)bobbin case (D)bobbin machine (E)bobbin spool

6. The part of the sewing machine that sets the machine in motion is ………(A)Spool pin (B)balance wheel (C)stitch regulator (D)stop motion screw (E)presser foot

7. The thread that goes in the lower part to the machine is in the ………(A)throat plate (B)needle (C)motor (D)bobbin case (E)spool pin

8. The needle controls the thread which stitches the cloth from the ……..(A)side (B)top (C)bottom (D)bobbin (E)edge

9. When loops appear on the upper surface of the stitching , one of the following is true (A) upper tension is too tight (B) upper tension is not tight (C)lower tension is too tight (D)lower tension is not tight (E)both threads are right

10. When both upper and lower thread are too tight the fabric becomes ………(A)smooth (B)wrinkled (C)tough (D) easy (E)free

11. Incorrect threading of machine can lead to constant (A)breaking of cloth (B)stitching (C)breaking of thread (D)noise (E)joining of thread

CONTENT: 1. How to Use A Sewing Machine.

2. Care of sewing machine.

SUB TOPIC 1: HOW TO USE A SEWING MACHINE.

PROCEDURES FOR OPERATING SEWING MACHINE.

1. Set the machine in a good light in such a way that no shadow is thrown across the work.

2. Sit a comfortable height and square to the machine.

3. Lean forward and rest your arms just below the elbows on the table top.

4. Place the work in the machine so that the bulk of the materials is at the left-hand side where there is room for it.

5. Push both threads towards the back of the needle.

6. Lower the needle into the position required.

7. Lower the presser foot and begin to sew.

8. Use the sides of the presser foot as a guide to sew straight and watch the foot, not the needle.

9. To turn a corner, stop at the corner with the needle firmly in the fabric; raise the foot and turn the materials round, lower the foot and continue sewing.

10. To remove work from the machine:

i. Raise the presser foot.

ii. Draw thread from the machine gently by pulling above the needle so that it does not bend or break the needle.

iii. Draw the fabric out and cut through the two threads (the needle thread and the bobbin thread) leaving 10 cm of thread on each side.

To end the work, bring the two threads together and thread into a needle and make a couple of stitches forward and backward.

[youtube]https://www.youtube.com/watch?v=IGITrkYdjJs[/youtube]

[youtube]https://www.youtube.com/watch?v=i4v_k7cETis[/youtube]

EVALUATION

1. List five procedures for operating a sewing machine.

SUB-TOPIC 2:-CARE OF A SEWING MACHINE.

A sewing machine can be properly cared for in the following ways:-

1. Study the machine handbook (instruction manual) by the manufacturer before operating the machine.

2. Be sure all the parts are correctly fitted.

3. Unplug electric sewing machine before cleaning.

4. See that the machine is free from dust and fault.

5. Remove the throat plate and slide plate to expose all lint and dust clean thoroughly.

6. Oil regularly; dropping oil only as directed in the instruction.

7. Run the machine without threading or inserting any cloth for a short time.

8. Clean all parts of the machine and replace all parts after cleaning.

9. Keep a small fabric between the presser foot and the feet dog. Lower the needle into the machine, and lower the presser foot.