2ND TERM

2ND TERM

SCHEME OF WORK

WEEK TOPIC

1. Revision of first term work

2. Mechanical energy transmission system. (a) Friction (b) effects of friction (c) advantages and disadvantages of friction (d) methods of reducing friction (e) belt and chain drive (f) comparison with the gear drive

3. Mechanical energy transmission system. Gear. (i) Gears and gearing systems and related calculations. (ii) types of gears; internal gear, external gear,… (iii) uses of gears; power transmission, changing of direction, for selecting speed (iv) gear ratios and speed ratio (V) friction between meshed gears.

4. Mechanical energy transmission system. Motion (i) linear motion (ii) lever arrangement to produce linear motion (iii) uses of slides and slot in mechanical system (iv) Rotary motion, types of rotary motion – one way rotary motion and the reversible rotary motion. (v) Conversion of rotary motion to linear motion

5. Mechanical energy transmission system. Air flow. (i) Speed and pressure relationship in air flow. (ii) Variation of air pressure and air speed and their applications. Pneumatics; (i) simple hydraulics and pneumatics devices; simple force pump, double acting pump,… (ii) Compressed air devices, hydraulic jacks, simple garden sprinkler, reaction turbine, water wheel

6. Simple electrical wiring: (a) electrical circuit: series and parallel circuits (b) wiring tools and materials; pliers, hammer, screw driver, clips, wooden blocks, cables, etc. (c) accessories: switches, lamp holders, etc

7. Building (a) foundation (i) definition and function of foundation: support and weight of walls, roofs and inhabitants (ii) foundation types: strip, stepped, raft etc. (iii) types and properties of soil (iv) hand tools and plant for excavation: diggers, shovels, excavator, etc. (b) walls; (i) materials for making walls: grass, zinc, curtain, bricks, etc. (ii) types of walls: walls grass, zinc, curtain bricks etc. (iii) materials for bonding

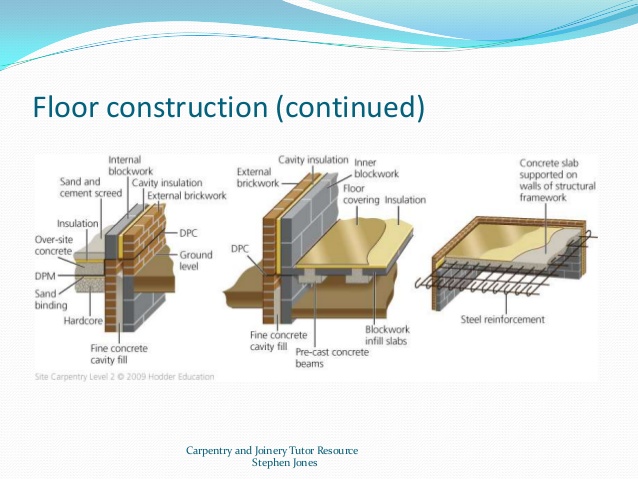

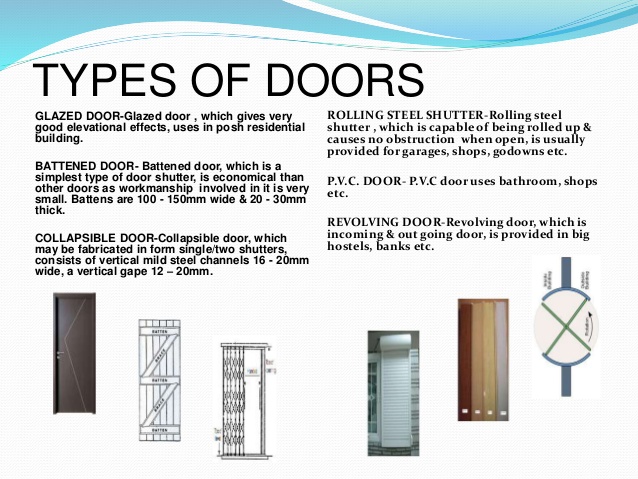

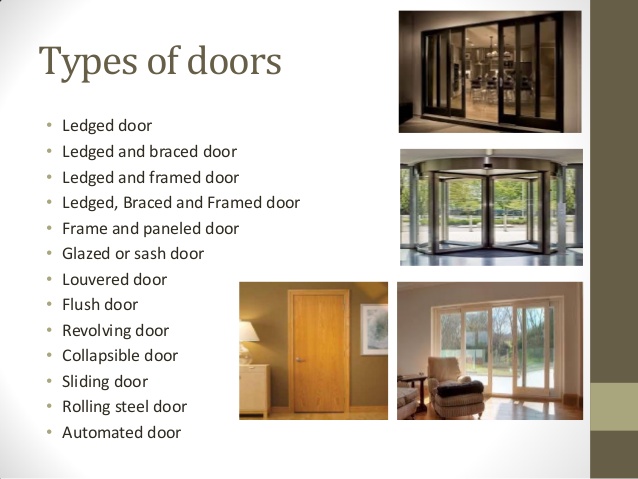

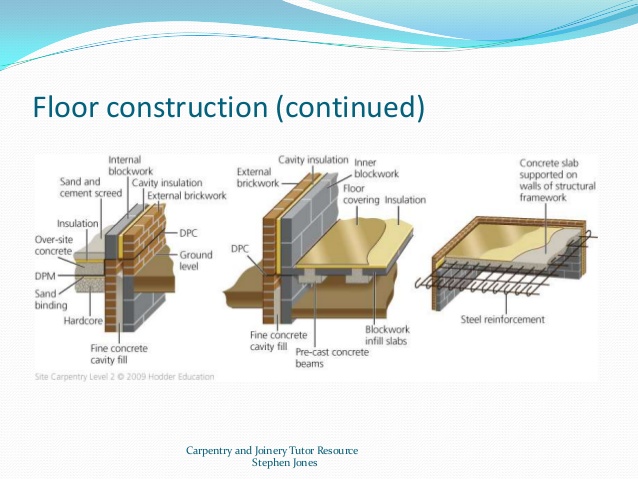

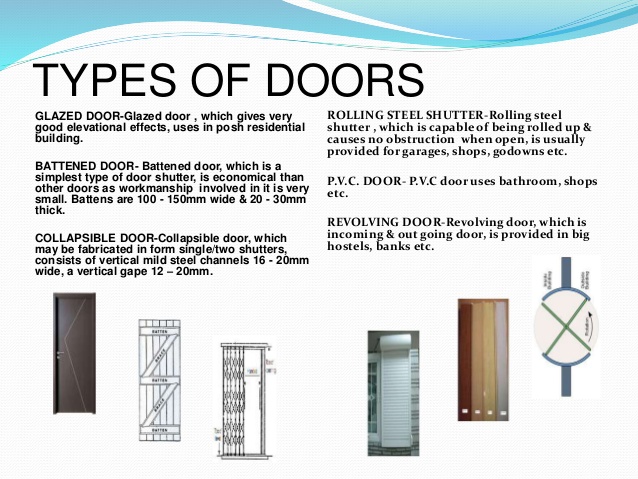

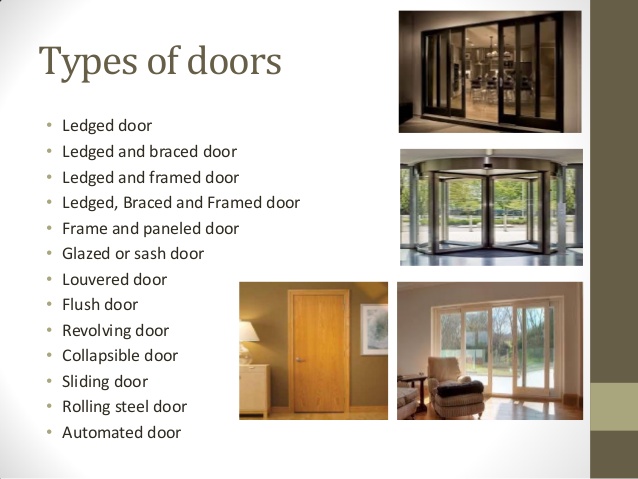

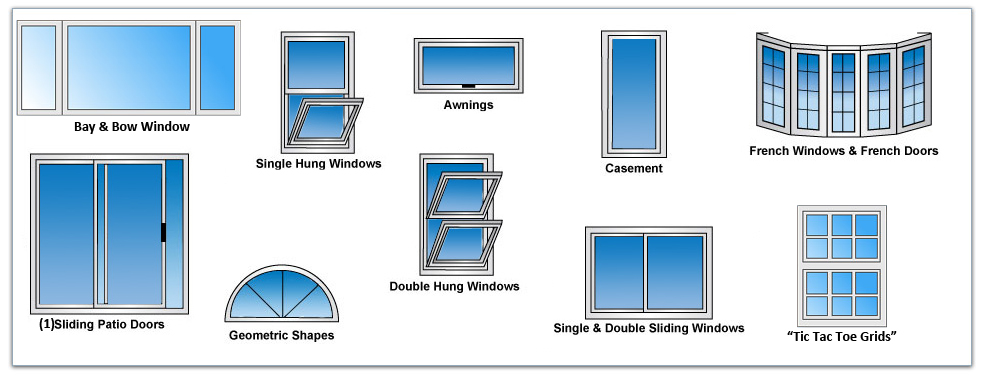

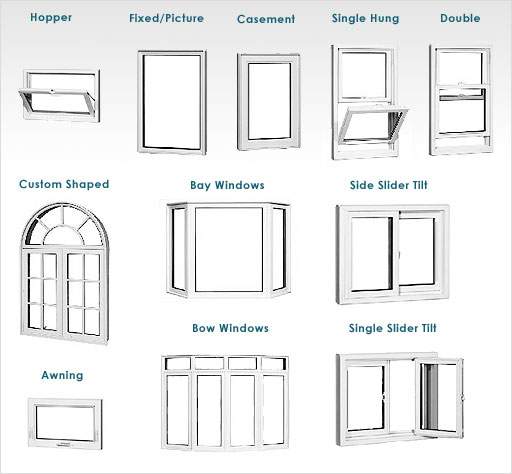

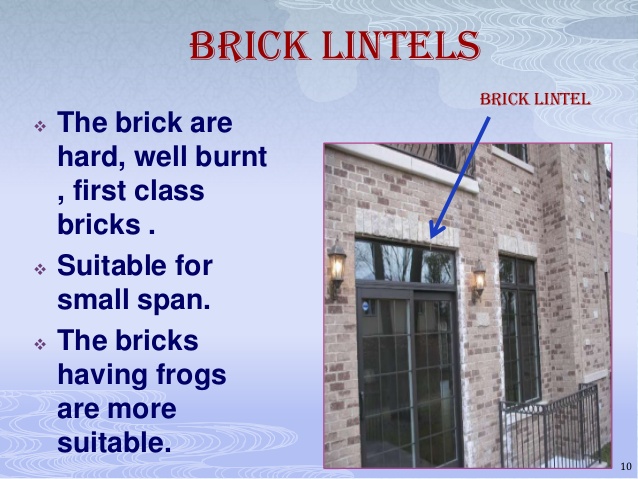

8. Building (c) floors: (i) floor: basement, ground floor, first floor, etc. (ii) DPC (d) doors, windows and openings (i) Doors: flush door, glazed, sliding, revolving, etc. (ii) windows: louver, sliding, casement, etc (iii) lintel

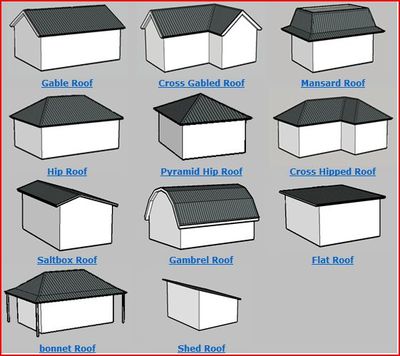

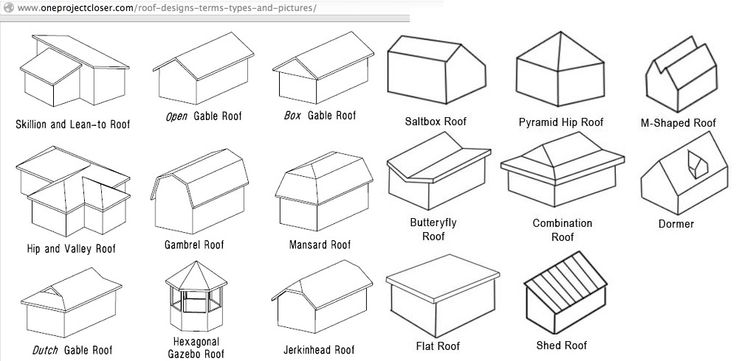

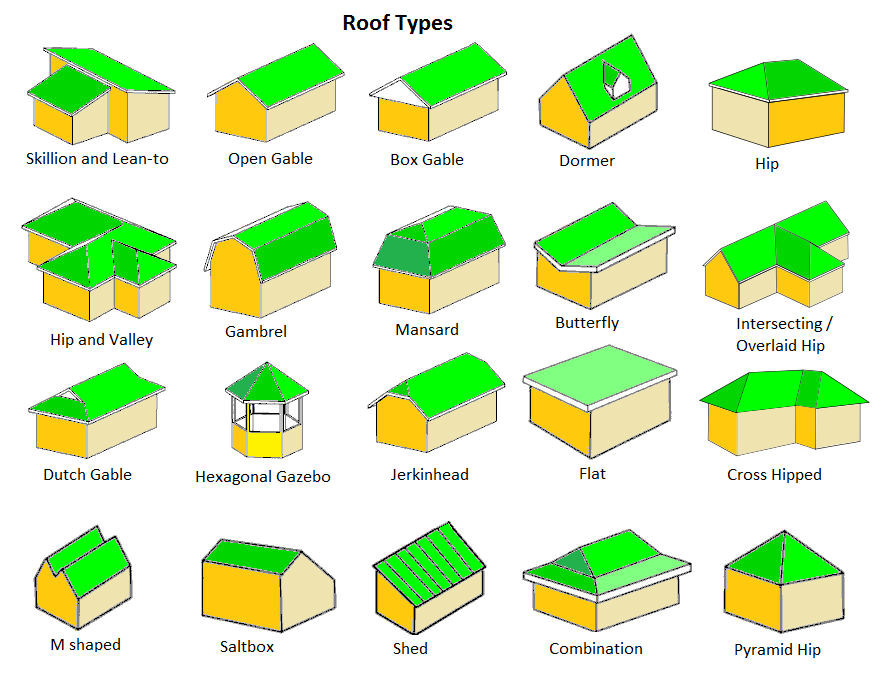

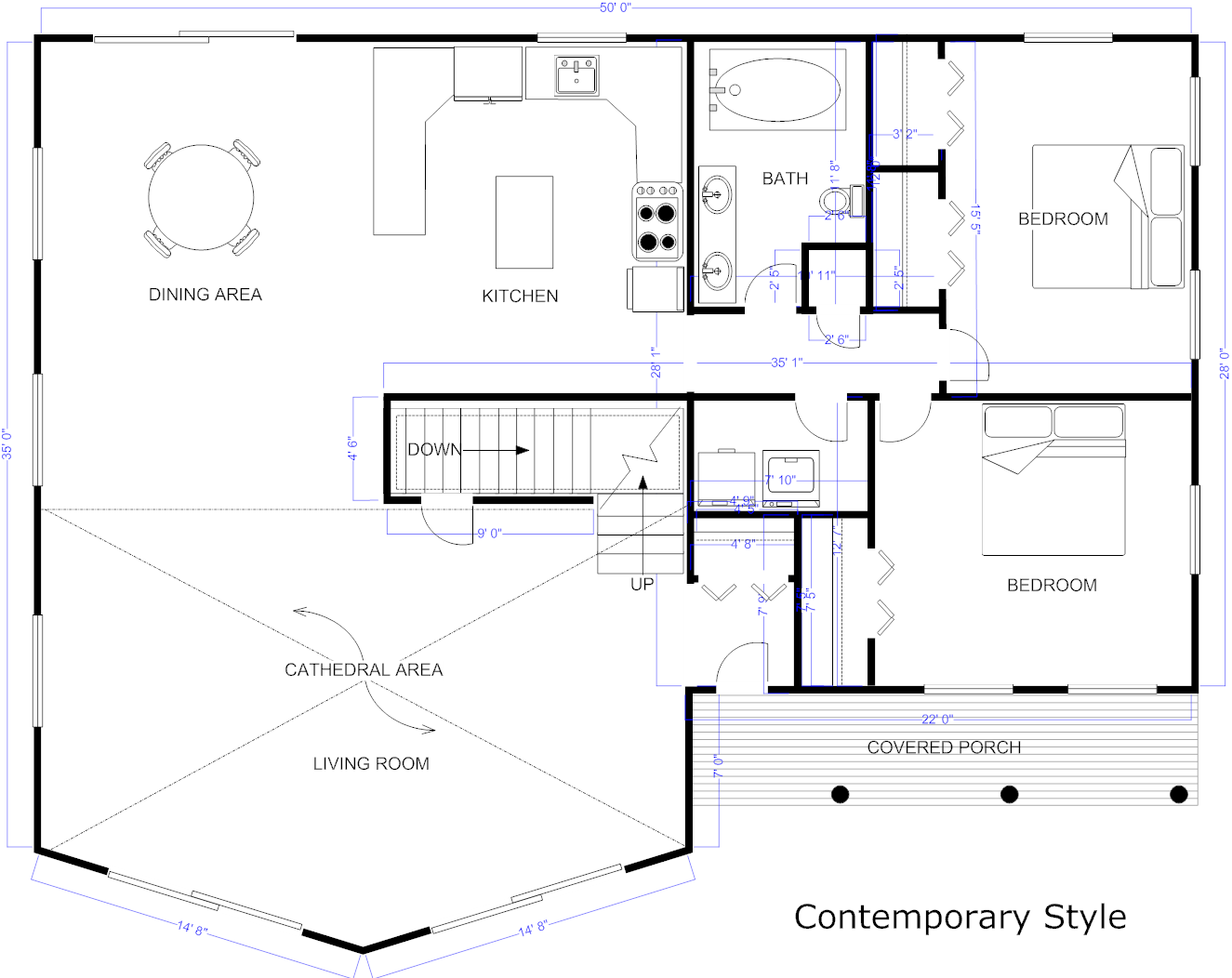

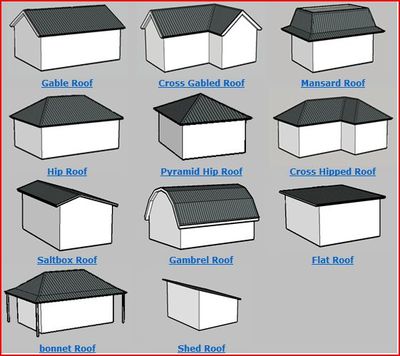

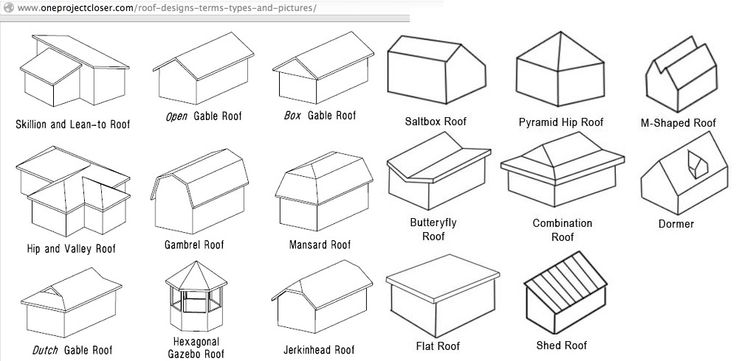

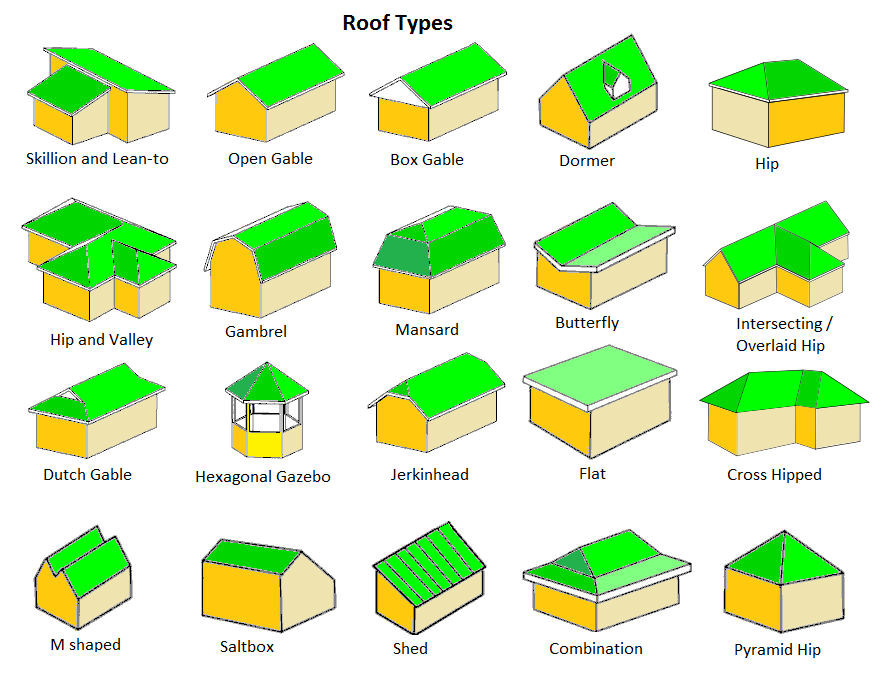

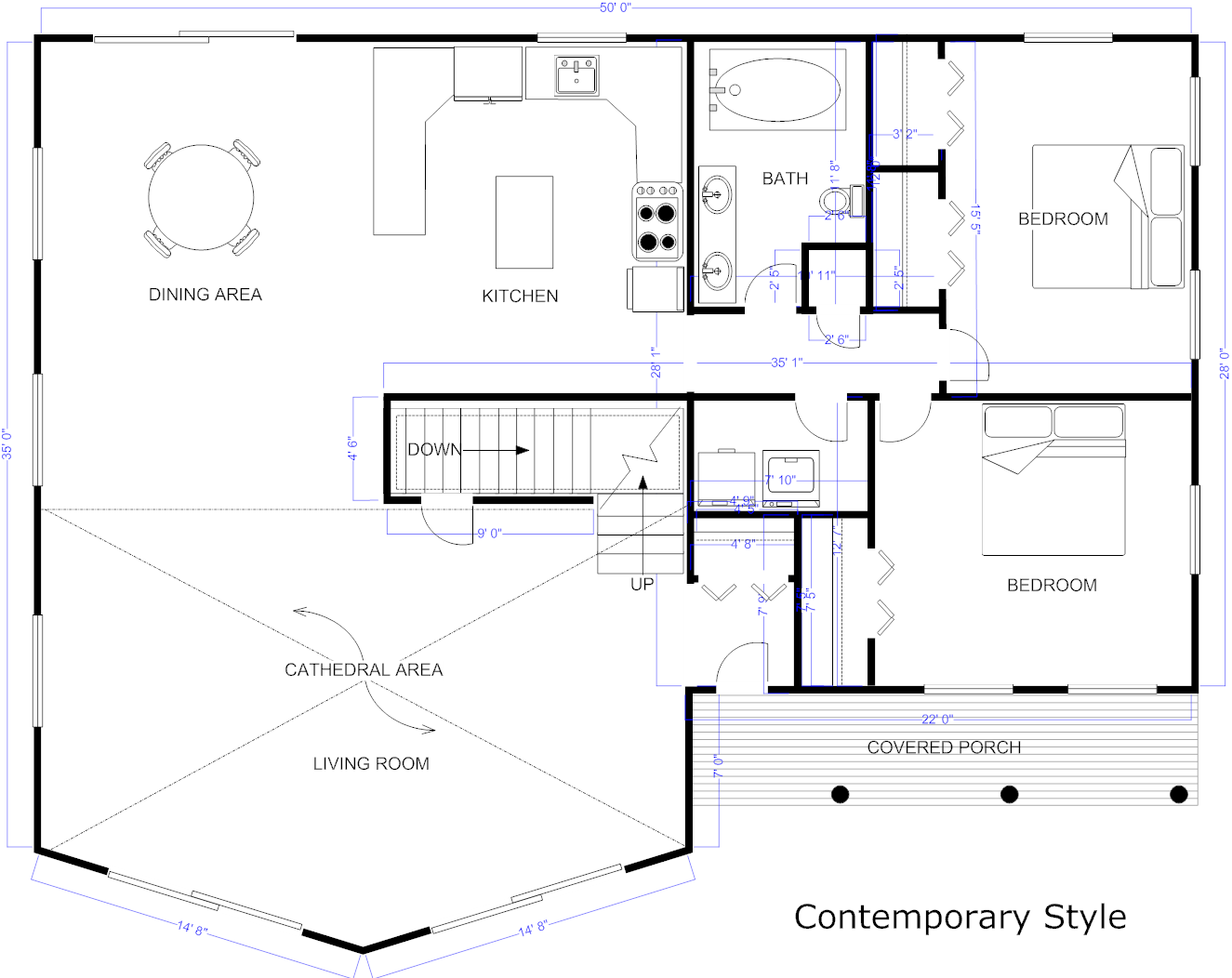

9. Building (e) Roofs (i) types of roof: flat roof, double pitched, lean-to Gable, etc (ii) roofing materials: grass, zinc, aluminium, etc. (f) simple blue print reading (I) sanitary wares: sink, bath, showers, etc. soak-away, septic tank, socket, windows, doors, room, etc.

10. Practical projects.

WEEK TOPIC

1. Revision of first term work

2. Mechanical energy transmission system. (a) Friction (b) effects of friction (c) advantages and disadvantages of friction (d) methods of reducing friction (e) belt and chain drive (f) comparison with the gear drive

3. Mechanical energy transmission system. Gear. (i) Gears and gearing systems and related calculations. (ii) types of gears; internal gear, external gear,… (iii) uses of gears; power transmission, changing of direction, for selecting speed (iv) gear ratios and speed ratio (V) friction between meshed gears.

4. Mechanical energy transmission system. Motion (i) linear motion (ii) lever arrangement to produce linear motion (iii) uses of slides and slot in mechanical system (iv) Rotary motion, types of rotary motion – one way rotary motion and the reversible rotary motion. (v) Conversion of rotary motion to linear motion

5. Mechanical energy transmission system. Air flow. (i) Speed and pressure relationship in air flow. (ii) Variation of air pressure and air speed and their applications. Pneumatics; (i) simple hydraulics and pneumatics devices; simple force pump, double acting pump,… (ii) Compressed air devices, hydraulic jacks, simple garden sprinkler, reaction turbine, water wheel

6. Simple electrical wiring: (a) electrical circuit: series and parallel circuits (b) wiring tools and materials; pliers, hammer, screw driver, clips, wooden blocks, cables, etc. (c) accessories: switches, lamp holders, etc

7. Building (a) foundation (i) definition and function of foundation: support and weight of walls, roofs and inhabitants (ii) foundation types: strip, stepped, raft etc. (iii) types and properties of soil (iv) hand tools and plant for excavation: diggers, shovels, excavator, etc. (b) walls; (i) materials for making walls: grass, zinc, curtain, bricks, etc. (ii) types of walls: walls grass, zinc, curtain bricks etc. (iii) materials for bonding

8. Building (c) floors: (i) floor: basement, ground floor, first floor, etc. (ii) DPC (d) doors, windows and openings (i) Doors: flush door, glazed, sliding, revolving, etc. (ii) windows: louver, sliding, casement, etc (iii) lintel

9. Building (e) Roofs (i) types of roof: flat roof, double pitched, lean-to Gable, etc (ii) roofing materials: grass, zinc, aluminium, etc. (f) simple blue print reading (I) sanitary wares: sink, bath, showers, etc. soak-away, septic tank, socket, windows, doors, room, etc.

10. Practical projects.

WEEK 1

TOPIC: Mechanical Energy Transmission system

Period one: Friction

Content; - Definition of friction

- Nature/characteristics of friction

- Types of frictional force

- Effect of friction

- Advantages of friction

- Disadvantages of friction

- Methods of reducing friction

Definition of friction

Friction can be defined as a force which opposes motion.

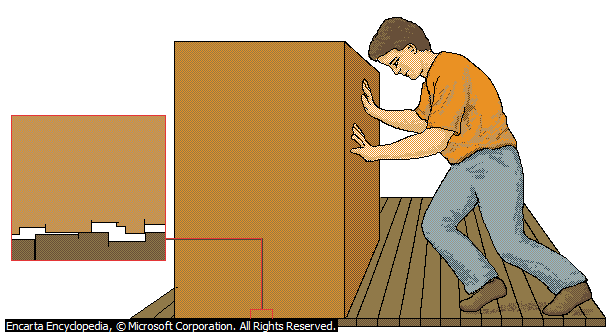

It is a force which stops/prevents motion. It acts whenever there is motion or tendency for something to move. i.e friction (or frictional force) is absent if there is no motion or if there is no force intending to cause motion. It stops your car when the brake is applied. It prevents your foot from slipping backward when you walk.

Friction can also be defined as a force of attraction between the molecules of two bodies in contact which prevents relative motion between the two bodies.

friction is preventing this box from moving.

Nature/characteristics of friction

It always opposes motion

It depends on the nature of surfaces in contact. Friction between rough surfaces is greater than the frictional force between smooth surfaces.

It does not depend on the relative speed between the two surfaces.

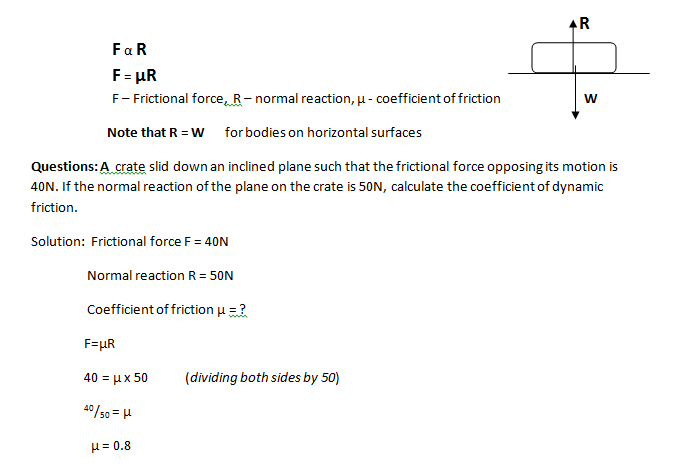

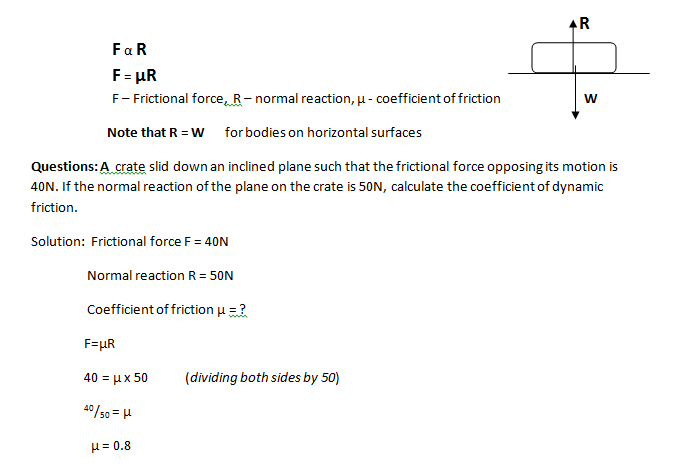

It is directly proportional to the perpendicular force (normal reaction) between the two surfaces. (R is the perpendicular force between the two surfaces in contact)

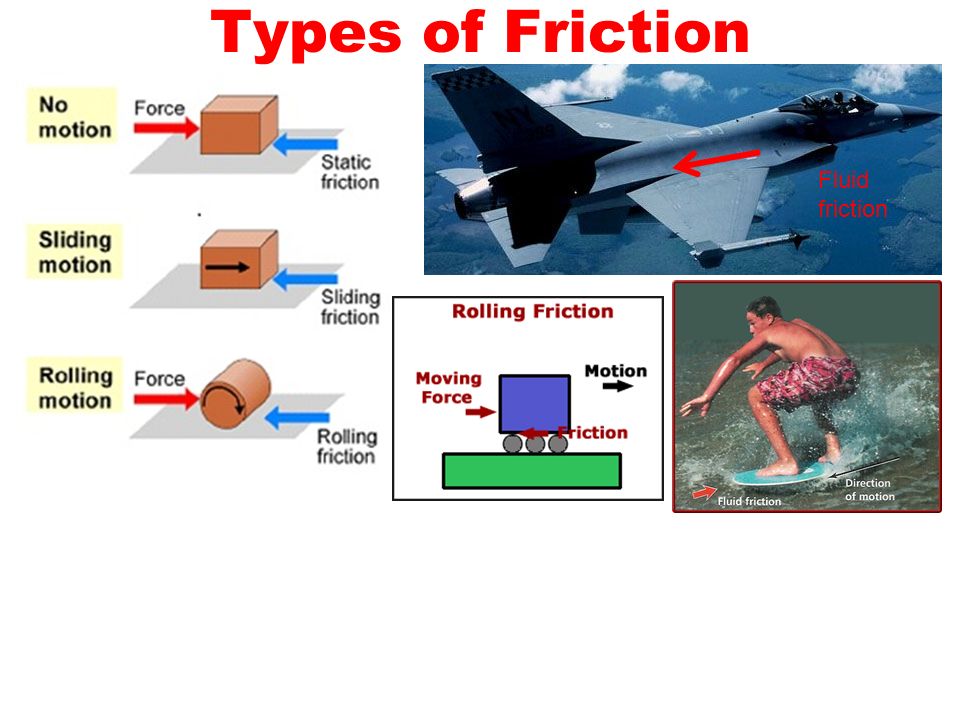

Types of friction

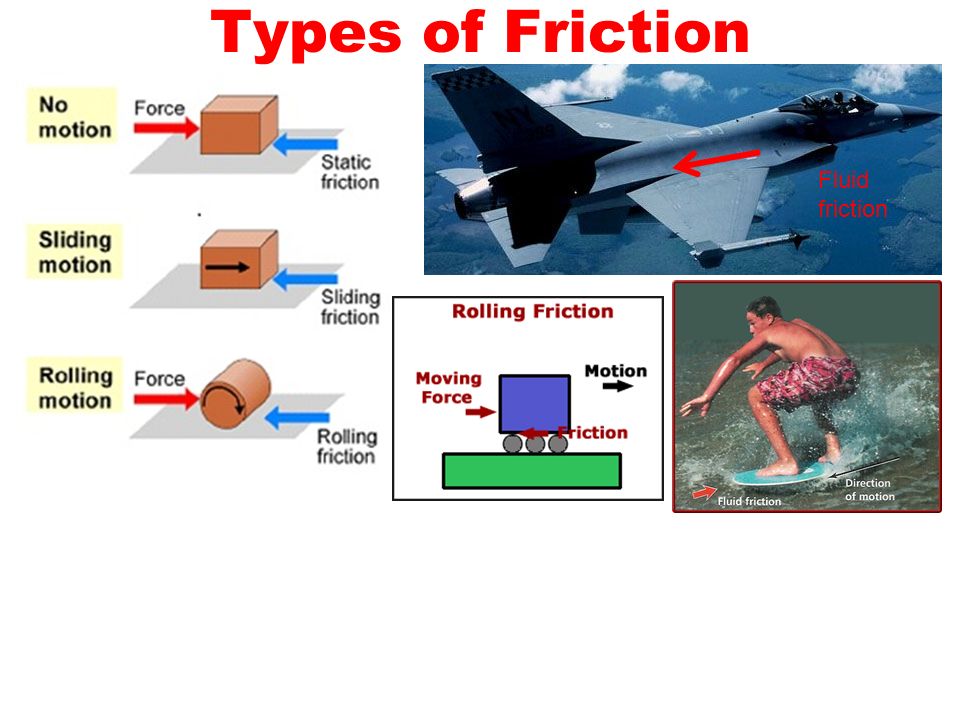

There are two types of frictional force

1. Static friction. This occurs between two bodies that are not moving or at rest.

2. Dynamic friction. This occurs between two bodies in relative motion.

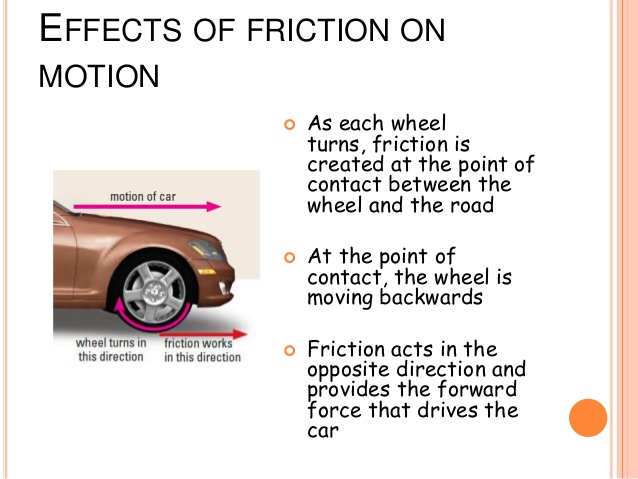

Effects of friction

Friction can best be imagined whenever there is motion or likelihood of motion. Friction exists in all machines or systems with moving parts. Friction also applies in many day to day phenomena such as; walking on a pavement, pulling the rope of a pulley system, dragging a crate on the floor, using a grinding stone for blending, loosing or tightening a nut and bolt,… . Effects of friction can be classified as desirable or undesirable.

Advantages of friction (or desirable effects of friction)

I. Locomotion: when we walk, friction between our shoes and the ground prevents our shoes from slipping backward.

II. Enhances fastening: friction between the bolt and the nut enhances their fastening ability. The friction between nails and wood also help the nail to hold woods together in firm position.

III. Blending: friction between the grinding stones helps in grinding pepper, tomatoes, this is also true of the friction between the two rough discs of the grinding machine.

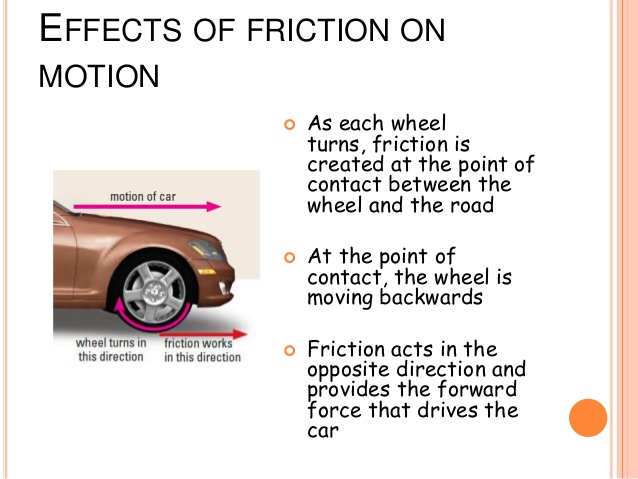

IV. Stops motion: friction between the car tyre and the road helps to stop the motion of a moving car when the brake is applied.

V. Production of electric charge: when certain materials are robbed against each other, static electric charges is produced. This principle is applied in the Van de Graff generator.

VI. Use of Ladder: when a ladder to be used to climb over a wall rest on the wall, friction between the foot of the ladder and floor prevent the foot of the ladder from slipping.

VII. Making of fire: matches sticks are ignited when they are robbed against the side of the matches’ box. Fire can also be made by striking two stones together.

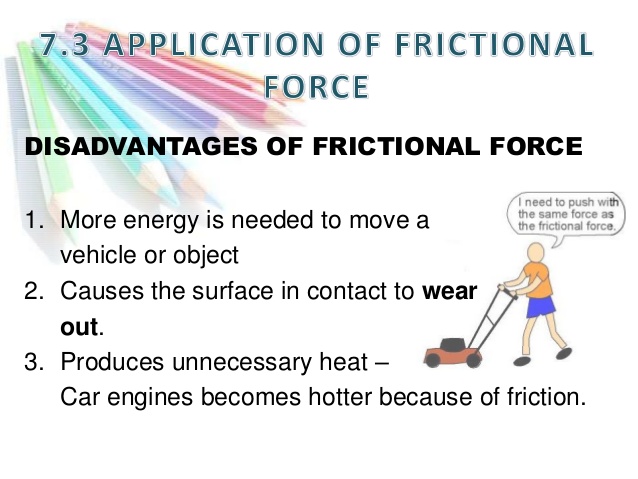

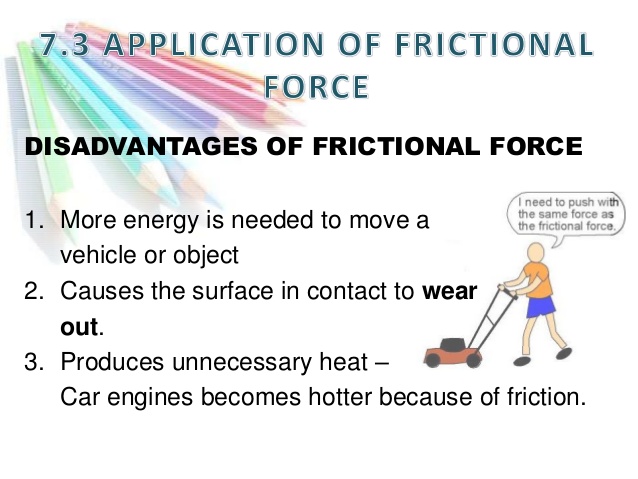

Disadvantages of friction (or undesirable effects of friction)

- Wearing: The thread pattern under your footwear soon wear out after a prolong use due to friction. This is also true of the thread on the tyre of cars and other automobile.

- Tearing/cutting: you can easily cut a piece of rope or cloth by robbing it repeatedly against the edge of the wall.

- Reduces efficiency of machines: all machines have efficiency less than 100% due to friction between their moving parts. Friction causes waste of useful energy , therefore it reduces the output of the machine.

- Generation of undesirable heat: moving machine parts/machine itself soon becomes hot due friction and this may necessitate cooling of machine parts.

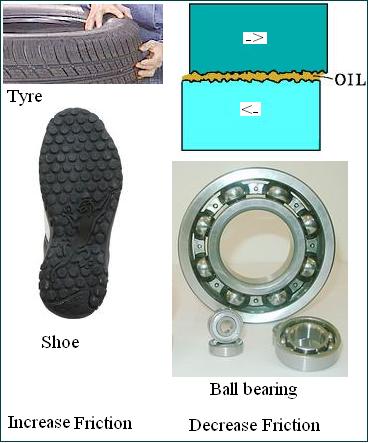

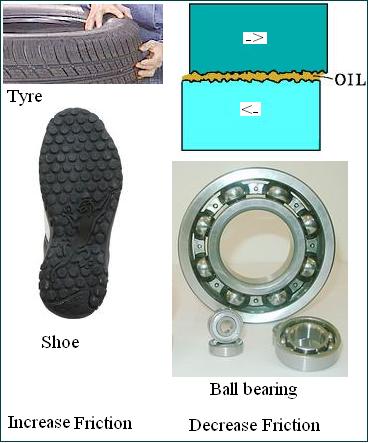

Methods of reducing friction

Due to the disadvantages of friction mentioned above, it is often necessary to reduce friction in machines. This is possible through any of the following methods:

1. Lubrication: this is the use of certain substances (called lubricants) to reduce the effects of friction. Examples of lubricants includes, grease, oil,… many of which are petroleum products.

2. Use of rollers

3. Use of ball bearing

4. Use of belt/chain drive

Period two: Belt and Chain drive

Content:

- Drives

- Belt drive

- Types of belt drive

- Belt tensioning

- Application of belt drive

- Chain drive

- Application of chain drive

- Difference between chain drive and gear drive

Drives: Drives are devices used to transmit rotary motion from one shaft to another.

The drive mechanism is used in transmitting power from one location to another

There are three types of drives:

1. Belt and pulley drive

2. Chain drives

3. Gear drives

Belt drive

This is a device used to transfer power/motion from one shaft to another shaft parallel to it and at some distance away. Belt drives are often used in place of chain drive when slip is not so important to be taken into consideration. Hence, belt cannot provide positive drive because slip occurs from time to time.

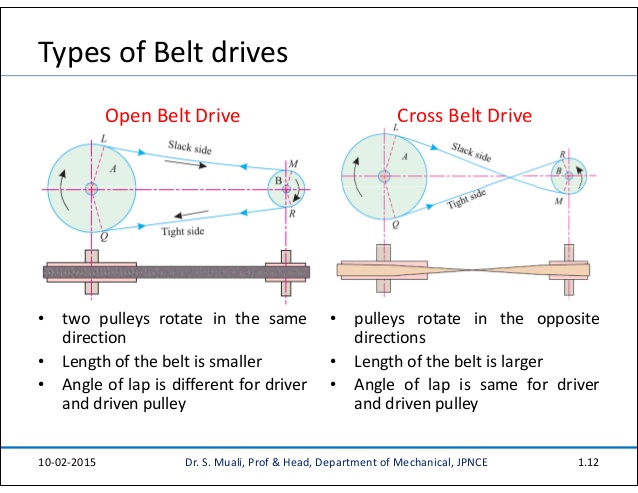

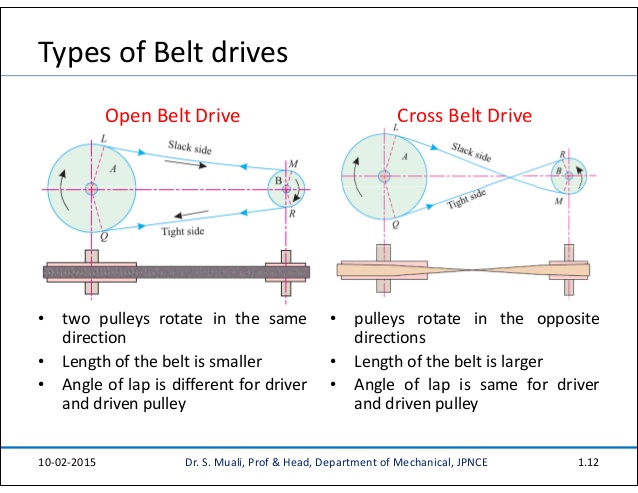

Types of belt drive

There are two types of belt drive based on the shape of the belt:

1. Straight (flat) belt

2. V- shaped belt

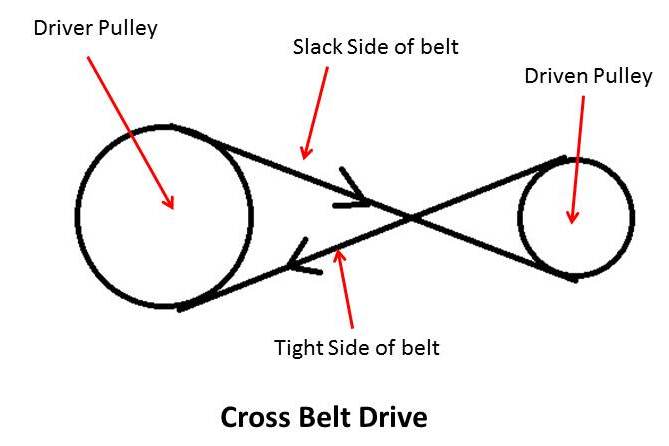

Belt can be lapped over the groove pulley in two styles. This includes:

i. Straight belt lap: Here the two pulleys join by the belt rotate in the same direction.

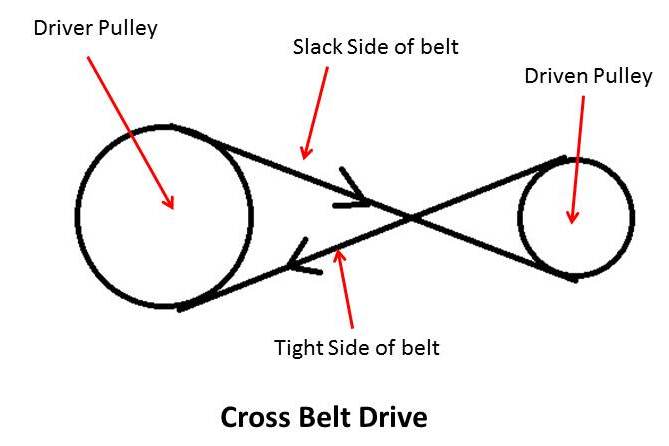

ii. Cross belt lap: Here the two pulleys join by the belt rotate in opposite

Straight belt lap

Cross belt lap

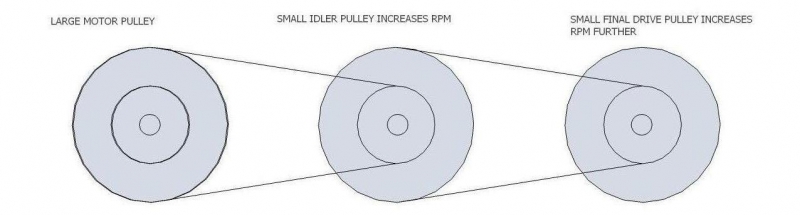

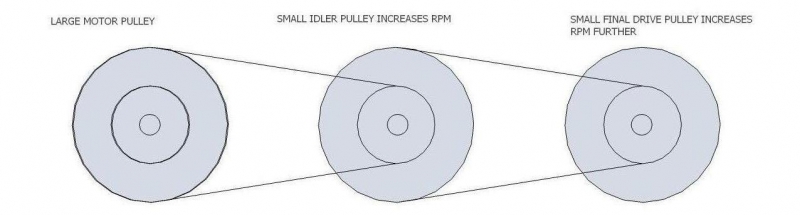

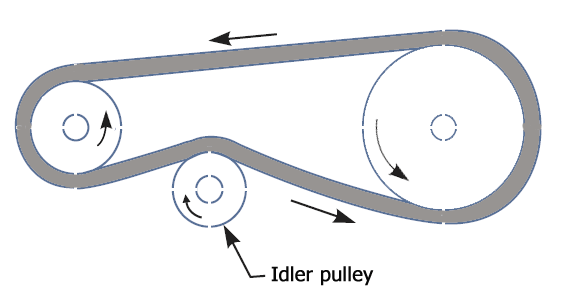

Belt tensioning

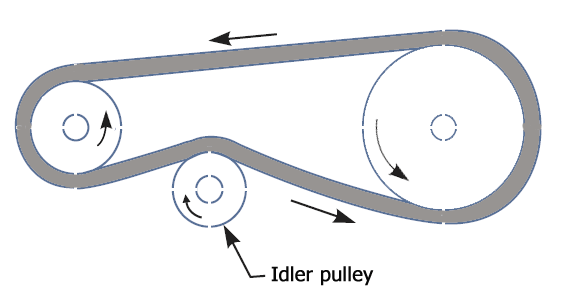

Sometimes, a belt in use is slack and may be slipping over the pulley. Such belts that are not taut do not transmit motion/power effectively thereby wasting energy. This could be prevented by tensioning the belt drive.

To tension a belt, another pulley (wheel called the idler) mounted on a separate shaft is used.

Idler

Application of belt drive

1. They are used to couple a diesel engine to an alternator to generate electricity

2. They are used in cassava grinding machines

3. They are used for the radiator of cars.

4. They are used for tape recorders/ video cassette players

5. They are used in the engines of automobiles (Volkswagens –tortoise car)

6. They are used in block making machines

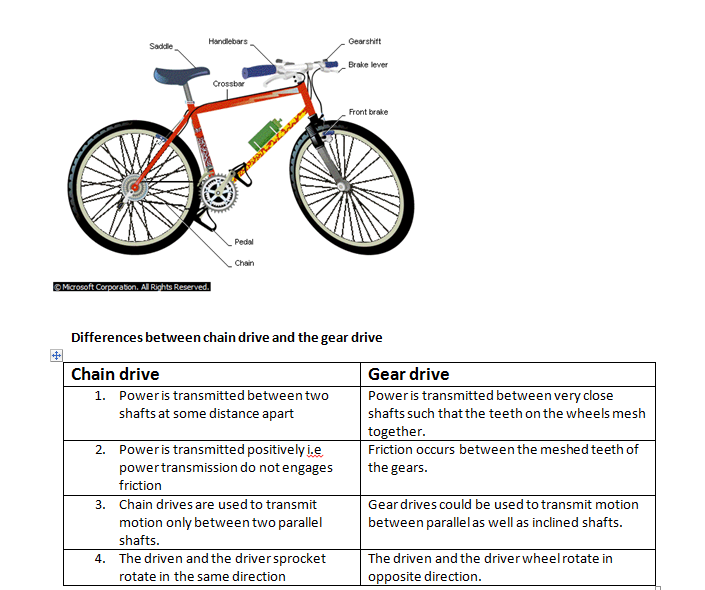

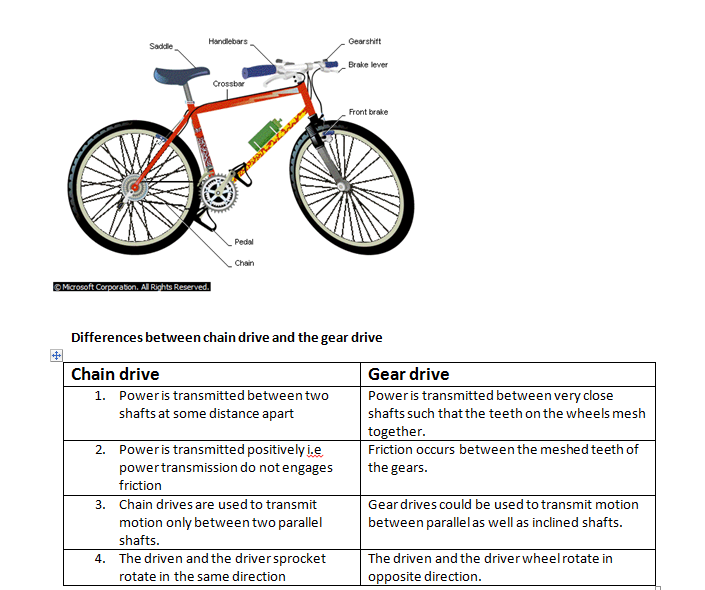

Chain drives

They are used for transferring power/motion from one shaft to another just as in the case for belt drive. Chain is always used in conjunction with a sprocket for transmitting power. A sprocket is a toothed wheel or a wheel with many contours round its circumference. The number of teeth on the sprockets determines the speed of rotation of the driven sprocket.

One advantage of the chain and sprocket drive over the belt drive is that it has a firmer grip on the area of lap than the belt drive. Chain drives do not allow slip unlike belt drive. Also, power is transmitted positively in chain drive and not by friction as in the case of belt drives.

In chain drive, the driver and the driven sprocket rotate in the same direction just as in the case of straight belt lap. Both the chain drive and the belt drives are used to transmit power and motion between two shafts at some distance apart.

Applications of chain drive.

1. The motorcycle chain drive

2. The bicycle chain and sprocket drive.

3. Mechanical saw for slicing wood.

Practical

The students should inspect the following

i. Bicycle chain and sprocket drive

ii. Interior of a radio cassette player with the belt in action or the belt of the car radiator in action

iii. Ball bearing for reducing friction.

The students are to make note and discuss among themselves their various observations.

EVALUATION

1. A force which opposes motion is called --- (a) tension (b) elastic (c) friction (d) pull

2. A process of applying a substance to machine parts in order to reduce friction is called --- (a) lubrication (b) elimination (c) banking (d) friction control

3. --- is a type of friction which occurs between two bodies in relative motion. (a) moving friction (b) static friction (c) lubricating friction (d) dynamic friction

4. Which of these drives involves positive transfer of motion? (a) gear drive (b) belt drive (c) chain drive (d) friction drive

5. Block moulding machine is an application of the --- (a) belt drive (b) gear drive (c) chain drive (d) sprocket drive

6. There are --- types of drives. (a) 1 (b)2 (c) 3 (d) 4

Assignment

i. State two differences and two similarities between the belt drive and the chain drive

ii. Mention two advantages of chain drive over the gear drive.

ASSIGNMENT

1. Define the following terms

i. Gear drive

ii. Gear ratio

2. List five types of gears.

Period one: Friction

Content; - Definition of friction

- Nature/characteristics of friction

- Types of frictional force

- Effect of friction

- Advantages of friction

- Disadvantages of friction

- Methods of reducing friction

Definition of friction

Friction can be defined as a force which opposes motion.

It is a force which stops/prevents motion. It acts whenever there is motion or tendency for something to move. i.e friction (or frictional force) is absent if there is no motion or if there is no force intending to cause motion. It stops your car when the brake is applied. It prevents your foot from slipping backward when you walk.

Friction can also be defined as a force of attraction between the molecules of two bodies in contact which prevents relative motion between the two bodies.

friction is preventing this box from moving.

Nature/characteristics of friction

It always opposes motion

It depends on the nature of surfaces in contact. Friction between rough surfaces is greater than the frictional force between smooth surfaces.

It does not depend on the relative speed between the two surfaces.

It is directly proportional to the perpendicular force (normal reaction) between the two surfaces. (R is the perpendicular force between the two surfaces in contact)

Types of friction

There are two types of frictional force

1. Static friction. This occurs between two bodies that are not moving or at rest.

2. Dynamic friction. This occurs between two bodies in relative motion.

Effects of friction

Friction can best be imagined whenever there is motion or likelihood of motion. Friction exists in all machines or systems with moving parts. Friction also applies in many day to day phenomena such as; walking on a pavement, pulling the rope of a pulley system, dragging a crate on the floor, using a grinding stone for blending, loosing or tightening a nut and bolt,… . Effects of friction can be classified as desirable or undesirable.

Advantages of friction (or desirable effects of friction)

I. Locomotion: when we walk, friction between our shoes and the ground prevents our shoes from slipping backward.

II. Enhances fastening: friction between the bolt and the nut enhances their fastening ability. The friction between nails and wood also help the nail to hold woods together in firm position.

III. Blending: friction between the grinding stones helps in grinding pepper, tomatoes, this is also true of the friction between the two rough discs of the grinding machine.

IV. Stops motion: friction between the car tyre and the road helps to stop the motion of a moving car when the brake is applied.

V. Production of electric charge: when certain materials are robbed against each other, static electric charges is produced. This principle is applied in the Van de Graff generator.

VI. Use of Ladder: when a ladder to be used to climb over a wall rest on the wall, friction between the foot of the ladder and floor prevent the foot of the ladder from slipping.

VII. Making of fire: matches sticks are ignited when they are robbed against the side of the matches’ box. Fire can also be made by striking two stones together.

Disadvantages of friction (or undesirable effects of friction)

- Wearing: The thread pattern under your footwear soon wear out after a prolong use due to friction. This is also true of the thread on the tyre of cars and other automobile.

- Tearing/cutting: you can easily cut a piece of rope or cloth by robbing it repeatedly against the edge of the wall.

- Reduces efficiency of machines: all machines have efficiency less than 100% due to friction between their moving parts. Friction causes waste of useful energy , therefore it reduces the output of the machine.

- Generation of undesirable heat: moving machine parts/machine itself soon becomes hot due friction and this may necessitate cooling of machine parts.

Methods of reducing friction

Due to the disadvantages of friction mentioned above, it is often necessary to reduce friction in machines. This is possible through any of the following methods:

1. Lubrication: this is the use of certain substances (called lubricants) to reduce the effects of friction. Examples of lubricants includes, grease, oil,… many of which are petroleum products.

2. Use of rollers

3. Use of ball bearing

4. Use of belt/chain drive

Period two: Belt and Chain drive

Content:

- Drives

- Belt drive

- Types of belt drive

- Belt tensioning

- Application of belt drive

- Chain drive

- Application of chain drive

- Difference between chain drive and gear drive

Drives: Drives are devices used to transmit rotary motion from one shaft to another.

The drive mechanism is used in transmitting power from one location to another

There are three types of drives:

1. Belt and pulley drive

2. Chain drives

3. Gear drives

Belt drive

This is a device used to transfer power/motion from one shaft to another shaft parallel to it and at some distance away. Belt drives are often used in place of chain drive when slip is not so important to be taken into consideration. Hence, belt cannot provide positive drive because slip occurs from time to time.

Types of belt drive

There are two types of belt drive based on the shape of the belt:

1. Straight (flat) belt

2. V- shaped belt

Belt can be lapped over the groove pulley in two styles. This includes:

i. Straight belt lap: Here the two pulleys join by the belt rotate in the same direction.

ii. Cross belt lap: Here the two pulleys join by the belt rotate in opposite

Straight belt lap

Cross belt lap

Belt tensioning

Sometimes, a belt in use is slack and may be slipping over the pulley. Such belts that are not taut do not transmit motion/power effectively thereby wasting energy. This could be prevented by tensioning the belt drive.

To tension a belt, another pulley (wheel called the idler) mounted on a separate shaft is used.

Idler

Application of belt drive

1. They are used to couple a diesel engine to an alternator to generate electricity

2. They are used in cassava grinding machines

3. They are used for the radiator of cars.

4. They are used for tape recorders/ video cassette players

5. They are used in the engines of automobiles (Volkswagens –tortoise car)

6. They are used in block making machines

Chain drives

They are used for transferring power/motion from one shaft to another just as in the case for belt drive. Chain is always used in conjunction with a sprocket for transmitting power. A sprocket is a toothed wheel or a wheel with many contours round its circumference. The number of teeth on the sprockets determines the speed of rotation of the driven sprocket.

One advantage of the chain and sprocket drive over the belt drive is that it has a firmer grip on the area of lap than the belt drive. Chain drives do not allow slip unlike belt drive. Also, power is transmitted positively in chain drive and not by friction as in the case of belt drives.

In chain drive, the driver and the driven sprocket rotate in the same direction just as in the case of straight belt lap. Both the chain drive and the belt drives are used to transmit power and motion between two shafts at some distance apart.

Applications of chain drive.

1. The motorcycle chain drive

2. The bicycle chain and sprocket drive.

3. Mechanical saw for slicing wood.

Practical

The students should inspect the following

i. Bicycle chain and sprocket drive

ii. Interior of a radio cassette player with the belt in action or the belt of the car radiator in action

iii. Ball bearing for reducing friction.

The students are to make note and discuss among themselves their various observations.

EVALUATION

1. A force which opposes motion is called --- (a) tension (b) elastic (c) friction (d) pull

2. A process of applying a substance to machine parts in order to reduce friction is called --- (a) lubrication (b) elimination (c) banking (d) friction control

3. --- is a type of friction which occurs between two bodies in relative motion. (a) moving friction (b) static friction (c) lubricating friction (d) dynamic friction

4. Which of these drives involves positive transfer of motion? (a) gear drive (b) belt drive (c) chain drive (d) friction drive

5. Block moulding machine is an application of the --- (a) belt drive (b) gear drive (c) chain drive (d) sprocket drive

6. There are --- types of drives. (a) 1 (b)2 (c) 3 (d) 4

Assignment

i. State two differences and two similarities between the belt drive and the chain drive

ii. Mention two advantages of chain drive over the gear drive.

ASSIGNMENT

1. Define the following terms

i. Gear drive

ii. Gear ratio

2. List five types of gears.

WEEK 2

TOPIC: GEAR DRIVE

CONTENT:

Gear drive

Seizure

Types of gears

Use of gear drive

Gear ratio

Speed ratio

Changing direction of drive

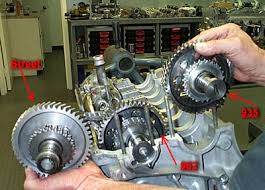

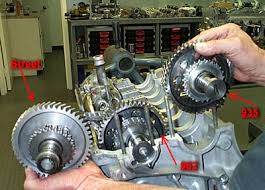

Gear drive

This is a device used to transmit motion between parallel or inclined shafts that are close to each other (such that the tooth on the wheel mounted on the shafts mesh together). When two gears are in mesh, they are called GEAR TRAIN. Friction always occurs between the meshed teeth of the gear train. Constant lubrication is therefore necessary to prevent wearing. The teeth on each gears in mesh must be uniformly spaced around the gear (that is symmetrical) for them to mesh properly and to prevent damage of the tooth. Improperly meshed gears can also lead to seizure of the gear train.

Seizure is the total movement stoppage of the gear train.

Unlike the belt and the chain drive, the driver and the driven gear move in different direction. To make the driver and the driven gear move in the same direction, another gear (called the IDLER) is inserted between the two (driver and the driven gear).

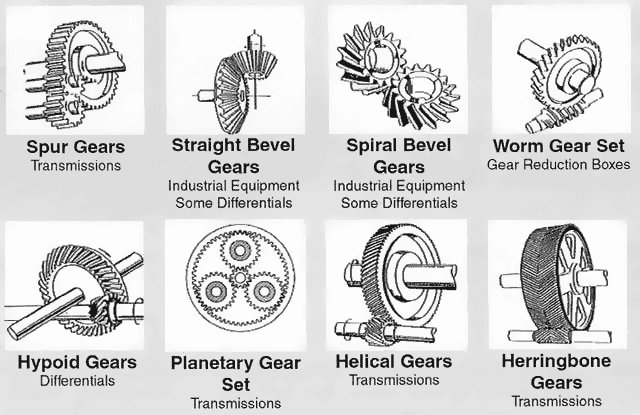

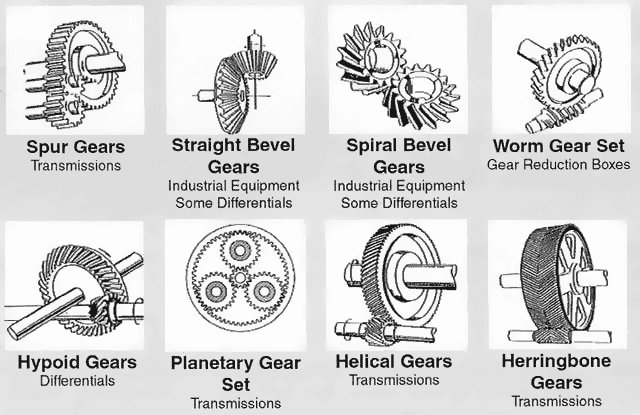

Types of gears

Spur gear: this has teeth parallel to the shaft of the gear.

Helical gear: this has teeth inclined to the shaft of the gear.

Worm gears: these are gears formed when a spur gear mesh with a screw.

Rack and pinion: these are gears that run on a flat toothed rack.

Planetary gears: these consist of a number of spur gear meshed with one another and another gear with internal gear.

Bevel gears: these are gears used when power is to be transmitted between inclined shafts

Uses of gear drive

To transmit motion between two inclined or parallel shafts.

To change direction of motion.

For speed selection .

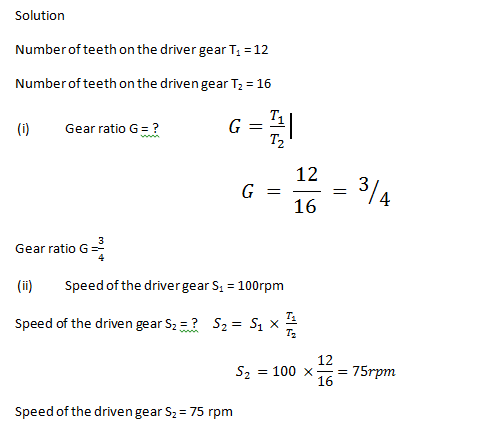

Gear ratio

This can be defined as the ratio of the number of teeth on the driver gear to that on the driven gear

G=T[sub]1[/sub]/T[sub]2[/sub]

T[sub]1[/sub] is number of teeth on driver gear

T[sub]2[/sub] is number of teeth on driven gear

Speed ratio

This can be defined as the ratio of the speed of the driven gear to the speed of the driver gear.

S=S[sub]2[/sub]/S[sub]1[/sub]

S[sub]1[/sub] speed of the driver gear

S[sub]2[/sub] is speed of the driven gear

The gear ratio and the speed ratio of a gear train are equal. The speed of rotation of the driven gear depends on the number of teeth on the driven and the driver gear. Where a large increase in speed is desired (like in the case of motor car), a compound gear train is used.

Compound gear

The speed of the driven gear S[sub]2[/sub] is given as

S[sub]2[/sub] = S[sub]1[/sub] × T[sub]1[/sub]/T[sub]2[/sub]

Where each symbols has it usual meaning.

Changing the direction of drive,

Chain drives cannot be used for changing the direction of rotation of drives. Belt drive cannot be used to change direction of rotation of drive except when belt is crossed. Gears can be used for changing the direction of motion. The bevelled gear is often used for changing direction of motion between two perpendicular/inclined shafts.

EVALUATION

Which of these drives can be used to change the direction of rotation? (a) straight lap belt (b) chain drive (c) gear drive (d) none of the above

A gear with tooth parallel to the shaft is called ---(a) helical gear (b) planetary gear (c) worm gear (d) spur gear

The ratio of the speed of driver gear to the speed of the driven gear is --- (a) gear ratio (b) speed ratio (c) velocity ratio (d) none of the above

Answers

(c) 2. (d) 3. (d)

PERIOD TWO

CONTENT

CALCULATIONS ON GEAR AND SPEED RATIO

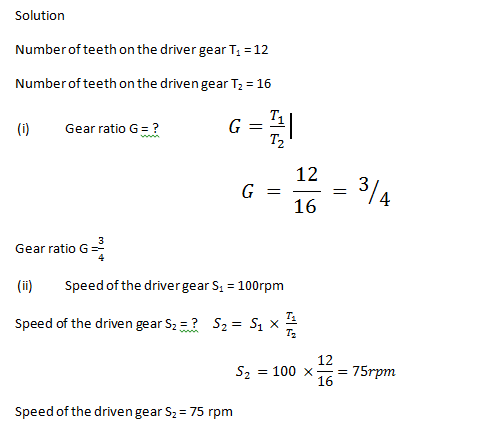

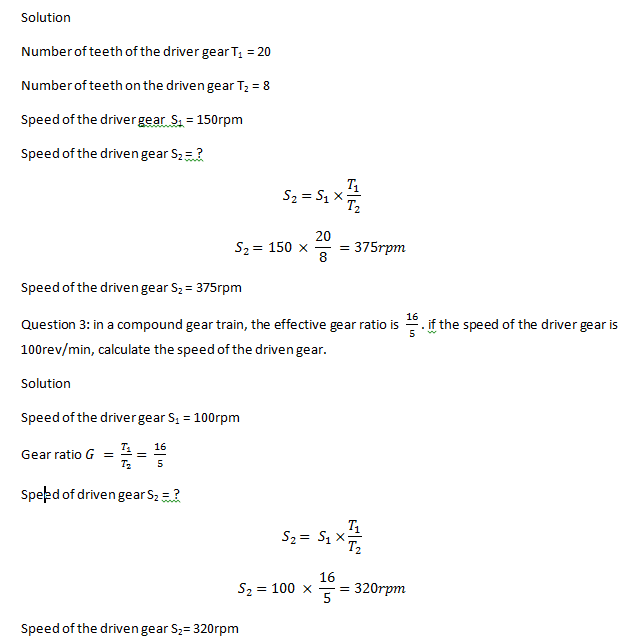

Question 1: the number of teeth on the driver and the driven gear is 12 and 16 respectively. If the speed of the driver gear is 100rev/min, calculate (i) the gear ratio (ii) speed of the driven gear

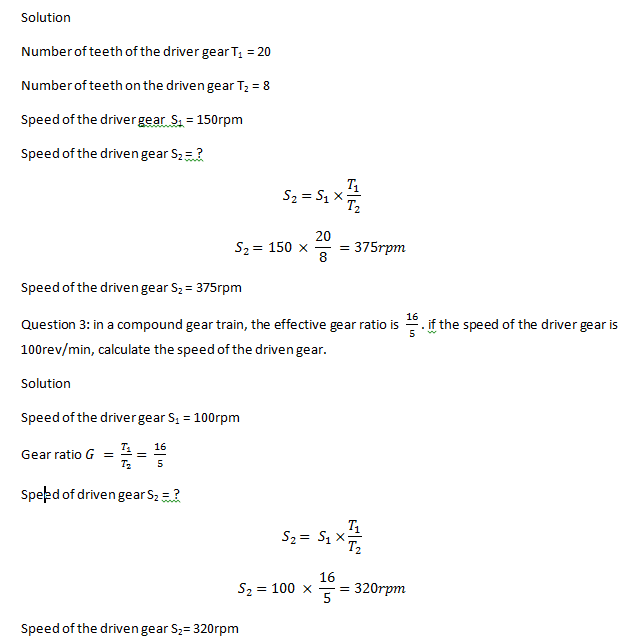

Question 2: A gear train is such that the number of teeth on the driver gear is 20 while that on the driven is 8. If the speed of the driver gear is 150rev/min. calculate the speed of the driven gear.

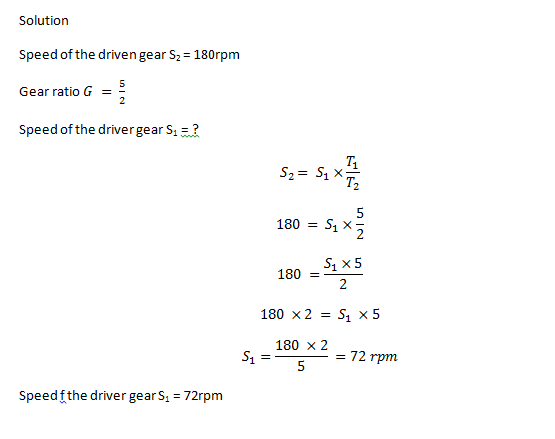

Question 4: A gear train has a gear ratio of 5/2 and a driven gear rotating at a speed of 180 revolution per minute. What would have been the speed of the driver gear?

Practical

Using hard cardboard gear of different radii and their centres with nail at different portion on a wood, the students should demonstrate the operation of compound gear.

Evaluation question

Which of these gears is a combination of a spur gear and a screw? (a) bevel gears (b) helical gear (c) spur gear (d) worm gear

A condition in which the movement of a gear system is halted due to a spoil is known as ---- (a) slip (b) seizure (c) reverse (d) bevel

The friction between the teeth of meshed gears can be reduced BY (a) avoiding the use of gear (b) exposing gear to air (c)Lubrication (d)aeration

The major use of drive is to (a) transmit motion (b) change direction of motion (c) reduce speed (d) avoid friction

The ratio of the number of teeth on the driven gear to the number of teeth on the driver gear is called (a) speed ratio (b) gear proportion (c) gear ratio (d) none of the above

The gear ratio of a gear train is [sup]7[/sup]/[sub]4[/sub] and the speed of the driver gear is 80rpm. What is the speed of the driven gear? (a) 70rpm (b) 140rpm (c) 150rpm (d) 210rpm

ASSIGNMENT

Consult your textbook and make a list of ten types of gear.

List five applications of the gear drives

READING ASSIGNMENT: Read your Basic Technology textbook by Olawehinmi, pages 160 - 169 and answer the following questions.

Define motion.

Write a short note on the following (i) linear motion (ii) rotary motion.

CONTENT:

Gear drive

Seizure

Types of gears

Use of gear drive

Gear ratio

Speed ratio

Changing direction of drive

Gear drive

This is a device used to transmit motion between parallel or inclined shafts that are close to each other (such that the tooth on the wheel mounted on the shafts mesh together). When two gears are in mesh, they are called GEAR TRAIN. Friction always occurs between the meshed teeth of the gear train. Constant lubrication is therefore necessary to prevent wearing. The teeth on each gears in mesh must be uniformly spaced around the gear (that is symmetrical) for them to mesh properly and to prevent damage of the tooth. Improperly meshed gears can also lead to seizure of the gear train.

Seizure is the total movement stoppage of the gear train.

Unlike the belt and the chain drive, the driver and the driven gear move in different direction. To make the driver and the driven gear move in the same direction, another gear (called the IDLER) is inserted between the two (driver and the driven gear).

Types of gears

Spur gear: this has teeth parallel to the shaft of the gear.

Helical gear: this has teeth inclined to the shaft of the gear.

Worm gears: these are gears formed when a spur gear mesh with a screw.

Rack and pinion: these are gears that run on a flat toothed rack.

Planetary gears: these consist of a number of spur gear meshed with one another and another gear with internal gear.

Bevel gears: these are gears used when power is to be transmitted between inclined shafts

Uses of gear drive

To transmit motion between two inclined or parallel shafts.

To change direction of motion.

For speed selection .

Gear ratio

This can be defined as the ratio of the number of teeth on the driver gear to that on the driven gear

G=T[sub]1[/sub]/T[sub]2[/sub]

T[sub]1[/sub] is number of teeth on driver gear

T[sub]2[/sub] is number of teeth on driven gear

Speed ratio

This can be defined as the ratio of the speed of the driven gear to the speed of the driver gear.

S=S[sub]2[/sub]/S[sub]1[/sub]

S[sub]1[/sub] speed of the driver gear

S[sub]2[/sub] is speed of the driven gear

The gear ratio and the speed ratio of a gear train are equal. The speed of rotation of the driven gear depends on the number of teeth on the driven and the driver gear. Where a large increase in speed is desired (like in the case of motor car), a compound gear train is used.

Compound gear

The speed of the driven gear S[sub]2[/sub] is given as

S[sub]2[/sub] = S[sub]1[/sub] × T[sub]1[/sub]/T[sub]2[/sub]

Where each symbols has it usual meaning.

Changing the direction of drive,

Chain drives cannot be used for changing the direction of rotation of drives. Belt drive cannot be used to change direction of rotation of drive except when belt is crossed. Gears can be used for changing the direction of motion. The bevelled gear is often used for changing direction of motion between two perpendicular/inclined shafts.

EVALUATION

Which of these drives can be used to change the direction of rotation? (a) straight lap belt (b) chain drive (c) gear drive (d) none of the above

A gear with tooth parallel to the shaft is called ---(a) helical gear (b) planetary gear (c) worm gear (d) spur gear

The ratio of the speed of driver gear to the speed of the driven gear is --- (a) gear ratio (b) speed ratio (c) velocity ratio (d) none of the above

Answers

(c) 2. (d) 3. (d)

PERIOD TWO

CONTENT

CALCULATIONS ON GEAR AND SPEED RATIO

Question 1: the number of teeth on the driver and the driven gear is 12 and 16 respectively. If the speed of the driver gear is 100rev/min, calculate (i) the gear ratio (ii) speed of the driven gear

Question 2: A gear train is such that the number of teeth on the driver gear is 20 while that on the driven is 8. If the speed of the driver gear is 150rev/min. calculate the speed of the driven gear.

Question 4: A gear train has a gear ratio of 5/2 and a driven gear rotating at a speed of 180 revolution per minute. What would have been the speed of the driver gear?

Practical

Using hard cardboard gear of different radii and their centres with nail at different portion on a wood, the students should demonstrate the operation of compound gear.

Evaluation question

Which of these gears is a combination of a spur gear and a screw? (a) bevel gears (b) helical gear (c) spur gear (d) worm gear

A condition in which the movement of a gear system is halted due to a spoil is known as ---- (a) slip (b) seizure (c) reverse (d) bevel

The friction between the teeth of meshed gears can be reduced BY (a) avoiding the use of gear (b) exposing gear to air (c)Lubrication (d)aeration

The major use of drive is to (a) transmit motion (b) change direction of motion (c) reduce speed (d) avoid friction

The ratio of the number of teeth on the driven gear to the number of teeth on the driver gear is called (a) speed ratio (b) gear proportion (c) gear ratio (d) none of the above

The gear ratio of a gear train is [sup]7[/sup]/[sub]4[/sub] and the speed of the driver gear is 80rpm. What is the speed of the driven gear? (a) 70rpm (b) 140rpm (c) 150rpm (d) 210rpm

ASSIGNMENT

Consult your textbook and make a list of ten types of gear.

List five applications of the gear drives

READING ASSIGNMENT: Read your Basic Technology textbook by Olawehinmi, pages 160 - 169 and answer the following questions.

Define motion.

Write a short note on the following (i) linear motion (ii) rotary motion.

WEEK 3

TOPIC MOTION

CONTENT:

- Motion

- Linear motion

- Rotary motion

MOTION

This can be defined as the change in position of objects. This is a common phenomenon in nature. The moon moves, we human move from one place to another… . It is also a common practice for various component of a mechanical system to move relatively to one another; examples include : the needle of a sewing machine at work, the tyre of a moving car etc

Mechanical systems are commonly engaged in basically TWO types of motion.

1. Linear motion

2. Rotary motion

Linear motion:

This can be defined as change in position in a straight line. Like the motion of the needle of the sewing machine or motion of a crane being hauled up using a pulley. There are different types/parts of a mechanical system that exhibit this type of motion. They include;

1. Lever: It helps us to do work easily. Examples are the crowbar, the door knob etc. It often has a pivot (or a point of support) about which the lever turns. This point is called fulcrum. An example is a crowbar.

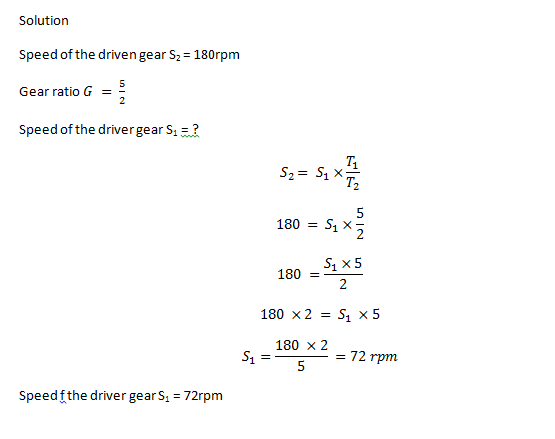

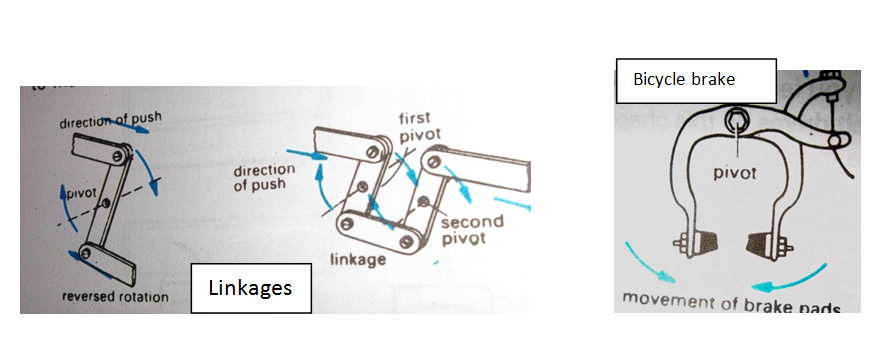

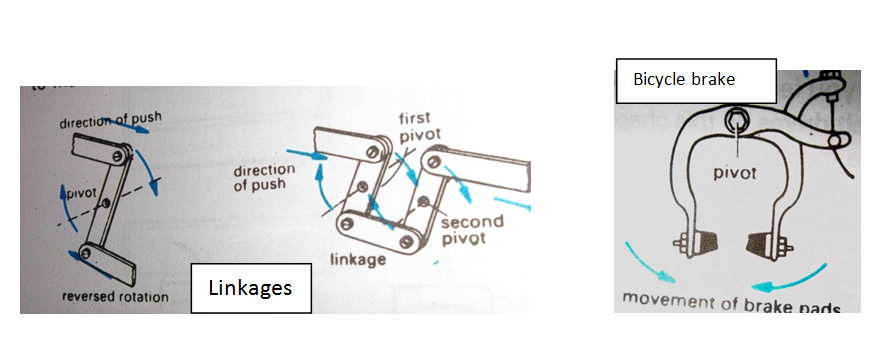

2. Linkages; this is an assembly of metallic bars in which each bar is connected to at least two other bars in an elbow/sliding joint. They are often used for converting linear motion to rotary motion and vice versa or for converting a linear motion to another linear motion but in the opposite direction. Application of linkage include, bicycle brake, crank and slide

Rotary motion:

This can be defined as change in position around fixed axis. Like the motion of the blade of a ceiling fan or the tyre of a moving car. There are two types of rotary motion:

i. One way rotary motion: This allows continuous rotation and can only be brought to rest by the application of a brake. Examples include the clock mechanism, the circular mechanical saws for cutting wood, shaft of cars… .

Note that in some of these motions, reversibility may be required ( e.g shaft of a moving car, trains or crane) while for others reversibility may be dangerous and need to be prohibited (e.g circular saw for cutting wood, clock mechanism) and their motions can be controlled by the ratchet wheel

ii. Non return rotary motion: This allows intermittent rotation but only in one direction. i.e the motion can stop and continue at intervals in the same direction.

EVALUATION

I. State one difference between the one-way rotary motion and the non-return rotary motion.

II. Mention three mechanical systems in linear motion.

III. List some applications of the linkage system.

Sub topic 2

- Control of rotary motion

- Conversion of rotary to linear motion

Control of rotary motion

This involves the use of devices for initiating and arresting the flow of motion. These devices include;

1. Brakes

2. Clutch

3. Ratchet

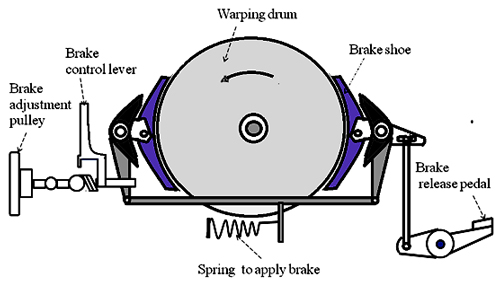

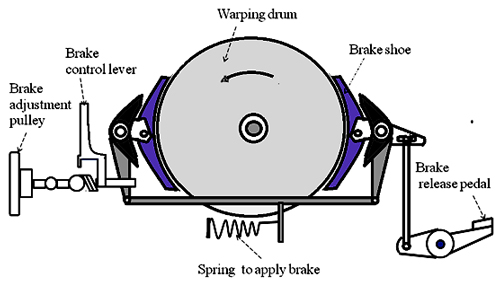

Brakes; These are devices used to slow down or bring to a complete stop a moving body. Brakes are used for removing kinetic energy form moving bodies. There are different types of brakes

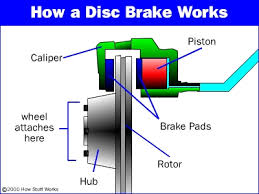

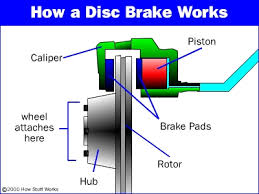

i. Disc brake; used for light vehicles

ii. Drum brakes; used for heavy vehicles

iii. External block brakes; used for cranes and winches

iv. Internal shoe brake; used for motorcycles and other small automobiles.

Disc brake

Drum brake

External block brakes

Internal shoe brake

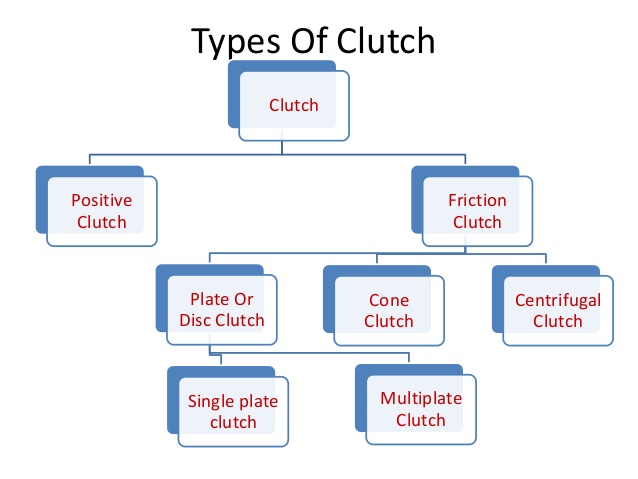

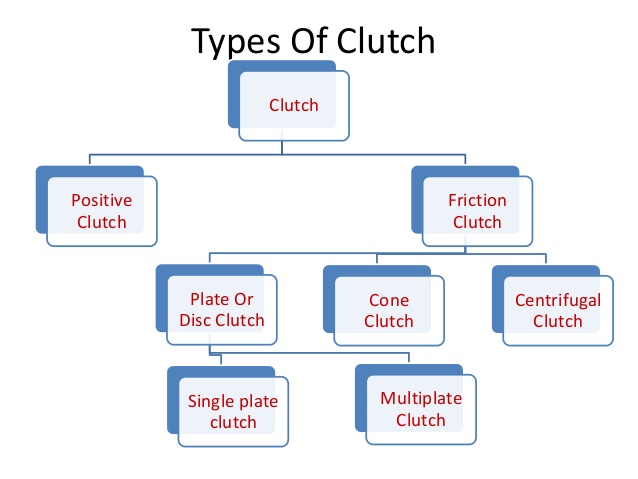

Clutches; these are devices used for connecting and disconnecting two moving parts. Types of clutches include;

i. Friction clutch

ii. Dog clutch

Conversion of rotary to linear motion.

The following devices are used in the conversion of rotary motion to linear motion and vice versa;

1. Rack and pinion (e.g kerosene stove, kerosene lantern)

2. Crank and slider

3. Bench vice

4. G-clamp

5. Screw jack

6. Connecting rod and piston (motorcycles)

7. Reverse linkage and the push – pull linkage

Ratchet

These are devices that transmit motion intermittently or allow motion only in one direction.

Evaluation

1. Which of these devices is used for removing the kinetic energy in moving bodies? (a) clutch (b) brake (c) linkage (d) ratchet

2. --- is a type of motion along a straight line. (a) linear motion (b) rotary motion (c) random motion (d) relative motion

3. Which of these brakes is suitable for heavy vehicles? (a) internal shoe brake (b) disc brakes (c) drum brake system (d) external shoe brake.

4. --- is applied in raising the oil wick of kerosene stove. (a) rack and pinion (b) cranks and piston (c) cranks and connecting rods (d) screw

ASSIGNMENT

1. Making a list of three mechanism that applies the following

i. Rack and pinion

ii. Crank and connecting rod (piston)

READING ASSIGNMENT

Read your Basic Technology textbook written by Olawehinmi and answer the following questions:

1. Write a short note on each of the following

i. Aerodynamics

ii. Streamlined bodies

iii. Pneumatics

CONTENT:

- Motion

- Linear motion

- Rotary motion

MOTION

This can be defined as the change in position of objects. This is a common phenomenon in nature. The moon moves, we human move from one place to another… . It is also a common practice for various component of a mechanical system to move relatively to one another; examples include : the needle of a sewing machine at work, the tyre of a moving car etc

Mechanical systems are commonly engaged in basically TWO types of motion.

1. Linear motion

2. Rotary motion

Linear motion:

This can be defined as change in position in a straight line. Like the motion of the needle of the sewing machine or motion of a crane being hauled up using a pulley. There are different types/parts of a mechanical system that exhibit this type of motion. They include;

1. Lever: It helps us to do work easily. Examples are the crowbar, the door knob etc. It often has a pivot (or a point of support) about which the lever turns. This point is called fulcrum. An example is a crowbar.

2. Linkages; this is an assembly of metallic bars in which each bar is connected to at least two other bars in an elbow/sliding joint. They are often used for converting linear motion to rotary motion and vice versa or for converting a linear motion to another linear motion but in the opposite direction. Application of linkage include, bicycle brake, crank and slide

Rotary motion:

This can be defined as change in position around fixed axis. Like the motion of the blade of a ceiling fan or the tyre of a moving car. There are two types of rotary motion:

i. One way rotary motion: This allows continuous rotation and can only be brought to rest by the application of a brake. Examples include the clock mechanism, the circular mechanical saws for cutting wood, shaft of cars… .

Note that in some of these motions, reversibility may be required ( e.g shaft of a moving car, trains or crane) while for others reversibility may be dangerous and need to be prohibited (e.g circular saw for cutting wood, clock mechanism) and their motions can be controlled by the ratchet wheel

ii. Non return rotary motion: This allows intermittent rotation but only in one direction. i.e the motion can stop and continue at intervals in the same direction.

EVALUATION

I. State one difference between the one-way rotary motion and the non-return rotary motion.

II. Mention three mechanical systems in linear motion.

III. List some applications of the linkage system.

Sub topic 2

- Control of rotary motion

- Conversion of rotary to linear motion

Control of rotary motion

This involves the use of devices for initiating and arresting the flow of motion. These devices include;

1. Brakes

2. Clutch

3. Ratchet

Brakes; These are devices used to slow down or bring to a complete stop a moving body. Brakes are used for removing kinetic energy form moving bodies. There are different types of brakes

i. Disc brake; used for light vehicles

ii. Drum brakes; used for heavy vehicles

iii. External block brakes; used for cranes and winches

iv. Internal shoe brake; used for motorcycles and other small automobiles.

Disc brake

Drum brake

External block brakes

Internal shoe brake

Clutches; these are devices used for connecting and disconnecting two moving parts. Types of clutches include;

i. Friction clutch

ii. Dog clutch

Conversion of rotary to linear motion.

The following devices are used in the conversion of rotary motion to linear motion and vice versa;

1. Rack and pinion (e.g kerosene stove, kerosene lantern)

2. Crank and slider

3. Bench vice

4. G-clamp

5. Screw jack

6. Connecting rod and piston (motorcycles)

7. Reverse linkage and the push – pull linkage

Ratchet

These are devices that transmit motion intermittently or allow motion only in one direction.

Evaluation

1. Which of these devices is used for removing the kinetic energy in moving bodies? (a) clutch (b) brake (c) linkage (d) ratchet

2. --- is a type of motion along a straight line. (a) linear motion (b) rotary motion (c) random motion (d) relative motion

3. Which of these brakes is suitable for heavy vehicles? (a) internal shoe brake (b) disc brakes (c) drum brake system (d) external shoe brake.

4. --- is applied in raising the oil wick of kerosene stove. (a) rack and pinion (b) cranks and piston (c) cranks and connecting rods (d) screw

ASSIGNMENT

1. Making a list of three mechanism that applies the following

i. Rack and pinion

ii. Crank and connecting rod (piston)

READING ASSIGNMENT

Read your Basic Technology textbook written by Olawehinmi and answer the following questions:

1. Write a short note on each of the following

i. Aerodynamics

ii. Streamlined bodies

iii. Pneumatics

WEEK 4

TOPIC: AIR FLOW

CONTENT

- Air flow

- Bernoulli’s principle

- Aerodynamics

Air flow

This refers to air molecules in motion. Flow is an exclusive property of all fluids (liquids and gases). However unlike liquids, air does not necessarily need a channel or container for it to flow. Breeze/wind is formed when molecules of air are set in motion. Molecules of air can be set in motion by any of the following processes:

i. Blowing air

ii. Using the bellows (often used by blacksmith)

iii. Using pumps

iv. Using fan

When liquids flow through channels, agents such as gravity or a mechanical device is necessary to sustain the flow. Liquid (water) flow could either be laminar (streamline) or turbulent.

In laminar flow, all the portions of the water move gently in a path parallel to the confining channel.

Turbulent flow is a force flow; water particles do not move in a straight line. An example of this is the water flow in drainage during a heavy downpour.

Moving air molecules possess energy. This energy can be applied in the following processes;

- Action of the wind mill

- Movement of flag attached to flag pole.

- Destructive action of the hurricane

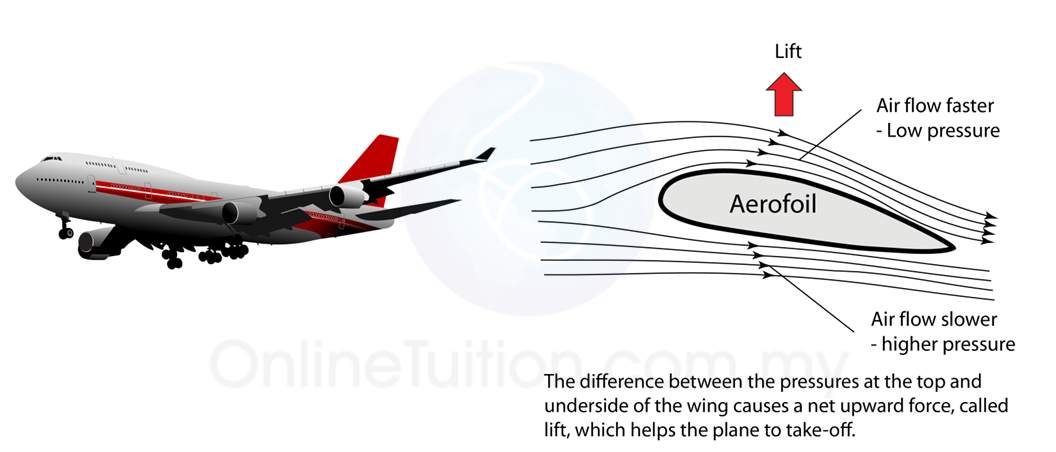

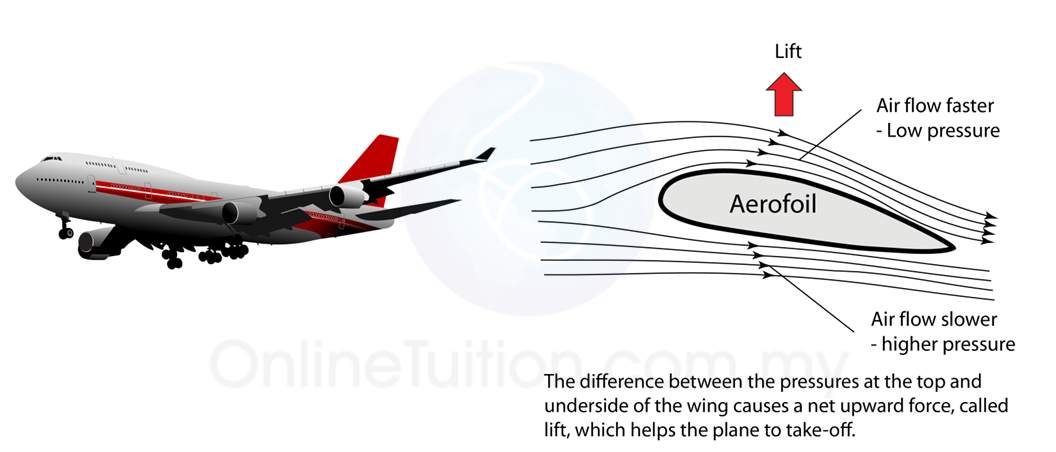

When air moves over the surface of an object at high speed, the pressure on the surface is greatly reduced (i.e the faster air molecules move over a surface the lesser the pressure acting on the surface). This principle is called the Bernoulli’s principle. This principle is used for explaining the lift force experienced by helicopters and aeroplanes when they are in air. To demonstrate this principle, you may try blowing air between two papers; you’ll observe that the papers move toward each other instead of going apart. This is because increase in the speed of air between the papers result in decrease in the pressure between the papers.

A science that studies the force on object moving through air is called Aerodynamics.

Aeroplanes’ wings are designed to have a streamline shape which allows the air above it to move faster than the air under it. The pressure under the aeroplane is therefore greater than that above the aeroplane thereby resulting in net pressure acting under the aeroplane as well as a lift force on the plane. The streamline shape of the aircraft also minimizes the frictional drag force opposing the motion of the plane.

The drag force acts on the aeroplane in a direction perpendicular to the lift force. Summarily, four forces act on a body moving through air:

i. The weight(W) of the body which act downward

ii. The lift force(L) which act upward

iii. The drag force(D) which opposes the motion of the bodies

iv. The thrust(T) of body itself moving it forward

Other applications of the Bernoulli’s principle include;

I. Balloon

II. Kite

Evaluation

1. state the Bernoulli’s principle

2. List the types of water flow.

SUB TOPIC 2: PNEUMATIC DEVICES

CONTENTS:

- Water wheel

- Turbines

- Air compressor

- Hydraulic lift

- Water sprinkler

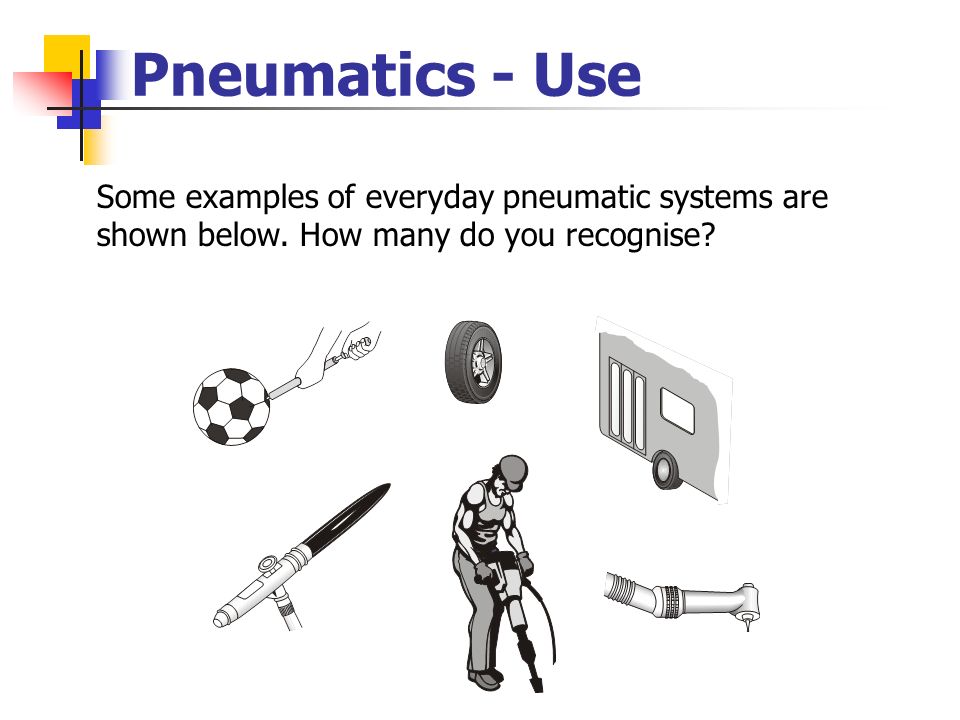

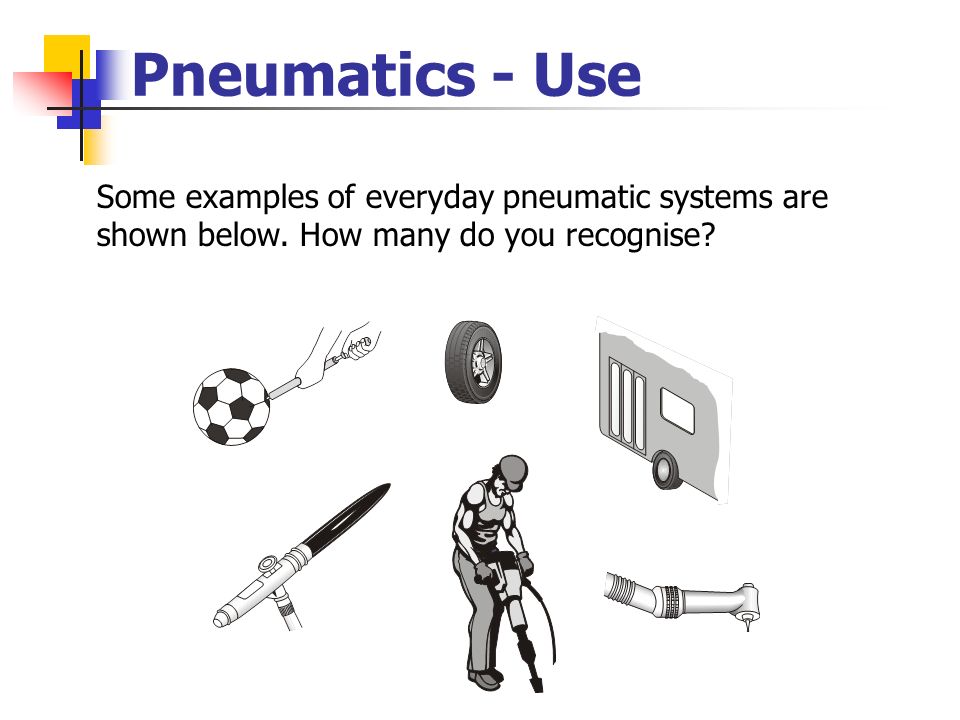

Pneumatic devices.

These are devices that use compressed air to do useful work. Some of these devices also use liquids to transmit energy. They include:

i. Pumps and turbines

ii. Air hammer

iii. Compression pump

iv. Garden sprinkler

v. Water wheel

vi. Hydraulic jack

vii. Paint sprayer

Water wheel

This is a simple mechanical device which converts water power into rotary motion. It is sometimes also called gravity wheel. Falling water is used to turn the axle of the water wheel.

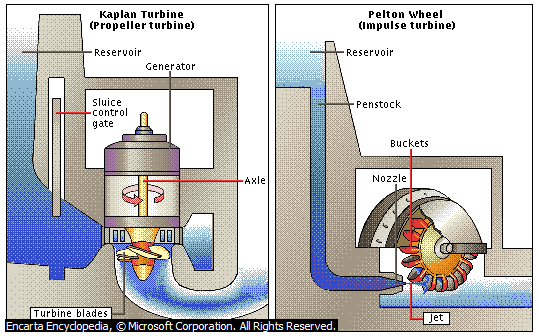

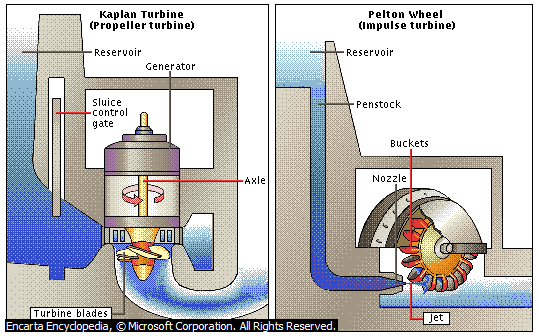

Turbines

This is a rotary machine which converts the energy of moving water, steam or hot gas into mechanical energy.

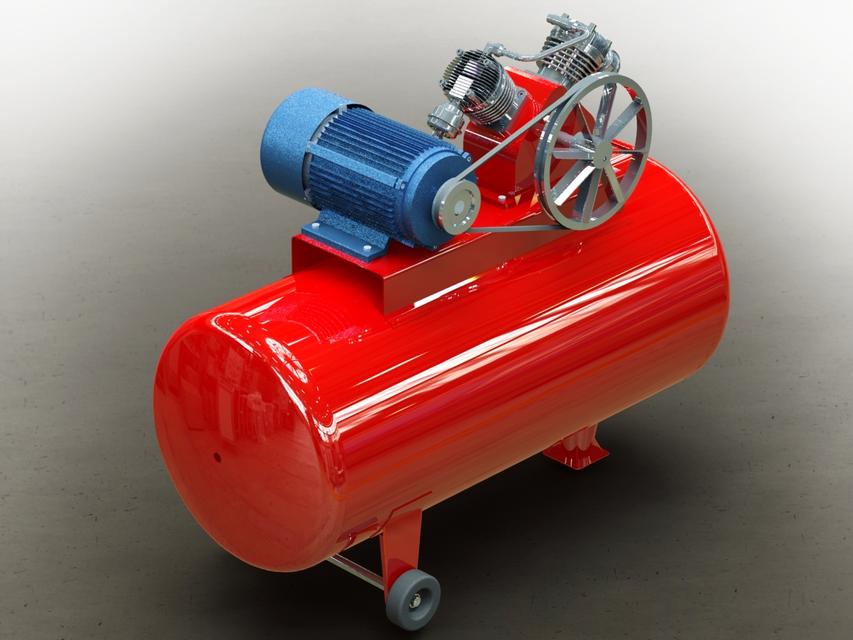

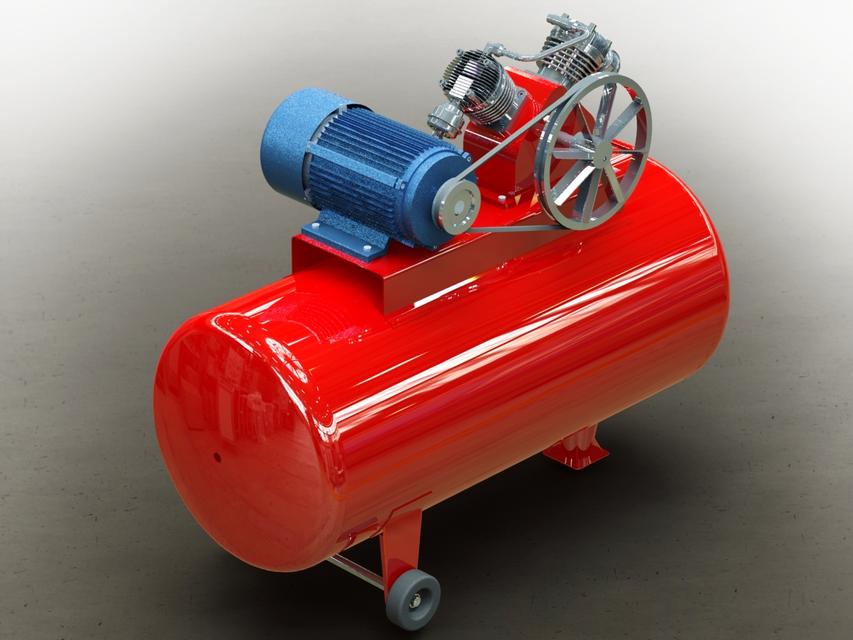

Air Compressor

Air Compressor, also air pump is a machine that decreases the volume and increases the pressure of a quantity of air by mechanical means. Air thus compressed possesses great potential energy, because when the external pressure is removed, the air expands rapidly. The controlled expansive force of compressed air is used in many ways and provides the motive force for air motors and tools, including pneumatic hammer, air drills, sandblasting machines, and paint sprayers.

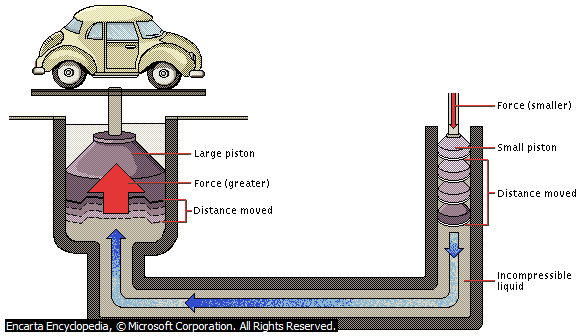

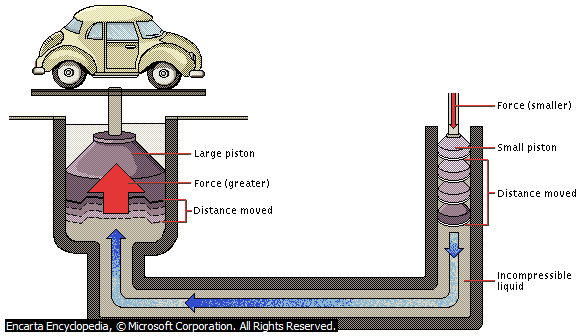

Hydraulic lift

This applies the Pascal’s principle of transmissibility of pressure to generate a huge force by applying a small effort.

A small force can be used to lift a heavy car using the hydraulic lift. Many other hydraulic systems (e.g hydraulic press, hydraulic water pump, hydraulic jack…) also apply this principle.

Garden sprinkler

This applies the Newton’s third law of motion which states that for every action there is an equal but opposing reaction. When water is ejected from the nozzle of the sprinkler, the forward thrust of the water result in a backward push on the nozzle thereby making the sprinkler turn about it axis watering several portion of the garden and not just on a single spot.

EVALUATION

1. What are pneumatic devices?

2. Mention five types of pneumatic device.

CONTENT

- Air flow

- Bernoulli’s principle

- Aerodynamics

Air flow

This refers to air molecules in motion. Flow is an exclusive property of all fluids (liquids and gases). However unlike liquids, air does not necessarily need a channel or container for it to flow. Breeze/wind is formed when molecules of air are set in motion. Molecules of air can be set in motion by any of the following processes:

i. Blowing air

ii. Using the bellows (often used by blacksmith)

iii. Using pumps

iv. Using fan

When liquids flow through channels, agents such as gravity or a mechanical device is necessary to sustain the flow. Liquid (water) flow could either be laminar (streamline) or turbulent.

In laminar flow, all the portions of the water move gently in a path parallel to the confining channel.

Turbulent flow is a force flow; water particles do not move in a straight line. An example of this is the water flow in drainage during a heavy downpour.

Moving air molecules possess energy. This energy can be applied in the following processes;

- Action of the wind mill

- Movement of flag attached to flag pole.

- Destructive action of the hurricane

When air moves over the surface of an object at high speed, the pressure on the surface is greatly reduced (i.e the faster air molecules move over a surface the lesser the pressure acting on the surface). This principle is called the Bernoulli’s principle. This principle is used for explaining the lift force experienced by helicopters and aeroplanes when they are in air. To demonstrate this principle, you may try blowing air between two papers; you’ll observe that the papers move toward each other instead of going apart. This is because increase in the speed of air between the papers result in decrease in the pressure between the papers.

A science that studies the force on object moving through air is called Aerodynamics.

Aeroplanes’ wings are designed to have a streamline shape which allows the air above it to move faster than the air under it. The pressure under the aeroplane is therefore greater than that above the aeroplane thereby resulting in net pressure acting under the aeroplane as well as a lift force on the plane. The streamline shape of the aircraft also minimizes the frictional drag force opposing the motion of the plane.

The drag force acts on the aeroplane in a direction perpendicular to the lift force. Summarily, four forces act on a body moving through air:

i. The weight(W) of the body which act downward

ii. The lift force(L) which act upward

iii. The drag force(D) which opposes the motion of the bodies

iv. The thrust(T) of body itself moving it forward

Other applications of the Bernoulli’s principle include;

I. Balloon

II. Kite

Evaluation

1. state the Bernoulli’s principle

2. List the types of water flow.

SUB TOPIC 2: PNEUMATIC DEVICES

CONTENTS:

- Water wheel

- Turbines

- Air compressor

- Hydraulic lift

- Water sprinkler

Pneumatic devices.

These are devices that use compressed air to do useful work. Some of these devices also use liquids to transmit energy. They include:

i. Pumps and turbines

ii. Air hammer

iii. Compression pump

iv. Garden sprinkler

v. Water wheel

vi. Hydraulic jack

vii. Paint sprayer

Water wheel

This is a simple mechanical device which converts water power into rotary motion. It is sometimes also called gravity wheel. Falling water is used to turn the axle of the water wheel.

Turbines

This is a rotary machine which converts the energy of moving water, steam or hot gas into mechanical energy.

Air Compressor

Air Compressor, also air pump is a machine that decreases the volume and increases the pressure of a quantity of air by mechanical means. Air thus compressed possesses great potential energy, because when the external pressure is removed, the air expands rapidly. The controlled expansive force of compressed air is used in many ways and provides the motive force for air motors and tools, including pneumatic hammer, air drills, sandblasting machines, and paint sprayers.

Hydraulic lift

This applies the Pascal’s principle of transmissibility of pressure to generate a huge force by applying a small effort.

A small force can be used to lift a heavy car using the hydraulic lift. Many other hydraulic systems (e.g hydraulic press, hydraulic water pump, hydraulic jack…) also apply this principle.

Garden sprinkler

This applies the Newton’s third law of motion which states that for every action there is an equal but opposing reaction. When water is ejected from the nozzle of the sprinkler, the forward thrust of the water result in a backward push on the nozzle thereby making the sprinkler turn about it axis watering several portion of the garden and not just on a single spot.

EVALUATION

1. What are pneumatic devices?

2. Mention five types of pneumatic device.

WEEK 5

TOPIC: SIMPLE ELECTRICAL WIRING

SUB-TOPICS: ELECTRICAL CIRCUIT

• Meaning of electrical circuit and types

• Wiring tools and materials

Sub-Topic 1: Meaning of electrical circuit and types.

An electric circuit is a system that consists of the load, source of electricity, the key or switch and the connecting wires.

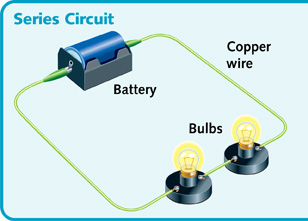

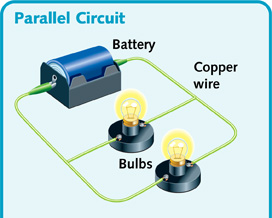

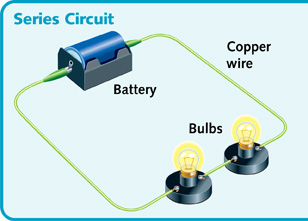

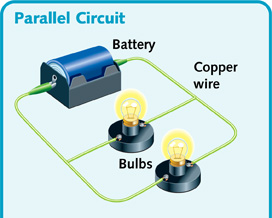

There are two types of electrical circuits (i) Series circuit (ii) parallel circuit.

Series circuit: In this arrangement, the load(resistors) are connected end to end. The same current flows through all appliances. If one stops functioning, the others stop.

Parallel circuit: In this arrangement, the load(resistors) are connected side by side in parallel order. The same voltage is used. A fault which may occur in one electrical path will not affect the others.

Evaluation

• What is Electrical circuit?

• Differentiate between series circuit and parallel circuit.

Wiring tools and materials.

Electrical wiring is an arrangement whereby electrical loads are connected to the mains supply. A good wiring protects the user from electric shock and prevents fire outbreak.

Wiring tools are tools used for wiring and installation of circuits in homes, offices and other building structures and equipment.

Wiring tool ------ Uses

Pliers------Used for cutting cables and twisting together wire ends

Screw driver ------Used for tightening screws to wooden blocks and fixing electrical accessories in position

Clips------ They are used to fasten electrical cables to the wall or ceiling.

Hammer ------ It is used to drive nails through clips into the wall.

Mallet------ It is used to straighten out hunches in wires during surface wiring.

Drilling machine------ It is an electrically power machine used for making holes in walls or wooden blocks.

Screws and nails------They are used to hold the cable and electrical accessories in position.

Tester ------It is used to check where live current flows in the circuit.

Cable------It is the insulated wire that provides electrical connection between the electrical load and the supply point.

Electrical accessories are devices other than lighting fittings associated with the wiring and current utilizing appliances of an installation. Accessories are rated for the maximum voltage or current they are designed to withstand without undue over-heating or failure. These include switches, lamp holders, ceiling roses, joint boxes, fuse boxes, socket plugs, connectors, adaptors etc.

Switches: These are used to control the flow of current through a particular point.

Lamp holders: They are used to hold light bulbs when fixed to the ceiling or wall.

Wall socket and plugs: They are located on the walls for the drawing of current by appliances

Evaluation

1. Mention four tools used in electrical wiring and their uses.

2. Mention three electrical accessories and their uses.

Assignment

Draw four wiring tools and three electrical accessories.

Reading Assignment

Read about Simple Electrical wiring, NERDC Basic Technology for Junior Secondary School 3.

SUB-TOPICS: ELECTRICAL CIRCUIT

• Meaning of electrical circuit and types

• Wiring tools and materials

Sub-Topic 1: Meaning of electrical circuit and types.

An electric circuit is a system that consists of the load, source of electricity, the key or switch and the connecting wires.

There are two types of electrical circuits (i) Series circuit (ii) parallel circuit.

Series circuit: In this arrangement, the load(resistors) are connected end to end. The same current flows through all appliances. If one stops functioning, the others stop.

Parallel circuit: In this arrangement, the load(resistors) are connected side by side in parallel order. The same voltage is used. A fault which may occur in one electrical path will not affect the others.

Evaluation

• What is Electrical circuit?

• Differentiate between series circuit and parallel circuit.

Wiring tools and materials.

Electrical wiring is an arrangement whereby electrical loads are connected to the mains supply. A good wiring protects the user from electric shock and prevents fire outbreak.

Wiring tools are tools used for wiring and installation of circuits in homes, offices and other building structures and equipment.

Wiring tool ------ Uses

Pliers------Used for cutting cables and twisting together wire ends

Screw driver ------Used for tightening screws to wooden blocks and fixing electrical accessories in position

Clips------ They are used to fasten electrical cables to the wall or ceiling.

Hammer ------ It is used to drive nails through clips into the wall.

Mallet------ It is used to straighten out hunches in wires during surface wiring.

Drilling machine------ It is an electrically power machine used for making holes in walls or wooden blocks.

Screws and nails------They are used to hold the cable and electrical accessories in position.

Tester ------It is used to check where live current flows in the circuit.

Cable------It is the insulated wire that provides electrical connection between the electrical load and the supply point.

Electrical accessories are devices other than lighting fittings associated with the wiring and current utilizing appliances of an installation. Accessories are rated for the maximum voltage or current they are designed to withstand without undue over-heating or failure. These include switches, lamp holders, ceiling roses, joint boxes, fuse boxes, socket plugs, connectors, adaptors etc.

Switches: These are used to control the flow of current through a particular point.

Lamp holders: They are used to hold light bulbs when fixed to the ceiling or wall.

Wall socket and plugs: They are located on the walls for the drawing of current by appliances

Evaluation

1. Mention four tools used in electrical wiring and their uses.

2. Mention three electrical accessories and their uses.

Assignment

Draw four wiring tools and three electrical accessories.

Reading Assignment

Read about Simple Electrical wiring, NERDC Basic Technology for Junior Secondary School 3.

WEEK 6

TOPIC: BUILDING

SUB-TOPICS:

• Definition and function of foundation

• Types and materials for making walls

sub-Topic I: Definition and function of foundation

Foundation.

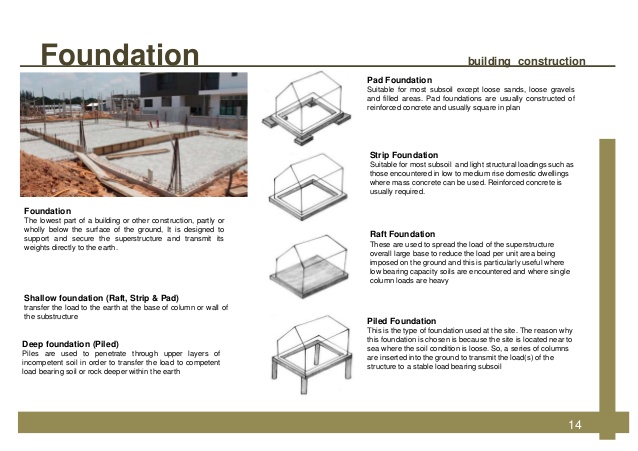

The term foundation is the expanded base of a column in addition to the ground or sub-soil which supports the base. The ground or sub soil on which the building stands is the natural foundation, while the expanded base which is constructed of concrete or masonry materials like rocks, stones, bricks is called artificial foundation. The choice of foundation depends on the type of building to be constructed, the load imposed on the building and the type and nature of the soil.

Functions of foundation:

1. To receive the weight of the building.

2. To distribute the weight of the building to the ground effectively.

3. To hold the building firmly to the ground against external forces like wind, storms.

4. To transmit the weight of the building to the sub-soil or ground.

5. To sustain the dead load of the building.

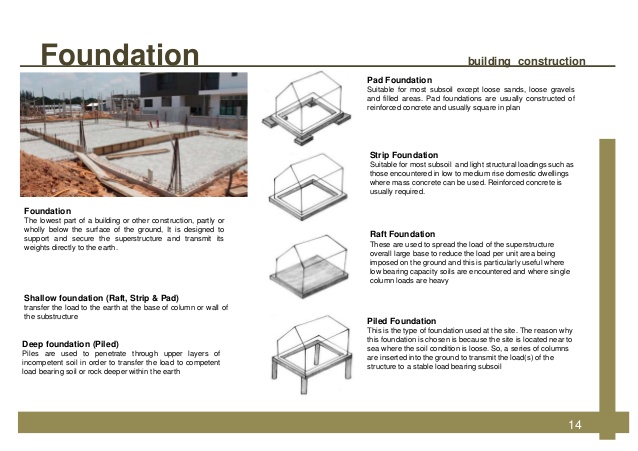

Types of foundation:

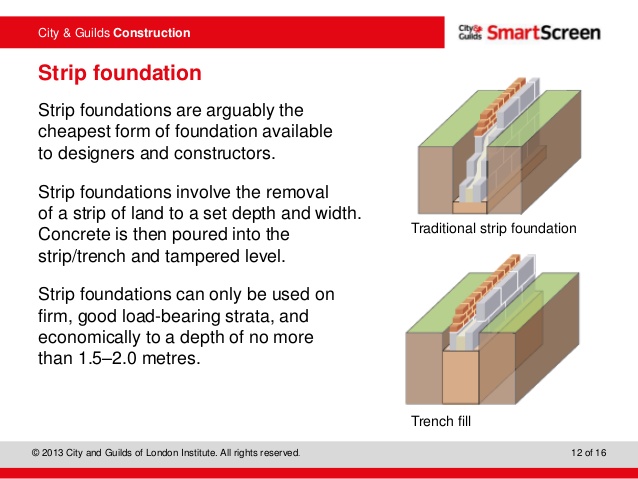

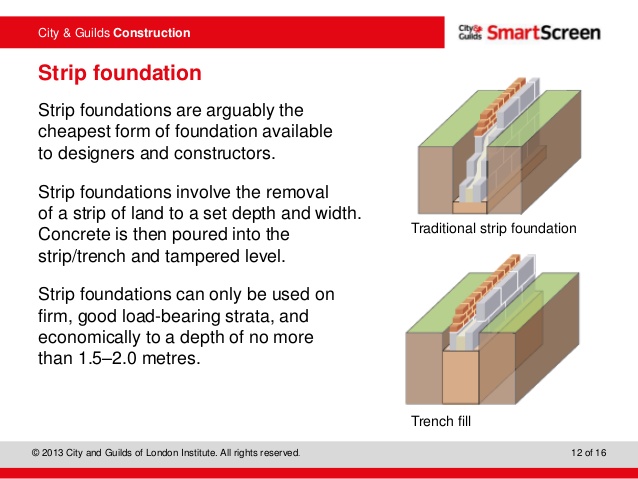

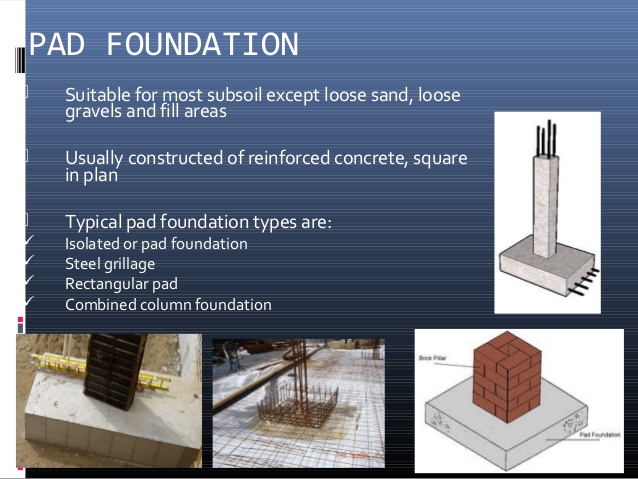

1. Strip foundation: This consists of a continuous strip of concrete laid on the trench after excavation. It is usually 225mm thick and used for bungalows, fences etc and on a moderately hard soil.

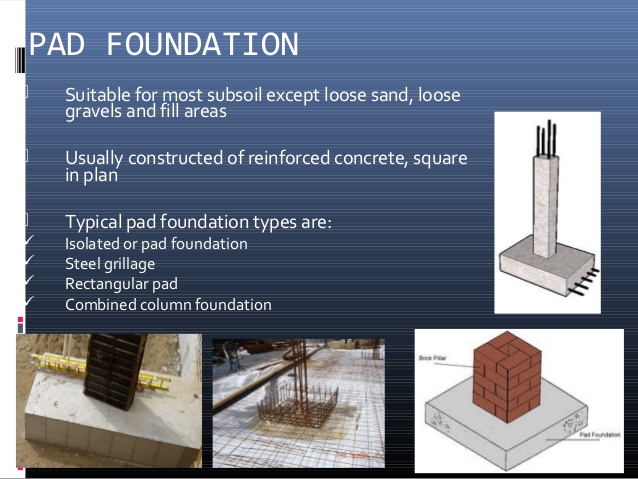

2. Pad foundation: This type of foundation is an isolated foundation used to support columns. The size of the pad foundation could be reduced by providing steel reinforcement towards the bottom of the foundation running in both directions. It is used for storey building.

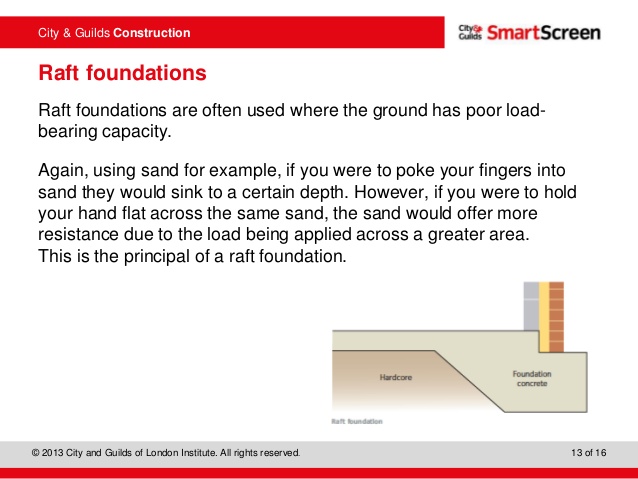

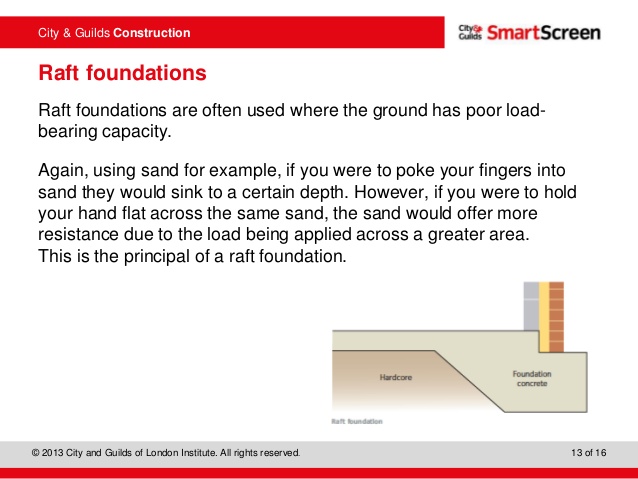

3. Raft foundation: This is used where the load bearing capacity of the soil is weak. It is used on sandy, swampy or marshy ground. It consists of reinforcement slab up to 300mm thick. It covers the whole area of the building and usually extends beyond it.

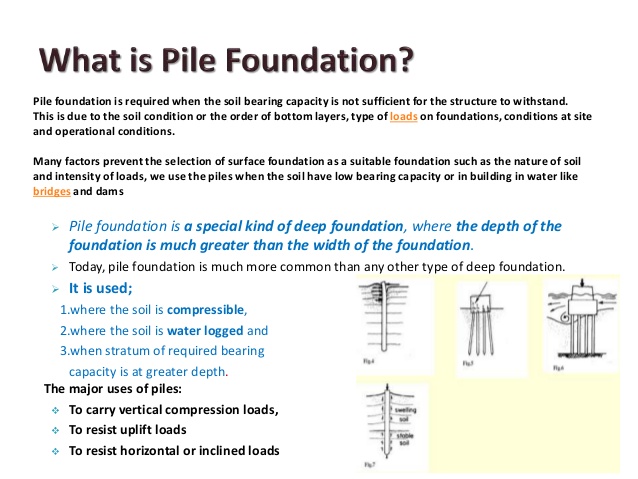

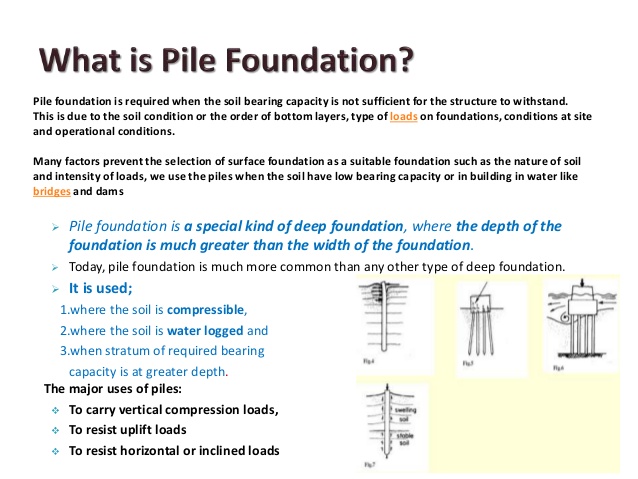

4. Piled foundation: This is used for multistory buildings, for supports in bridges and water logged areas to support the structures. The imposed load is transmitted to suitable materials in a lower stratum by the use of piles.

TYPES OF SOIL AND THEIR PROPERTIES

S/N TYPE OF SOIL PROPERTIES

1 Sand The particles are gritly to finger, loose, easily break when dry

2 Clay Easily moulded, brittle and tough when dry, sticky when wet.

3 Gravel It is loose, easily removed by shovel and homogenous

4 Silt Dries quickly, moderately plastic, soft and firm, homogenous

Excavation for foundation: This is the process of digging the ground to the required depth not less than 750mm. There are two basic methods of excavation.

1. Manual method: This involves the use of digger, shovel, wheelbarrow

2. Mechanical method: This involves the use of mechanically operated machine e.g excavation tractor, mechanical shovel, ditcher etc

EVALUATION

1. What is foundation?

2. Mention three reasons why it is necessary to construct foundation.

3. Under what conditions are the different types of foundation used?

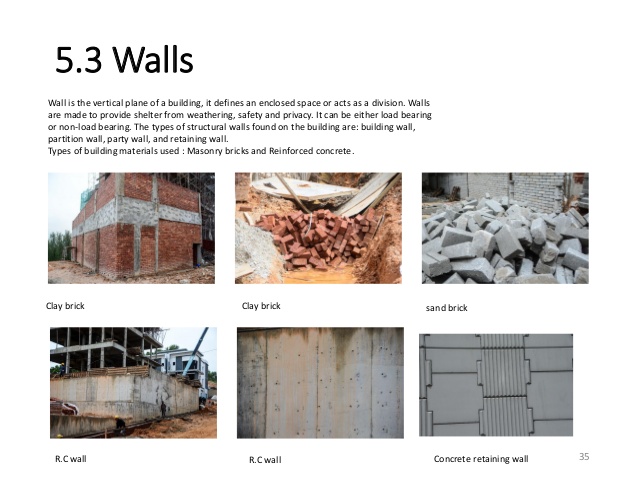

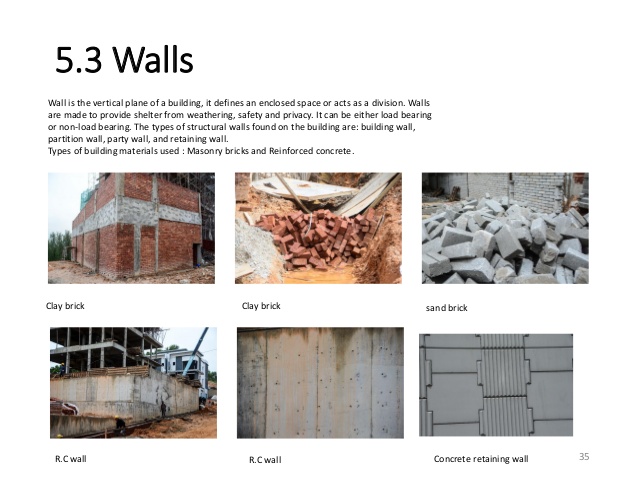

Sub-Topic II: Types and materials for making walls.

Wall: It is a structural member in building(450mm) used mainly for the enclosure or division of a space within a building. It can be external wall or load bearing wall built right from the foundation to the roof level, it carries the weight of itself and some other elements e.g roof.

It can be internal cross walls, they are the non-load bearing wall (150mm), it carries only the weight of itself.

Function of a wall:

i. To carry the load and other elements in the building structure.

ii. To divide a space as partition and as a compartment wall.

iii. To protect the structure against weather.

iv. For privacy

v. For security purpose

Walling Materials: They include stone, clay and mud, Timber, Bricks, sand creates blocks etc.

Types of walls: There are many types of walls, depending on the materials used and the method of construction.

i. Block wall ii. Partition wall iii. Sleeper wall iv. Timber wall v. Foundation wall vi. Glass wall vii. Retaining wall viii. Cavity wall ix. Reinforced concrete walls x. Stone wall xi. Bamboo wall xii. Clay or mud wall xiii. Masonry wall.

WALL FINISHES: They are materials used to protect the surface of a wall from weather element. The common wall finishing are Plastering, rendering and painting.

Plastering: This is the type of finishing that is given to the internal wall of a building. Cement and sand are mixed with water in ratio 1:3 with the help of hand Trowel. Two or three layers of plastering are recommended on the surface of a masonry wall.

Rendering: This is the type of finishing that is given to the external wall of a building. This can be done using

i. Mixture of cement, sand and water and applied to the surface of the wall with hand trowel.

ii. Pebble dash: This is done by throwing about 10mm size of gravel on the surface of the external wall.

iii. Spattered dash finish: This is done by spraying about ratio 1:6 (cement and sand ratio) mixture containing colored pigment on the surface of the wall.

Painting: This is a liquid coating applied on the surface of a building wall for the purpose of decoration and protection from the elements of weather.

BONDING: This refers to the arrangement of bricks or blocks in a way that a brick or block rests on at least 2 others so that continuous vertical joint which reduces strength and stability in walls is eliminated.

EVALUATION:

• Mention three functions of a wall.

• Mention four materials for walling

• List five types of wall.

ASSIGNMENT:

Within your locality get the different types of soil.

READING ASSIGNMENT:

The students should read about Building foundation NERDC Basic Technology for Junior Secondary School 3

SUB-TOPICS:

• Definition and function of foundation

• Types and materials for making walls

sub-Topic I: Definition and function of foundation

Foundation.

The term foundation is the expanded base of a column in addition to the ground or sub-soil which supports the base. The ground or sub soil on which the building stands is the natural foundation, while the expanded base which is constructed of concrete or masonry materials like rocks, stones, bricks is called artificial foundation. The choice of foundation depends on the type of building to be constructed, the load imposed on the building and the type and nature of the soil.

Functions of foundation:

1. To receive the weight of the building.

2. To distribute the weight of the building to the ground effectively.

3. To hold the building firmly to the ground against external forces like wind, storms.

4. To transmit the weight of the building to the sub-soil or ground.

5. To sustain the dead load of the building.

Types of foundation:

1. Strip foundation: This consists of a continuous strip of concrete laid on the trench after excavation. It is usually 225mm thick and used for bungalows, fences etc and on a moderately hard soil.

2. Pad foundation: This type of foundation is an isolated foundation used to support columns. The size of the pad foundation could be reduced by providing steel reinforcement towards the bottom of the foundation running in both directions. It is used for storey building.

3. Raft foundation: This is used where the load bearing capacity of the soil is weak. It is used on sandy, swampy or marshy ground. It consists of reinforcement slab up to 300mm thick. It covers the whole area of the building and usually extends beyond it.

4. Piled foundation: This is used for multistory buildings, for supports in bridges and water logged areas to support the structures. The imposed load is transmitted to suitable materials in a lower stratum by the use of piles.

TYPES OF SOIL AND THEIR PROPERTIES

S/N TYPE OF SOIL PROPERTIES

1 Sand The particles are gritly to finger, loose, easily break when dry

2 Clay Easily moulded, brittle and tough when dry, sticky when wet.

3 Gravel It is loose, easily removed by shovel and homogenous

4 Silt Dries quickly, moderately plastic, soft and firm, homogenous

Excavation for foundation: This is the process of digging the ground to the required depth not less than 750mm. There are two basic methods of excavation.

1. Manual method: This involves the use of digger, shovel, wheelbarrow

2. Mechanical method: This involves the use of mechanically operated machine e.g excavation tractor, mechanical shovel, ditcher etc

EVALUATION

1. What is foundation?

2. Mention three reasons why it is necessary to construct foundation.

3. Under what conditions are the different types of foundation used?

Sub-Topic II: Types and materials for making walls.

Wall: It is a structural member in building(450mm) used mainly for the enclosure or division of a space within a building. It can be external wall or load bearing wall built right from the foundation to the roof level, it carries the weight of itself and some other elements e.g roof.

It can be internal cross walls, they are the non-load bearing wall (150mm), it carries only the weight of itself.

Function of a wall:

i. To carry the load and other elements in the building structure.

ii. To divide a space as partition and as a compartment wall.

iii. To protect the structure against weather.

iv. For privacy

v. For security purpose

Walling Materials: They include stone, clay and mud, Timber, Bricks, sand creates blocks etc.

Types of walls: There are many types of walls, depending on the materials used and the method of construction.

i. Block wall ii. Partition wall iii. Sleeper wall iv. Timber wall v. Foundation wall vi. Glass wall vii. Retaining wall viii. Cavity wall ix. Reinforced concrete walls x. Stone wall xi. Bamboo wall xii. Clay or mud wall xiii. Masonry wall.

WALL FINISHES: They are materials used to protect the surface of a wall from weather element. The common wall finishing are Plastering, rendering and painting.

Plastering: This is the type of finishing that is given to the internal wall of a building. Cement and sand are mixed with water in ratio 1:3 with the help of hand Trowel. Two or three layers of plastering are recommended on the surface of a masonry wall.

Rendering: This is the type of finishing that is given to the external wall of a building. This can be done using

i. Mixture of cement, sand and water and applied to the surface of the wall with hand trowel.

ii. Pebble dash: This is done by throwing about 10mm size of gravel on the surface of the external wall.

iii. Spattered dash finish: This is done by spraying about ratio 1:6 (cement and sand ratio) mixture containing colored pigment on the surface of the wall.

Painting: This is a liquid coating applied on the surface of a building wall for the purpose of decoration and protection from the elements of weather.

BONDING: This refers to the arrangement of bricks or blocks in a way that a brick or block rests on at least 2 others so that continuous vertical joint which reduces strength and stability in walls is eliminated.

EVALUATION:

• Mention three functions of a wall.

• Mention four materials for walling

• List five types of wall.

ASSIGNMENT:

Within your locality get the different types of soil.

READING ASSIGNMENT:

The students should read about Building foundation NERDC Basic Technology for Junior Secondary School 3

WEEK 7

TOPIC: BUILDING

SUB-TOPICS:

• Floors

• Doors, windows and Openings

Sub-Topic 1: FLOOR

Floors

Floors are the horizontal components of buildings that support all imposed load. Floors normally satisfy a number of requirements depending on their location.

Types of Floors.

a. Solid Floors: Solid floors usually consist of concrete, which may simply be finished with a smooth surface or laid with tiles (plastic and linoleum floor tiles), which are not normally laid down in the specifications.

b. Suspended Floors: These consist of wood, which are nailed over solid lengths of timber, the ends of which are supported by the many walls of the building. These solid timbers are known as joists, and they vary according to the type of house.

Suspended timber ground floors are susceptible to dry rot, because of lack of ventilation. This situation of fungus attack could be overcome by providing air bricks in the external walls at suitable distances around the perimeter of the building.

Types of floor based on method of construction:

1. The Basement floor: This is the floor below ground level and is used mostly for car parks.

2. The Ground floor: This is floor on ground level.

3. The Upper floor: This is the floor above the ground level.

Damp proof course (D.P.C): It is a layer of material capable of preventing the penetration of moisture which is embedded in the walls just below the exposed surface through which water can percolate. A properly placed D.P.C will prevent blistering of paint, rotting of timber and bulging of plaster.

General floor finishes.

a. Cement screed: this is a mixture of cement and sand and is common for most ordinary dwelling houses. Carpet or linoleum is usually used on such floors. They can also be painted.

b. Floor tiles: A variety of tiles made of wood, ceramics and thermoplastics are available for floor finishes.

c. Terrazzo : This is a very good but costly finish and is used for high class jobs.

d. Timber: Timber is also used and requires to be polished.

Evaluation

• Name the various types of floors

• What is D.P.C?

• Of what importance is D.P.C in building?

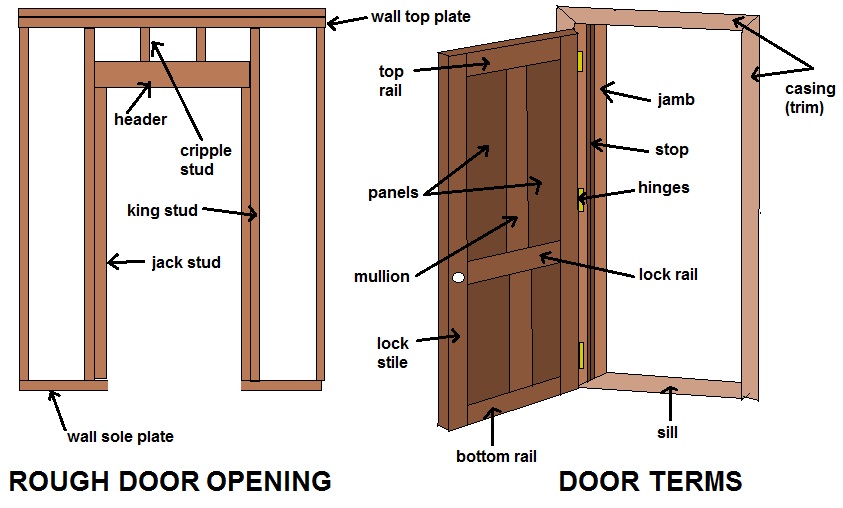

Sub-Topic 2: Doors, Windows and Openings.

A door is a solid flat barrier that closes the opening entrance to a building or a room. The principal function of a door to a building is to prevent unrestricted access to an enclosed space. In other words, entrances and exits into and from buildings, rooms, etc are possible only through doors.

Functions of doors

• They provide inlets and out-lets to the building and its various compartments or rooms.

• They provide security to the building. Unwanted elements (e.g mosquitoes, wild animals, thieves etc) can be shut off.

• Doors contribute to the beauty of the building.

Types of doors: Interior doors and exterior doors.

Interior doors: there are four types of doors generally used as interior doors, they are:

Panel door ii. Flush door iii. French door iv. Louvre door

Exterior doors: Usually exterior doors are of solid core construction. They may be wooden or glass doors, they may be panel or flush doors.

Sliding door: these are space saving doors which are used for closets in bedrooms, etc their installation usually requires the making of special panels by the craftsman, with the manufacturers providing the tracks and other necessary hardwares.

Revolving doors: these are usually traffic control doors within a building. The door normalizes inward and outward movements with its four leaves revolving on a pivot, thereby allowing a person in and out in turns.

Folding door or Roller shutter door: these are doors which are easily installed, as they take little space. These types of doors are mostly made of metals.

Door sizes

Door can be made to any specified size depending on the use and choice of the designer or owner. Some standard sizes include:

826 x 2049mm. Usually used as external doors.

726 x 2040mm. Suitable for most internal doors.

626 x 2040mm. Usually used for cupboards and cloakrooms.

526 x 2040mm.Usually used for small cupboards.

The normal thickness of the above door size is usually 40mm.

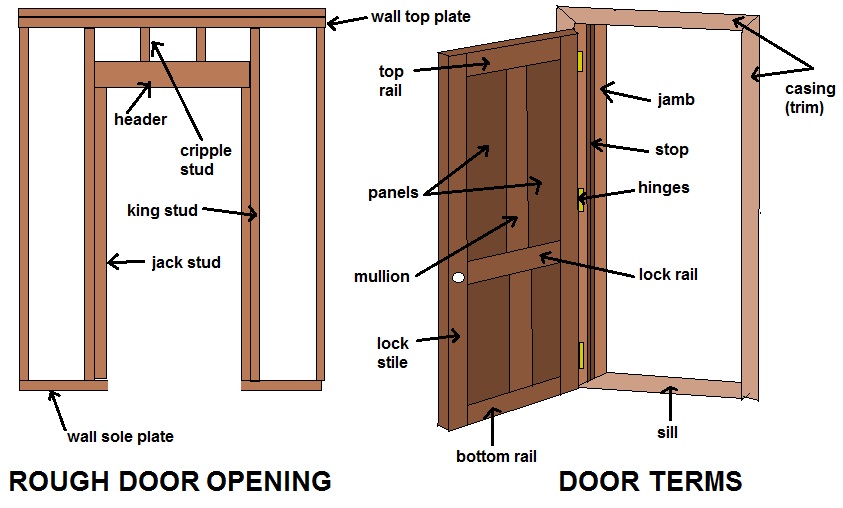

Door frames

A door-set consists of a door plus the frame. It is the frame which holds the door in position so that it can open or close. The frame is normally fixed in position either during the construction of the wall or thereafter. A frame consists of three members, these are two posts which are secured at the top to a cross-piece called the head. The head usually has horns which are some 50 to 100 mm projections of the head beyond the posts. The horns assist in making the frame secure when it is built into the wall. In order that the door may be well received by the frame, a 13 to 16mm deep recess or rebate is formed round the frame.

Mounting of doors.

Doors are mounted on frames which are already positioned on the walls by the use of hardwares such as hinges and fittings such as bolts and locks. It also includes door handles or knobs.

Window: A window is an opening in wall, designed for the purpose of admitting light and air into an enclosed space. Occupants of a building can also have an outside view through the window. Majority of today’s designs emphasize windows as decorative structures, as portrayed by their shapes and sizes, which are better installed into frames.

Types of windows:

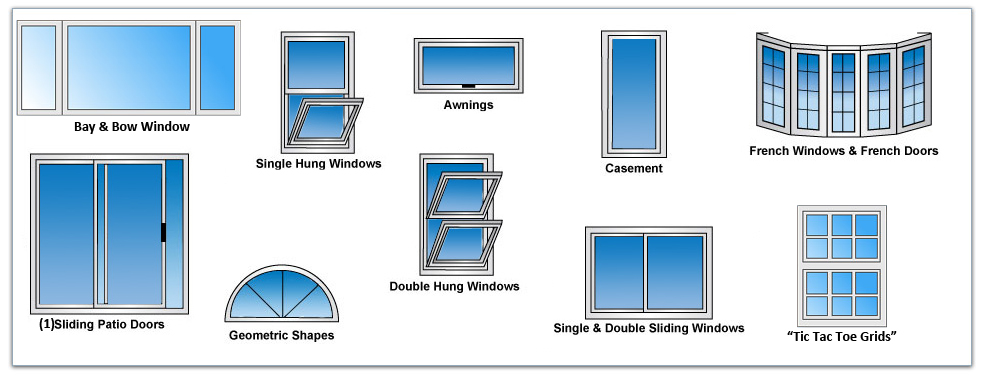

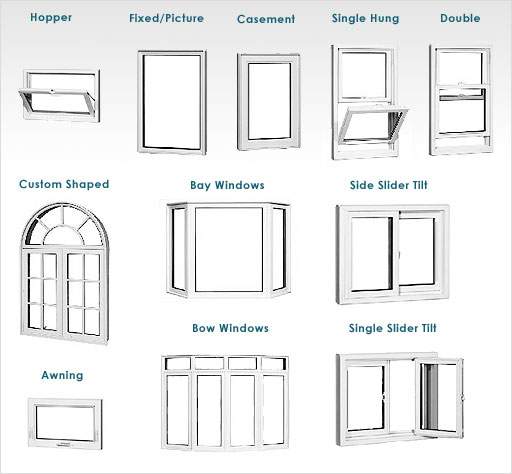

i. Casement window ii. Louvered window iii. Double hung window iv. French window v. Hopper window vi. Sliding window

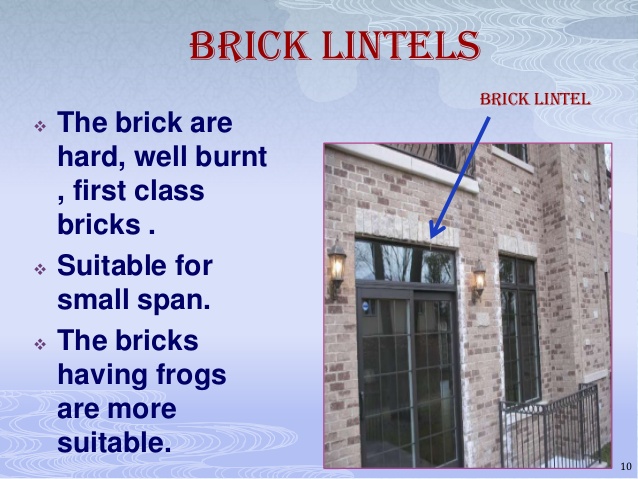

Lintel: A lintel is a horizontal beam supporting a wall over an opening of relatively short span. The lintel spans an opening to carry the load above the opening and to transmit the same load to the wall on either side of the opening. A lintel could be of concrete, wood or metal.

Functions of Lintel

(i) Lintel is used to support wall block/bricks set above the openings. Such as doors and windows.